PUBLISHER: MarketsandMarkets | PRODUCT CODE: 1804838

PUBLISHER: MarketsandMarkets | PRODUCT CODE: 1804838

Fill Finish Manufacturing Market by Product ((Consumables (PFS, Plunger Stopper), Vial, Vial Stoppers, Cartridge, Cell Therapy Bags), Instruments ), Fill Finish Service, End User - Global Forecast to 2030

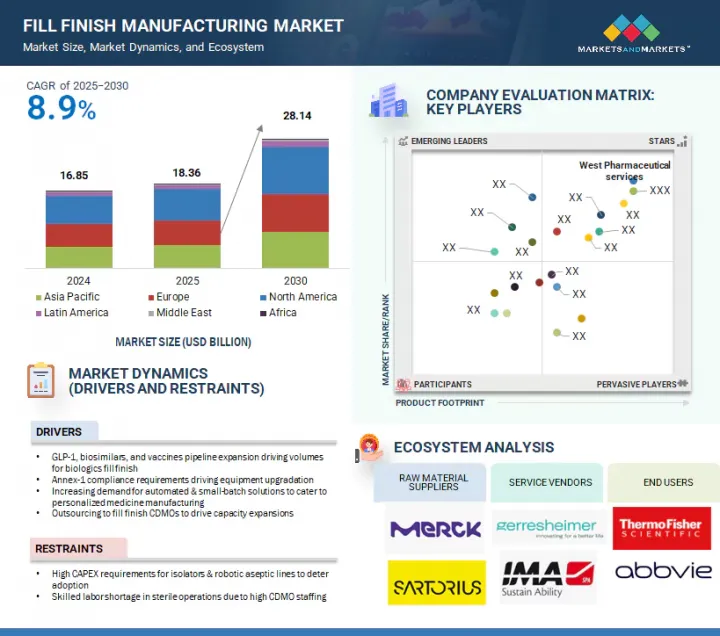

The global fill finish manufacturing market is projected to reach USD 28.14 billion by 2030 from an estimated USD 18.36 billion in 2025, at a CAGR of 8.9% from 2025 to 2030. The expansion of the fill finish manufacturing market has been predominantly fueled by Annex-1 compliance requirements, driving equipment upgradation and increasing demand for automated & small-batch solutions.

| Scope of the Report | |

|---|---|

| Years Considered for the Study | 2024-2030 |

| Base Year | 2024 |

| Forecast Period | 2025-2030 |

| Units Considered | Value (USD billion) |

| Segments | By Product type, End users, and Region |

| Regions covered | North America, Europe, Asia Pacific, Latin America, the Middle East, and Africa |

However, the need for high capex for adoption of isolators and robotic aseptic lines, as well as skilled labor shortage in sterile operations due to high CDMO staffing, is expected to restrain market growth.

"The consumables segment held the highest share in the fill finish manufacturing market by product type."

The fill finish manufacturing market is segmented by product type into consumables and instruments. Consumables held the largest share in the fill finish manufacturing market due to their essential role in ensuring sterility, safety, and efficiency throughout the drug filling and packaging process. These include vials, syringes, cartridges, stoppers, seals, and disposable systems such as tubing, filters, and connectors. With the increasing adoption of prefilled syringes and single-use technologies, the demand for high-quality consumables has surged, particularly for biologics and vaccines that require stringent aseptic conditions. The shift toward ready-to-use (RTU) components, such as pre-washed and sterilized containers and closures in nested & tray formats, further drives the dominance of consumables, as they help reduce contamination risks and streamline operations. Moreover, pharmaceutical manufacturers are prioritizing flexibility and speed to meet global supply demands, making single-use consumables a preferred choice for reducing downtime and cross-contamination. CDMOs and biopharma companies are also increasingly outsourcing fill-finish operations, amplifying the need for standardized and regulatory-compliant consumable products. The growing pipeline of injectable therapies, including monoclonal antibodies, cell and gene therapies, and mRNA-based products, will continue to elevate the demand for high-performance consumables. As a result, consumables are not only indispensable to fill finish workflows but also represent a critical opportunity for innovation and value creation in the evolving pharmaceutical manufacturing landscape.

