PUBLISHER: Global Market Insights Inc. | PRODUCT CODE: 1876621

PUBLISHER: Global Market Insights Inc. | PRODUCT CODE: 1876621

Electric Vehicle Battery Management Chips Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034

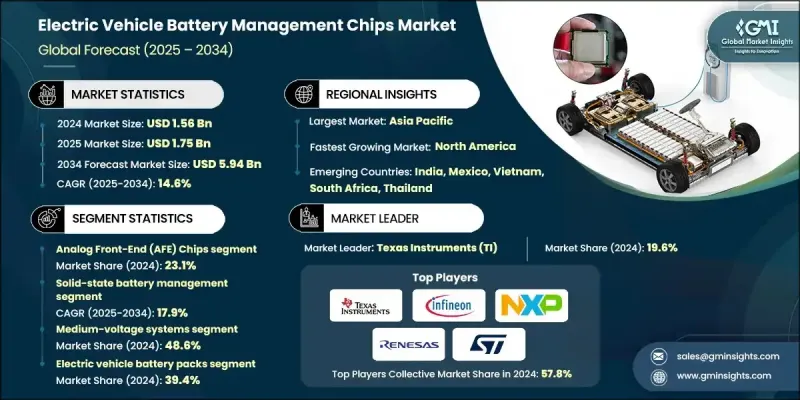

The Global Electric Vehicle Battery Management Chips Market was valued at USD 1.56 billion in 2024 and is estimated to grow at a CAGR of 14.6% to reach USD 5.94 billion by 2034.

Growing emphasis on battery safety continues to fuel market adoption as manufacturers seek to reduce the risks associated with overheating, short-circuiting, and overcharging. These chips continuously monitor cell conditions within the battery pack, ensuring reliable performance and operational safety. As global safety standards become increasingly strict, automotive companies are investing heavily in next-generation management chips to enhance protection, extend battery life, and boost consumer confidence. In addition to safety improvements, the rapid surge in electric vehicle demand-driven by environmental priorities, government incentives, and emission reduction mandates-remains a crucial market catalyst. Battery management chips play a vital role in optimizing power efficiency, regulating charge cycles, and preventing failures. The integration of advanced monitoring capabilities and predictive maintenance systems is transforming battery management into a highly data-driven process. With the rise of connected and autonomous vehicles, manufacturers are focusing on chips that can deliver enhanced communication, energy optimization, and diagnostic features. This convergence of safety, efficiency, and digitalization is set to propel sustained market expansion throughout the forecast period.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $1.56 Billion |

| Forecast Value | $5.94 Billion |

| CAGR | 14.6% |

The Analog Front-End (AFE) chips segment held a 23.1% share in 2024 and is expected to witness a CAGR of 13.4% through 2034. AFE chips serve as critical interfaces between battery cells and the digital controller, accurately converting analog signals such as voltage and temperature into digital data for precise monitoring and control. Modern AFE components demand high measurement accuracy, ensuring optimal performance and stability across voltage ranges and rapid measurement windows.

The solid-state battery management segment will grow at a CAGR of 17.9% from 2025 to 2034. Solid-state battery systems utilize non-flammable solid electrolytes instead of liquid ones, offering significant improvements in safety, energy density, cycle life, and temperature tolerance. These batteries can achieve energy densities exceeding 400 Wh/kg and provide longer operational lifespans, driving the need for sophisticated battery management chips capable of handling their unique electrical characteristics.

United States Electric Vehicle Battery Management Chips Market held an 87.4% share in 2024. Supportive federal policies, tax incentives, and initiatives aimed at advancing domestic production have significantly strengthened the country's EV ecosystem. Legislative measures promoting clean energy and manufacturing innovation continue to bolster local chip development, mitigating potential supply chain disruptions. U.S. manufacturers are integrating artificial intelligence and predictive analytics into their battery management systems to improve performance, enhance real-time monitoring, and extend the overall lifespan of batteries, which further supports the industry's evolution toward intelligent energy systems.

