PUBLISHER: Global Market Insights Inc. | PRODUCT CODE: 1885812

PUBLISHER: Global Market Insights Inc. | PRODUCT CODE: 1885812

Carbon Capture Utilization Chemicals Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034

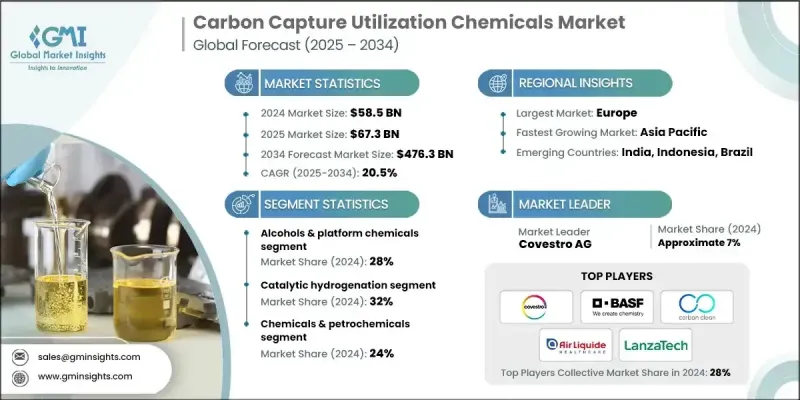

The Global Carbon Capture Utilization Chemicals Market was valued at USD 58.5 billion in 2024 and is estimated to grow at a CAGR of 20.5% to reach USD 476.3 billion by 2034.

Companies across the world are prioritizing low-carbon and carbon-negative materials as part of their long-term net-zero strategies, leading to rising demand for solutions produced from captured carbon dioxide. Manufacturers are broadening procurement goals for lower-emission materials, and multiple industries are adopting CO2-based products to cut supply-chain emissions. Accelerated advancements in catalysis, electrolysis, and system integration are lowering costs and improving performance, supported by emerging catalyst technologies that deliver stronger efficiency and stability in CO2 conversion. High-performance electrolysis systems are achieving increased current densities, which reduces capital investment through compact system design. The market is also shifting from small-scale demonstrations to full commercial operations, with integrated production models combining renewable hydrogen, concentrated CO2 sources, and bioenergy systems to create powerful pathways for deployment.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $58.5 Billion |

| Forecast Value | $476.3 Billion |

| CAGR | 20.5% |

The alcohols and platform chemicals segment held 28% share in 2024 and is projected to grow at a 23% CAGR by 2034. This outlook is linked to expanding production of methanol and ethanol derived from captured CO2 and renewable hydrogen. Commercial facilities in multiple regions are already producing renewable methanol that serves as a key feedstock for chemical and fuel markets.

The catalytic hydrogenation segment accounted for 32% share in 2024 and is anticipated to grow at a CAGR of 22.5% through 2034. Its commercial potential is supported by mature catalyst systems, well-defined process designs, and proven industrial implementation. Next-generation methanol synthesis catalysts featuring Cu, ZnO, and Al2O3 compositions are reaching selectivity levels above 99% while achieving yields like conventional processes. Catalyst systems based on cobalt and iron enable the conversion of CO2-derived syngas into synthetic hydrocarbons, with output tailored by adjusting operating conditions.

The construction segment held 20% share in 2024 and is projected to grow at a CAGR of 25%. Demand growth is driven by expanding adoption of CO2-enhanced concrete materials and low-carbon cement. Increasing investments in infrastructure across major regions are incorporating stricter specifications for lower-emission building inputs, which is strengthening market momentum.

Europe Carbon Capture Utilization Chemicals Market held 32% share in 2024, supported by major climate policies designed to promote large-scale carbon management. Regional initiatives aim to expand CO2 storage capacity to 50 million tons per year by 2030, alongside long-term plans to develop a cross-border CO2 commodity market by 2040 targeting 280 million tons in annual capture.