"CMO segment reported for the highest share of the end user segment in 2024."

The Contract Manufacturing Organizations (CMOs) segment accounted for the largest share of the global fill finish manufacturing market. Based on end users, the market is categorized into CMOs, pharmaceutical and biopharmaceutical companies, and other end users such as Contract Research Organizations (CROs) and academic research institutions. CMOs have gained a strong foothold due to the growing trend of outsourcing fill finish operations, driven by the need for cost-effective and efficient manufacturing solutions. As drug development becomes more complex and time-sensitive, pharmaceutical and biopharmaceutical companies increasingly rely on CMOs to access specialized expertise, reduce capital investment, and accelerate time-to-market while simultaneously reducing costs & freeing up in-house capacity for non-core drugs. CMOs offer advanced capabilities, including aseptic processing, flexibility in batch sizes, and compliance with evolving regulatory standards, making them attractive partners in the highly competitive pharmaceutical landscape. The demand for high-quality, scalable, and reliable manufacturing services continues to rise, particularly for biologics and injectable drugs. As a result, the dominance of CMOs in the fill-finish space is expected to strengthen further, supported by ongoing investment in infrastructure, technology, and global supply chain integration.

"Europe accounted for the highest market share in the global fill finish manufacturing market from 2025 to 2030."

Europe holds the highest market share in the global fill-finish manufacturing market, driven by its strong pharmaceutical and biotechnology infrastructure, well-established regulatory framework, and presence of leading industry players. Countries such as Germany, Switzerland, France, and the UK are home to several top pharmaceutical companies and contract manufacturing organizations (CMOs) that offer advanced fill finish capabilities. The region benefits from significant investments in research and development, high adoption of innovative drug delivery systems, and a growing demand for biologics and personalized medicines. Additionally, Europe's strict regulatory standards promote the use of high-quality, sterile, and compliant fill-finish processes, further boosting the demand for specialized manufacturing solutions. The increasing focus on vaccine production and pandemic preparedness has also enhanced fill finish capacity across the region. Furthermore, government support for pharmaceutical innovation and public-private partnerships continues to strengthen the region's manufacturing capabilities. As a result, Europe remains a dominant force in the fill finish manufacturing landscape, offering growth opportunities for companies with advanced technologies, scalable solutions, and strong quality assurance systems.

The primary interviews conducted for this report can be categorized as follows:

- By Respondent: Supply Side-70% and Demand Side-30%

- By Designation: Managers-45%, CXO and Directors-30%, and Executives-25%

- By Region: North America-30%, Europe-30%, the Asia Pacific-30%, Latin America-5%, and the Middle East & Africa-5%

List of Key Companies Profiled in the Report:

Key players in the fill finish manufacturing market include Syntegon Technology GmbH (Germany), I.M.A. S.P.A. (Italy), BD & Co.(US), West Pharmaceutical Services Inc. (US), Gerresheimer AG (Germany), AptarGroup Inc. (US), Datwyler Holding Inc. (Belgium), Danaher (US), Stevanato Group S.p.A. (Italy), OPTIMA (Germany), Bausch+Strobel (Germany), Groninger & Co. GmbH (Germany), SGD PHARMA (France), SCHOTT (Germany), Nipro Corporation (Japan), Bausch Advanced Technology Group (US), and Maquinaria Industrial Dara SI (Spain).

Research Coverage:

This research report categorizes the fill finish manufacturing market, By Product (Consumables (Pre-fillable Syringes (By components (Pre-fillable Syringe Systems & Components, Plunger Stopper)) By Material (Glass Pre-filled Syringes, Polymer Pre-filled Syringes)), Vial (By Material (Glass Vials, Polymer Vials), By Format (Bulk Vials, RTU Vials)), Vial stoppers (By Type (RTS/RFS Vial Stoppers, RTU Vial Stoppers)), Cartridge, Cell Therapy Fill Finish Bags and other consumables), Instruments (By System Type (Integrated Systems, Standalone Systems), By Machine Type (Automated Machines, Semi-Automated & Manual Machines), End User (Contract Manufacturing Organization (CMOs), Pharmaceutical & Biopharmaceutical Companies and Other end users) and by Region (North America, Europe, Asia Pacific, Latin America, Middle East, and Africa).