Major companies operating in the Global Electric Vehicle Battery Management Chips Market include STMicroelectronics (ST), NXP Semiconductors, Texas Instruments (TI), Microchip Technology, Infineon Technologies, ABLIC Inc., Rohm Co. Ltd, Nisshinbo Micro Devices, and Renesas Electronics. Leading companies in the Electric Vehicle Battery Management Chips Market are focusing on product innovation, collaboration, and strategic expansion to reinforce their market presence. Firms are investing in research and development to design high-efficiency, low-power chips that enhance energy management and improve safety standards. Partnerships with automotive OEMs and battery producers are enabling customized chip integration for next-generation electric vehicles. Many players are adopting AI-powered monitoring solutions to enable predictive diagnostics and real-time optimization. Expansion into regional manufacturing hubs and vertical integration within the supply chain are key strategies to ensure reliability and cost efficiency. Sustainability and smart energy management are central to corporate initiatives aimed at strengthening competitiveness and supporting the global transition toward electrified mobility.

Table of Contents

Chapter 1 Methodology

- 1.1 Market scope and definition

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Data mining sources

- 1.3.1 Global

- 1.3.2 Regional/Country

- 1.4 Base estimates and calculations

- 1.4.1 Base year calculation

- 1.4.2 Key trends for market estimation

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.6 Forecast

- 1.7 Research assumptions and limitations

Chapter 2 Executive Summary

- 2.1 Industry 360° synopsis, 2021 - 2034

- 2.2 Key market trends

- 2.2.1 Technology

- 2.2.2 Battery

- 2.2.3 Voltage range

- 2.2.4 Integration level

- 2.2.5 Application

- 2.2.6 Vehicle

- 2.2.7 Regional

- 2.3 TAM Analysis, 2025-2034

- 2.4 CXO perspectives: Strategic imperatives

- 2.4.1 Executive decision points

- 2.4.2 Critical success factors

- 2.5 Future outlook and strategic recommendations

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Value Chain Analysis & Industry Structure

