PUBLISHER: Global Market Insights Inc. | PRODUCT CODE: 1928866

PUBLISHER: Global Market Insights Inc. | PRODUCT CODE: 1928866

Cold Gas Spray Coating Services Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2026 - 2035

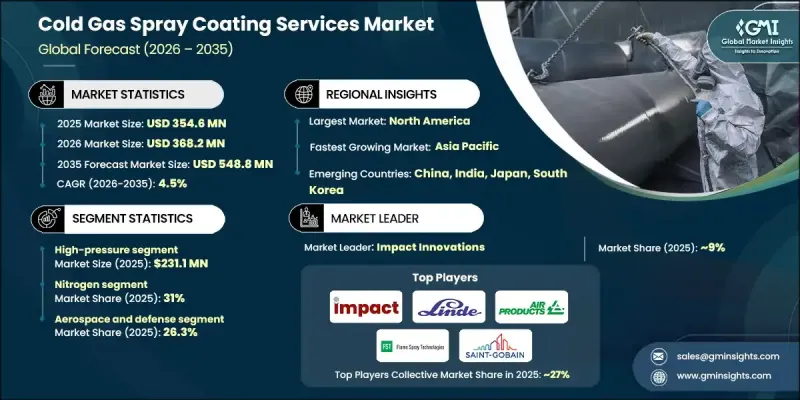

The Global Cold Gas Spray Coating Services Market was valued at USD 354.6 million in 2025 and is estimated to grow at a CAGR of 4.5% to reach USD 548.8 million by 2035.

Market expansion is stated to be supported by rising disposable income levels and the ongoing shift toward premiumization within personal care product consumption. Consumers are described as showing a greater willingness to spend on higher-quality tools that deliver improved performance, durability, and user comfort. Increased purchasing power is enabling households to replace entry-level products with higher-grade alternatives designed for long-term use. Professional users are also contributing to demand growth by prioritizing advanced equipment to enhance service quality and customer satisfaction. Brand positioning, continuous innovation, and broader product availability across physical and digital retail platforms are shaping buying behavior. At the same time, strong demand for component restoration and extended service life in industrial sectors is accelerating the adoption of cold gas spray coating services. Industries with high-value assets prefer repair solutions over full replacement to reduce costs and downtime. Cold gas spray processes are favored for their ability to apply coatings without heat-related distortion, ensuring that original material characteristics remain intact. This capability supports precise correction of surface degradation, corrosion, and dimensional wear across multiple applications.

| Market Scope | |

|---|---|

| Start Year | 2025 |

| Forecast Year | 2026-2035 |

| Start Value | $354.6 Million |

| Forecast Value | $548.8 Million |

| CAGR | 4.5% |

The high-pressure segment generated USD 213.1 million in 2025 and is forecast to grow at a CAGR of 4.6% from 2026 through 2035. This segment is portrayed as leading the overall market due to its effectiveness in producing dense coatings with strong bonding strength across diverse materials. High-pressure systems are widely utilized for repair, refurbishment, and surface reinforcement where accuracy and mechanical reliability are critical. The process allows controlled material application while maintaining the underlying structure, which reinforces its preference across demanding operational environments.

The nitrogen segment held 31% share in 2025. Its dominance is attributed to stable performance, operational safety, and compatibility with a broad range of coating materials. The use of nitrogen supports clean deposition while minimizing unwanted chemical interaction with substrates. Consistent supply and comparatively efficient operating economics further strengthen its position across service providers.

United States Cold Gas Spray Coating Services Market reached USD 86.9 million in 2025 with a projected CAGR of 4.6% from 2026 to 2035. Market demand within the country is driven by ongoing requirements for restoration, protection, and performance enhancement of critical components across multiple industrial sectors. Service providers delivering high-precision coating solutions with limited thermal impact are experiencing sustained demand as asset owners seek reliable methods to extend equipment lifespan and maintain operational efficiency.

Key participants active in the Global Cold Gas Spray Coating Services Market include Air Products and Chemicals, ASB, ASB Industries, Bodycote, Curtiss-Wright Surface Technologies, Flame Spray Technologies, Impact Innovations, Inovati, Integrated Global Services, Linde plc, Oerlikon Metco, Plasma Giken Co., Saint-Gobain, TWI Ltd., and VRC Metal Systems. These companies are recognized for their technical expertise, service capabilities, and ongoing investments in process development. Companies operating in the Global Cold Gas Spray Coating Services Market are strengthening their market position through a combination of technological advancement, capacity expansion, and strategic partnerships. Many providers are investing in advanced equipment to improve coating quality, consistency, and application speed. Expanding service portfolios to address a wider range of materials and repair requirements is also a key focus area. Firms are enhancing geographic reach by establishing new service centers closer to end users to reduce turnaround time.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Market scope and definition