Prominent companies operating in the Global Carbon Capture Utilization Chemicals Market include Climeworks AG, Aker Carbon Capture ASA, Carbon Upcycling Technologies Inc., Covestro AG, Air Liquide S.A., Liquid Wind AB, Econic Technologies Ltd., Blue Planet Systems Corporation, Carbon Recycling International (CRI), SK Innovation Co., Ltd., TotalEnergies SE, CarbonCure Technologies Inc., BASF SE, LanzaTech Global, Inc., Solidia Technologies, Inc., Avantium N.V., Carbon Clean Solutions Ltd., Mitsubishi Chemical Group Corporation, Novomer Inc., and SABIC. Leading players in the Carbon Capture Utilization Chemicals Market are strengthening their competitive position by scaling commercial production capacity, forming long-term partnerships across industrial value chains, and investing heavily in next-generation catalyst and electrolysis technologies. Many companies are also optimizing integrated systems that combine captured CO2 with renewable hydrogen to reduce production costs and improve system efficiency. Strategic collaborations with energy, chemical, and construction firms help streamline offtake agreements and secure stable demand.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Market scope and definition

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Data mining sources

- 1.3.1 Global

- 1.3.2 Regional/Country

- 1.4 Base estimates and calculations

- 1.4.1 Base year calculation

- 1.4.2 Key trends for market estimation

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.6 Forecast model

- 1.7 Research assumptions and limitations

Chapter 2 Executive Summary

- 2.1 Industry 3600 synopsis

- 2.2 Key market trends

- 2.2.1 Regional

- 2.2.2 Product Type

- 2.2.3 Technology

- 2.2.4 End Use Industry

- 2.3 TAM Analysis, 2025-2034

- 2.4 CXO perspectives: Strategic imperatives

- 2.4.1 Executive decision points

- 2.4.2 Critical success factors

- 2.5 Future Outlook and Strategic Recommendations

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Supplier landscape

- 3.1.2 Profit margin

- 3.1.3 Value addition at each stage

- 3.1.4 Factor affecting the value chain

- 3.1.5 Disruptions

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.2 Industry pitfalls and challenges

- 3.2.3 Market opportunities

- 3.3 Growth potential analysis

- 3.4 Regulatory landscape

- 3.4.1 North America

- 3.4.2 Europe

- 3.4.3 Asia Pacific

- 3.4.4 Latin America

- 3.4.5 Middle East & Africa

- 3.5 Porter's analysis

- 3.6 PESTEL analysis

- 3.7 Price trends

- 3.7.1 By region

- 3.7.2 By Product type

- 3.8 Future market trends

- 3.9 Technology and Innovation landscape

- 3.9.1 Current technological trends

- 3.9.2 Emerging technologies

- 3.10 Patent Landscape

- 3.11 Trade statistics (HS code) ( Note: the trade statistics will be provided for key countries only)

- 3.11.1 Major importing countries

- 3.11.2 Major exporting countries

- 3.12 Sustainability and environmental aspects

- 3.12.1 Sustainable practices

- 3.12.2 Waste reduction strategies

- 3.12.3 Energy efficiency in production

- 3.12.4 Eco-friendly initiatives

- 3.13 Carbon footprint consideration

Chapter 4 Competitive Landscape, 2024

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.2.1 By region

- 4.2.1.1 North America

- 4.2.1.2 Europe

- 4.2.1.3 Asia Pacific

- 4.2.1.4 LATAM

- 4.2.1.5 MEA

- 4.2.1 By region

- 4.3 Company matrix analysis

- 4.4 Competitive analysis of major market players

- 4.5 Competitive positioning matrix

- 4.6 Key developments

- 4.6.1 Mergers & acquisitions

- 4.6.2 Partnerships & collaborations

- 4.6.3 New Product Launches

- 4.6.4 Expansion Plans

Chapter 5 Market Estimates and Forecast, By Product Type, 2021-2034 (USD Billion) (Kilo Tons)