The scope of the report covers detailed information regarding the major factors, such as drivers, restraints, challenges, and opportunities, influencing the growth of the fill finish manufacturing market. A detailed analysis of the key industry players has been done to provide insights into their business overview, products, solutions, key strategies, collaborations, partnerships, and agreements. New approvals/launches, collaborations, acquisitions, and recent developments associated with the fill finish manufacturing market.

Key Benefits of Buying the Report:

The report will help market leaders and new entrants by providing them with the closest approximations of the revenue numbers for the overall fill finish manufacturing market and its subsegments. It will also help stakeholders better understand the competitive landscape and gain more insights to better position their businesses and make suitable go-to-market strategies. This report will enable stakeholders to understand the market's pulse and provide them with information on the key market drivers, restraints, opportunities, and challenges.

The report provides insights on the following pointers:

- Analysis of key drivers (GLP-1, biosimilars and vaccines pipeline expansion driving volumes for biologics fill finish, Annex-1 compliance requirements driving equipment upgradation, increasing demand for automated & small-batch solutions to cater to personalized medicine manufacturing, outsourcing to fill finish CDMOs to drive capacity expansions) restraints (High CAPEX requirements for isolators & robotic aseptic lines to deter adoption, skilled labor shortage in sterile operations due to high CDMO staffing.), opportunities (Demand for cell & gene therapy/ mRNA small batch manufacturing, onshoring/ nearshoring for North America & Europe and integration of predictive analytics.), and challenges (Need for sustainable & PFAS-free consumables for fill finish) influencing the growth of the market.

- Service Development/Innovation: Detailed insights on upcoming technologies, research & development activities in the fill finish manufacturing market

- Market Development: Comprehensive information about lucrative markets - the report analyzes the market across varied regions

- Market Diversification: Exhaustive information about untapped geographies, recent developments, and investments in the fill finish manufacturing market

- Competitive Assessment: In-depth assessment of market shares, growth strategies, and product offerings of leading players. A detailed analysis of the key industry players has been done to provide insights into their key strategies, product launches/ approvals, acquisitions, partnerships, agreements, collaborations, other recent developments, investment and funding activities, brand/product comparative analysis, and vendor valuation and financial metrics of the fill finish manufacturing market.

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 STUDY OBJECTIVES

- 1.2 MARKET DEFINITION

- 1.3 INCLUSIONS AND EXCLUSIONS

- 1.4 STUDY SCOPE

- 1.4.1 SEGMENTS CONSIDERED

- 1.4.2 YEARS CONSIDERED

- 1.4.3 CURRENCY CONSIDERED

- 1.5 STAKEHOLDERS

- 1.6 SUMMARY OF CHANGES

2 RESEARCH METHODOLOGY

- 2.1 RESEARCH DATA

- 2.1.1 SECONDARY DATA

- 2.1.1.1 Objectives of secondary research

- 2.1.1.2 Key data from secondary sources

- 2.1.2 PRIMARY DATA

- 2.1.2.1 Breakdown of primaries (supply- and demand-side participants)

- 2.1.2.2 Key objective of primary research

- 2.1.1 SECONDARY DATA

- 2.2 MARKET ESTIMATION

- 2.2.1 GLOBAL MARKET ESTIMATION

- 2.2.1.1 Company revenue analysis (bottom-up approach)

- 2.2.1.1.1 Revenue share analysis of BD& Co.

- 2.2.1.2 MnM repository analysis

- 2.2.1.3 Primary interviews

- 2.2.1.1 Company revenue analysis (bottom-up approach)

- 2.2.2 INSIGHTS OF PRIMARY EXPERTS

- 2.2.3 SEGMENTAL MARKET SIZE ESTIMATION (TOP-DOWN APPROACH)