- 1.2 Research design

- 1.2.1 Research approach

- 1.2.2 Data collection methods

- 1.3 Data mining sources

- 1.3.1 Global

- 1.3.2 Regional/Country

- 1.4 Base estimates and calculations

- 1.4.1 Base year calculation

- 1.4.2 Key trends for market estimation

- 1.5 Primary research and validation

- 1.5.1 Primary sources

- 1.6 Forecast model

- 1.7 Research assumptions and limitations

Chapter 2 Executive Summary

- 2.1 Industry 360° synopsis

- 2.2 Key market trends

- 2.2.1 Regional

- 2.2.2 Technology

- 2.2.3 Gas type

- 2.2.4 Material

- 2.2.5 End use

- 2.2.6 Service offerings

- 2.3 CXO perspectives: Strategic imperatives

- 2.3.1 Key decision points for industry executives

- 2.3.2 Critical success factors for market players

- 2.4 Future outlook and strategic recommendations

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.1.1 Supplier landscape

- 3.1.2 Profit margin

- 3.1.3 Value addition at each stage

- 3.1.4 Factor affecting the value chain

- 3.2 Industry impact forces

- 3.2.1 Growth drivers

- 3.2.1.1 Rising demand for component repair and life extension in aerospace and defense

- 3.2.1.2 Growing use of cold spray for corrosion and wear protection

- 3.2.1.3 Expansion of additive repair techniques in heavy industrial equipment

- 3.2.2 Pitfalls & Challenges

- 3.2.2.1 High capital cost of cold gas spray equipment and setup

- 3.2.2.2 Limited availability of skilled operators and process expertise

- 3.2.3 Opportunities

- 3.2.3.1 Growing adoption in automotive and electric vehicle component repair

- 3.2.3.2 Expansion of cold spray applications in oil and gas infrastructure maintenance

- 3.2.1 Growth drivers

- 3.3 Growth potential analysis

- 3.4 Future market trends

- 3.5 Technology and innovation landscape

- 3.5.1 Current technological trends

- 3.5.2 Emerging technologies

- 3.6 Price trends

- 3.6.1 By region

- 3.6.2 By product

- 3.7 Regulatory landscape

- 3.7.1 Standards and compliance requirements

- 3.7.2 Regional regulatory frameworks

- 3.7.3 Certification standards

- 3.8 Porter';s analysis

- 3.9 PESTEL analysis

Chapter 4 Competitive Landscape, 2025

- 4.1 Introduction

- 4.2 Company market share analysis

- 4.2.1 By Region

- 4.2.1.1 North America

- 4.2.1.2 Europe

- 4.2.1.3 Asia Pacific

- 4.2.1.4 Latin America

- 4.2.1.5 Middle East & Africa

- 4.2.1 By Region

- 4.3 Company matrix analysis

- 4.4 Competitive analysis of major market players

- 4.5 Competitive positioning matrix

- 4.6 Key developments

- 4.6.1 Mergers & acquisitions

- 4.6.2 Partnerships & collaborations

- 4.6.3 New product launches

- 4.6.4 Expansion plans

Chapter 5 Market Estimates & Forecast, By Technology, 2022 - 2035, (USD Million) (Thousand Units)

- 5.1 Key trends

- 5.2 High-pressure

- 5.3 Low-pressure

Chapter 6 Market Estimates & Forecast, By Gas Type, 2022 - 2035, (USD Million) (Thousand Units)

- 6.1 Key trends

- 6.2 Nitrogen

- 6.3 Helium

- 6.4 Air

- 6.5 Argon

- 6.6 Mixed gas

Chapter 7 Market Estimates & Forecast, By Material, 2022 - 2035, (USD Million) (Thousand Units)

- 7.1 Key trends

- 7.2 Metals

- 7.2.1 Aluminum

- 7.2.2 Copper

- 7.2.3 Nickel

- 7.2.4 Titanium

- 7.2.5 Others

- 7.3 Polymers

- 7.4 Alloys

- 7.5 Composite materials

Chapter 8 Market Estimates & Forecast, By End Use, 2022 - 2035, (USD Million) (Thousand Units)

- 8.1 Key trends

- 8.2 Aerospace and defense

- 8.3 Automotive

- 8.4 Electrical & electronics

- 8.5 Medical

- 8.6 Energy

- 8.7 Others

Chapter 9 Market Estimates & Forecast, By Service Offerings, 2022 - 2035, (USD Million) (Thousand Units)

- 9.1 Key trends

- 9.2 Onsite

- 9.3 Offsite

Chapter 10 Market Estimates & Forecast, By Region, 2022 - 2035, (USD Million) (Thousand Units)

- 10.1 Key trends

- 10.2 North America

- 10.2.1 U.S.

- 10.2.2 Canada

- 10.3 Europe

- 10.3.1 Germany

- 10.3.2 UK

- 10.3.3 France

- 10.3.4 Italy

- 10.3.5 Spain

- 10.4 Asia Pacific

- 10.4.1 China

- 10.4.2 India

- 10.4.3 Japan

- 10.4.4 South Korea

- 10.4.5 Australia

- 10.5 Latin America

- 10.5.1 Brazil

- 10.5.2 Mexico

- 10.5.3 Argentina

- 10.6 MEA

- 10.6.1 Saudi Arabia

- 10.6.2 UAE

- 10.6.3 South Africa

Chapter 11 Company Profiles

- 11.1 Air Products and Chemicals

- 11.2 ASB

- 11.3 ASB Industries

- 11.4 Bodycote

- 11.5 Curtiss-Wright Surface Technologies

- 11.6 Flame Spray Technologies

- 11.7 Impact Innovations

- 11.8 Inovati

- 11.9 Integrated Global Services

- 11.10 Linde plc

- 11.11 Oerlikon Metco

- 11.12 Plasma Giken Co.

- 11.13 Saint-Gobain

- 11.14 TWI Ltd.

- 11.15 VRC Metal Systems