- 3.1.1.1 Raw Materials & Wafer Fabrication

- 3.1.1.2 BMS IC Design & Development

- 3.1.1.3 Semiconductor Manufacturing & Testing

- 3.1.1.4 BMS Module Assembly & Integration

- 3.1.1.5 Battery Pack Integration & Validation

- 3.1.1.6 OEM Vehicle Integration & Deployment

- 3.1.1.7 Aftermarket & Service Ecosystem

- 3.1.1.8 End-of-Life Recycling & Sustainability

- 3.1.1 Value Chain Analysis & Industry Structure

- 3.2 Supplier landscape

- 3.2.1 Raw material suppliers

- 3.2.2 Component manufacturers

- 3.2.3 Battery manufacturers

- 3.2.4 System integrators

- 3.2.5 OEM

- 3.2.6 End use

- 3.3 Industry impact forces

- 3.3.1 Growth drivers

- 3.3.1.1 Electric Vehicle Market Proliferation

- 3.3.1.2 Battery Safety & Regulatory Requirements

- 3.3.1.3 Energy Density & Performance Optimization Demand

- 3.3.1.4 Fast Charging Infrastructure Development

- 3.3.1.5 Grid Energy Storage Market Growth

- 3.3.2 Industry pitfalls and challenges

- 3.3.2.1 High Development & Qualification Costs

- 3.3.2.2 Complex Multi-Cell Monitoring Challenges

- 3.3.3 Market opportunities

- 3.3.3.1 Solid-State Battery Technology Integration

- 3.3.3.2 Wireless Battery Management Systems

- 3.3.3.3 AI-Enhanced Battery Optimization

- 3.3.3.4 Second-Life Battery Applications

- 3.3.1 Growth drivers

- 3.4 Growth potential analysis

- 3.5 Regulatory landscape

- 3.5.1 North America

- 3.5.2 Europe

- 3.5.3 Asia Pacific

- 3.5.4 Latin America

- 3.5.5 Middle East and Africa

- 3.6 Porter's analysis

- 3.7 PESTEL analysis

- 3.8 Technology and Innovation landscape

- 3.8.1 Current technology

- 3.8.2 Emerging technology

- 3.9 Patent analysis

- 3.10 Price Trends Analysis

- 3.10.1 By product

- 3.10.2 By region

- 3.11 Cost Breakdown Analysis

- 3.12 Production staistics

- 3.12.1 Production hubs

- 3.12.2 Consumption hubs

- 3.12.3 Export and import

- 3.13 Sustainability and Environmental Aspects

- 3.13.1 Sustainable Practices

- 3.13.2 Waste Reduction Strategies

- 3.13.3 Energy Efficiency in Production

- 3.13.4 Eco-friendly Initiatives

- 3.13.5 Carbon Footprint Considerations

- 3.14 Market Maturity & Adoption Analysis

- 3.14.1 Technology Readiness Level Assessment

- 3.14.2 Regional Adoption Maturity Comparison

- 3.14.3 Application Domain Maturity Analysis

- 3.14.4 Manufacturing Readiness & Scale Assessment

- 3.14.5 Commercial Deployment Timeline

- 3.15 Total Cost of Ownership (TCO) Analysis

- 3.15.1 BMS Chip Component Costs

- 3.15.2 System Integration & Development Expenses

- 3.15.3 Automotive Qualification & Testing Costs

- 3.15.4 Manufacturing & Deployment Expenses

- 3.15.5 Maintenance & Replacement Lifecycle Costs

- 3.15.6 TCO Comparison by Technology Type

- 3.16 Integration Complexity & Implementation Challenges

- 3.16.1 Multi-Cell Architecture Design Challenges

- 3.16.2 High-Voltage Isolation & Safety Requirements

- 3.16.3 Communication Protocol Integration

- 3.16.4 Thermal Management & Heat Dissipation

- 3.16.5 Software Integration & Algorithm Development

- 3.17 Manufacturing Process & Quality Control Analysis

- 3.17.1 Semiconductor Fabrication & Yield Optimization

- 3.17.2 Automotive-Grade Testing & Qualification

- 3.17.3 Quality Assurance & Reliability Testing

- 3.17.4 Supply Chain Management & Sourcing

- 3.17.5 Cost Reduction & Process Optimization

- 3.18 Safety & Functional Safety Framework Analysis

- 3.18.1 ISO 26262 ASIL Compliance Requirements

- 3.18.2 Battery Safety Standards & Regulations

- 3.18.3 Failure Mode Analysis & Prevention

- 3.18.4 Redundancy & Fault Tolerance Design

- 3.18.5 Cybersecurity & Data Protection

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.2.1 North America

- 4.2.2 Europe

- 4.2.3 Asia Pacific

- 4.2.4 LATAM

- 4.2.5 MEA

- 4.3 Competitive analysis of major market players

- 4.4 Competitive positioning matrix

- 4.5 Strategic outlook matrix

- 4.6 Key news and initiatives

- 4.6.1 Mergers & acquisitions

- 4.6.2 Partnerships & collaborations

- 4.6.3 New Product Launches

- 4.6.4 Expansion Plans and funding

Chapter 5 Market Estimates & Forecast, By Technology, 2021 - 2034 ($Bn, Units)

- 5.1 Key trends

- 5.2 Analog Front-End (AFE) chips

- 5.3 Cell Monitoring ICs

- 5.4 Battery balancing circuits

- 5.5 Protection ICs

- 5.6 Battery management controllers

- 5.7 Current sensing ICs

Chapter 6 Market Estimates & Forecast, By Battery, 2021 - 2034 ($Bn, Units)

- 6.1 Key trends

- 6.2 Lithium-ion battery management

- 6.3 Lithium iron phosphate management

- 6.4 Solid-state battery management

- 6.5 Nickel-metal hydride management

- 6.6 Advanced chemistry support

Chapter 7 Market Estimates & Forecast, By Voltage Range, 2021 - 2034 ($Bn, Units)