- 2.2.1 GLOBAL MARKET ESTIMATION

- 2.3 MARKET GROWTH RATE PROJECTIONS

- 2.4 DATA TRIANGULATION

- 2.5 RESEARCH ASSUMPTIONS

- 2.6 RESEARCH LIMITATIONS

- 2.7 RISK ANALYSIS

3 EXECUTIVE SUMMARY

- 3.1 STRATEGIC IMPERATIVES FOR KEY STAKEHOLDERS

- 3.1.1 FILL FINISH CONSUMABLE MANUFACTURERS

- 3.1.1.1 Shift to RTU & COP containers

- 3.1.1.2 Annex-1 compliance support for customers

- 3.1.1.3 PFAS-free, PPWR-ready portfolio to become table-stakes for customers

- 3.1.2 FILL FINISH EQUIPMENT MANUFACTURERS

- 3.1.2.1 Shift to robotic processes with nested RTU vials, PFS, and cartridges

- 3.1.2.2 Integration of predictive maintenance

- 3.1.3 FILL FINISH CDMOS

- 3.1.3.1 Biologics play vs. growth in niche segments of CGT, ADC, and radiopharma

- 3.1.3.2 Integration of predictive maintenance

- 3.1.1 FILL FINISH CONSUMABLE MANUFACTURERS

4 PREMIUM INSIGHTS

- 4.1 ATTRACTIVE OPPORTUNITIES FOR PLAYERS IN FILL FINISH MANUFACTURING MARKET

- 4.2 EUROPE: FILL FINISH MANUFACTURING MARKET, BY PRODUCT AND COUNTRY (2025)

- 4.3 FILL FINISH MANUFACTURING MARKET, BY PRODUCT

- 4.4 FILL FINISH MANUFACTURING MARKET: GEOGRAPHIC GROWTH OPPORTUNITIES

5 MARKET OVERVIEW

- 5.1 INTRODUCTION

- 5.2 MARKET DYNAMICS

- 5.2.1 DRIVERS

- 5.2.1.1 GLP-1, biosimilars, and vaccines pipeline expansion driving volumes for biologics fill-finish

- 5.2.1.2 Annex-1 compliance requirements driving equipment upgradation

- 5.2.1.3 Increasing demand for automated & small-batch solutions to cater to personalized medicine manufacturing

- 5.2.1.4 Outsourcing to fill-finish CDMOs driving capacity expansions

- 5.2.2 RESTRAINTS

- 5.2.2.1 High CAPEX requirements for isolators & robotic aseptic lines to deter adoption