- 5.1 Key trends

- 5.2 Alcohols & platform chemicals

- 5.3 Polymers & plastics

- 5.4 Olefins & hydrocarbons

- 5.5 Syngas & intermediates

- 5.6 Building materials & aggregates

- 5.7 Specialty & other chemicals

Chapter 6 Market Estimates and Forecast, By Technology, 2021-2034 (USD Billion) (Kilo Tons)

- 6.1 Key trends

- 6.2 Electrochemical conversion

- 6.3 Catalytic hydrogenation

- 6.4 Gas fermentation & biological conversion

- 6.5 Thermochemical conversion

- 6.6 Mineralization & carbonation

- 6.7 Direct chemical synthesis

Chapter 7 Market Estimates and Forecast, By End Use Industry, 2021-2034 (USD Billion) (Kilo Tons)

- 7.1 Key trends

- 7.2 Automotive

- 7.2.1 Interior components

- 7.2.2 Exterior components

- 7.2.3 Under-the-hood applications

- 7.3 Construction & building

- 7.3.1 Residential construction

- 7.3.2 Commercial buildings

- 7.3.3 Infrastructure & civil engineering

- 7.4 Packaging

- 7.4.1 Food & beverage packaging

- 7.4.2 Industrial packaging

- 7.4.3 Consumer goods packaging

- 7.5 Chemicals & petrochemicals

- 7.5.1 Base chemicals production

- 7.5.2 Specialty chemicals

- 7.5.3 Agrochemicals

- 7.6 Aviation

- 7.6.1 Commercial aviation

- 7.6.2 Cargo & freight

- 7.6.3 Military & defense

- 7.7 Healthcare

- 7.7.1 Medical devices

- 7.7.2 Pharmaceutical packaging

- 7.7.3 Hospital & clinical supplies

- 7.8 Agriculture

- 7.8.1 Crop production

- 7.8.2 Fertilizers & soil amendments

- 7.8.3 Agricultural equipment

- 7.9 Electronics & consumer goods

- 7.9.1 Consumer electronics

- 7.9.2 Home appliances

- 7.9.3 Sporting goods

Chapter 8 Market Estimates and Forecast, By Region, 2021-2034 (USD Billion) (Kilo Tons)

- 8.1 Key trends

- 8.2 North America

- 8.2.1 U.S.

- 8.2.2 Canada

- 8.3 Europe

- 8.3.1 Germany

- 8.3.2 UK

- 8.3.3 France

- 8.3.4 Spain

- 8.3.5 Italy

- 8.3.6 Rest of Europe

- 8.4 Asia Pacific

- 8.4.1 China

- 8.4.2 India

- 8.4.3 Japan

- 8.4.4 Australia

- 8.4.5 South Korea

- 8.4.6 Rest of Asia Pacific

- 8.5 Latin America

- 8.5.1 Brazil

- 8.5.2 Mexico

- 8.5.3 Argentina

- 8.5.4 Rest of Latin America

- 8.6 Middle East and Africa

- 8.6.1 Saudi Arabia

- 8.6.2 South Africa

- 8.6.3 UAE

- 8.6.4 Rest of Middle East and Africa

Chapter 9 Company Profiles

- 9.1 Air Liquide S.A.

- 9.2 Aker Carbon Capture ASA

- 9.3 Avantium N.V.

- 9.4 BASF SE

- 9.5 Blue Planet Systems Corporation

- 9.6 Carbon Clean Solutions Ltd.

- 9.7 Carbon Recycling International (CRI)

- 9.8 Carbon Upcycling Technologies Inc.

- 9.9 CarbonCure Technologies Inc.

- 9.10 Climeworks AG

- 9.11 Covestro AG

- 9.12 Econic Technologies Ltd.

- 9.13 LanzaTech Global, Inc.

- 9.14 Liquid Wind AB

- 9.15 Mitsubishi Chemical Group Corporation

- 9.16 Novomer Inc.

- 9.17 SABIC

- 9.18 SK Innovation Co., Ltd.

- 9.19 Solidia Technologies, Inc.

- 9.20 TotalEnergies SE

- 9.21 Others