- 7.1 Key trends

- 7.2 Low-voltage system

- 7.3 Medium-voltage system

- 7.4 High-voltage system

- 7.5 Ultra-high voltage system

Chapter 8 Market Estimates & Forecast, By Integration level, 2021 - 2034 ($Bn, Units)

- 8.1 Key trends

- 8.2 Discrete component

- 8.3 Integrated solution

- 8.4 System-on-Chip (SoC)

- 8.5 Modular system

Chapter 9 Market Estimates & Forecast, By Application, 2021 - 2034 ($Bn, Units)

- 9.1 Key trends

- 9.2 Electric vehicle battery packs

- 9.3 Hybrid electric vehicle systems

- 9.4 Energy storage systems

- 9.5 Charging infrastructure

- 9.6 Auxiliary battery systems

- 9.7 Portable energy storage

Chapter 10 Market Estimates & Forecast, By Vehicle, 2021 - 2034 ($Bn, Units)

- 10.1 Key trends

- 10.2 Passenger EVs

- 10.2.1 BEV

- 10.2.2 PHEV

- 10.2.3 FCEV

- 10.3 Commercial EV

- 10.3.1 Vans

- 10.3.1.1 BEV

- 10.3.1.2 PHEV

- 10.3.2 Buses

- 10.3.2.1 BEV

- 10.3.2.2 FCEV

- 10.3.3 Trucks

- 10.3.3.1 BEV

- 10.3.3.2 FCEV

- 10.3.1 Vans

Chapter 11 Market Estimates & Forecast, By Region, 2021 - 2034 ($Bn, Units)

- 11.1 Key trends

- 11.2 North America

- 11.2.1 US

- 11.2.2 Canada

- 11.3 Europe

- 11.3.1 Germany

- 11.3.2 UK

- 11.3.3 France

- 11.3.4 Italy

- 11.3.5 Spain

- 11.3.6 Nordics

- 11.3.7 Netherlands

- 11.3.8 Russia

- 11.4 Asia Pacific

- 11.4.1 China

- 11.4.2 India

- 11.4.3 Japan

- 11.4.4 Australia

- 11.4.5 South Korea

- 11.4.6 Singapore

- 11.4.7 Vietnam

- 11.4.8 Indonesia

- 11.5 Latin America

- 11.5.1 Brazil

- 11.5.2 Colombia

- 11.5.3 Costa Rica

- 11.5.4 Mexico

- 11.5.5 Argentina

- 11.6 MEA

- 11.6.1 South Africa

- 11.6.2 Saudi Arabia

- 11.6.3 UAE

Chapter 12 Company Profiles

- 12.1 Global Players

- 12.1.1 Texas Instruments Incorporated

- 12.1.2 Analog Devices

- 12.1.3 Infineon Technologies

- 12.1.4 NXP Semiconductors

- 12.1.5 STMicroelectronics

- 12.1.6 Renesas Electronics

- 12.1.7 Maxim Integrated Products (Analog Devices)

- 12.1.8 ON Semiconductor Corporation

- 12.1.9 Microchip Technology

- 12.2 Regional Champions

- 12.2.1 Tesla

- 12.2.2 General Motors

- 12.2.3 Ford Motor

- 12.2.4 BYD

- 12.2.5 Contemporary Amperex Technology (CATL)

- 12.2.6 LG

- 12.2.7 Panasonic

- 12.2.8 Samsung

- 12.3 Emerging Players & Specialists

- 12.3.1 Monolithic Power Systems

- 12.3.2 Linear Technology (Analog Devices)

- 12.3.3 Intersil Corporation (Renesas)

- 12.3.4 Richtek Technology Corporation

- 12.3.5 Diodes Incorporated

- 12.3.6 ROHM Semiconductor

- 12.3.7 Cypress Semiconductor (Infineon)

- 12.3.8 Semtech Corporation