- 5.2.2.2 Skilled labor shortage in sterile operations due to high CDMO staffing

- 5.2.3 OPPORTUNITIES

- 5.2.3.1 Demand for cell & gene therapy/mRNA small-batch manufacturing

- 5.2.3.2 Onshoring/Nearshoring for North America and Europe

- 5.2.3.3 Integration of predictive analytics

- 5.2.4 CHALLENGES

- 5.2.4.1 Need for sustainable & PFAS-free consumables for fill finish

- 5.2.1 DRIVERS

- 5.3 TECHNOLOGY ANALYSIS

- 5.3.1 KEY TECHNOLOGIES

- 5.3.1.1 Aseptic processing

- 5.3.1.2 Sterilization

- 5.3.2 COMPLIMENTARY TECHNOLOGIES

- 5.3.2.1 Automation and robotics

- 5.3.2.2 Isolator technology

- 5.3.3 ADJACENT TECHNOLOGIES

- 5.3.3.1 Single use systems

- 5.3.3.2 Inspection and quality control

- 5.3.1 KEY TECHNOLOGIES

- 5.4 TRENDS/DISRUPTIONS IMPACTING CUSTOMERS' BUSINESSES

- 5.4.1 KEY LAUNCHES AND PIPELINE OF BIOSIMILARS, GLP-1, CGT, ADC & RADIOPHARMACEUTICALS

- 5.4.2 US FDA APPROVAL TREND OF DRUG APPROVALS BY DOSAGE FORM

- 5.4.2.1 Injectable vs. other dosage forms

- 5.4.2.2 Subcutaneous vs. intramuscular biologics

- 5.5 FILL FINISH OUTSOURCING TRENDS

- 5.6 PRICING ANALYSIS

- 5.6.1 AVERAGE SELLING PRICE TREND, BY REGION

- 5.6.2 INDICATIVE PRICING ANALYSIS, BY PRODUCT

- 5.7 VALUE CHAIN ANALYSIS

- 5.8 SUPPLY CHAIN ANALYSIS

- 5.9 ECOSYSTEM ANALYSIS

- 5.9.1 CONSUMABLES

- 5.9.2 INSTRUMENTS

- 5.9.3 END USERS

- 5.9.4 MANUFACTURING SITES, EXPANSIONS, AND CAPEX TRENDS OF KEY FILL FINISH CDMOS, 2022-2025

- 5.10 PATENT ANALYSIS

- 5.10.1 NUMBER OF PATENTS FILED, BY DOCUMENT TYPE, 2014-2024

- 5.10.2 LIST OF KEY PATENTS, 2023-2024

- 5.11 REGULATORY ANALYSIS

- 5.11.1 REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- 5.11.2 REGULATORY FRAMEWORK

- 5.11.2.1 North America

- 5.11.2.1.1 US

- 5.11.2.1.2 Canada

- 5.11.2.2 Europe

- 5.11.2.2.1 Germany

- 5.11.2.2.2 France

- 5.11.2.2.3 UK

- 5.11.2.3 Asia Pacific

- 5.11.2.3.1 China

- 5.11.2.3.2 Japan

- 5.11.2.3.3 India

- 5.11.2.4 Rest of the World

- 5.11.2.4.1 Brazil

- 5.11.2.4.2 Argentina

- 5.11.2.4.3 Saudi Arabia

- 5.11.2.1 North America

- 5.12 KEY CONFERENCES & EVENTS, 2025-2026

- 5.13 PORTER'S FIVE FORCES ANALYSIS

- 5.13.1 THREAT OF NEW ENTRANTS

- 5.13.2 THREAT OF SUBSTITUTES

- 5.13.3 BARGAINING POWER OF SUPPLIERS

- 5.13.4 BARGAINING POWER OF BUYERS

- 5.13.5 INTENSITY OF COMPETITIVE RIVALRY

- 5.14 KEY STAKEHOLDERS & BUYING CRITERIA

- 5.14.1 KEY STAKEHOLDERS IN BUYING PROCESS

- 5.14.2 KEY BUYING CRITERIA

- 5.14.2.1 Key unmet needs of end users

- 5.14.2.1.1 Truly flexible, multi-format lines

- 5.14.2.1.2 Low-MOQ custom packs for clinical CGT

- 5.14.2.1 Key unmet needs of end users

- 5.15 INVESTMENT & FUNDING SCENARIO

- 5.16 IMPACT OF AI/GEN AI ON FILL FINISH MANUFACTURING MARKET

- 5.17 TRADE DATA ANALYSIS

- 5.17.1 GLASS AMPOULES

- 5.17.2 ARTICLES FOR CONVEYANCE OR PACKAGING OF PLASTIC GOODS, STOPPERS, LIDS, CAPS, AND OTHER CLOSURES

- 5.17.3 LABORATORY, HYGIENIC, OR PHARMACEUTICAL GLASSWARE, WHETHER OR NOT GRADUATED OR CALIBRATED

- 5.17.4 HYGIENIC OR PHARMACEUTICAL ARTICLES, INCLUDING TEATS OF VULCANIZED RUBBER (EXCL. HARD RUBBER), WITH OR WITHOUT FITTINGS OF HARD RUBBER

- 5.18 TRUMP TARIFF IMPACT ON FILL FINISH MANUFACTURING MARKET

- 5.18.1 KEY TARIFF RATES

- 5.18.2 PRICE IMPACT ANALYSIS

- 5.18.3 KEY IMPACT ON VARIOUS REGIONS

- 5.18.3.1 US

- 5.18.3.2 Europe

- 5.18.3.3 Asia Pacific

- 5.18.3.4 Rest of the World

- 5.18.4 END-USE INDUSTRY IMPACT

- 5.18.4.1 Contract manufacturing organizations

- 5.18.4.2 Pharmaceutical & biopharmaceutical companies

- 5.18.4.3 Other end users

6 FILL FINISH MANUFACTURING MARKET, BY PRODUCT

- 6.1 INTRODUCTION

- 6.2 CONSUMABLES

- 6.2.1 PREFILLABLE SYRINGES

- 6.2.1.1 Rising need for high-quality drug delivery systems to boost market

- 6.2.1.2 Prefillable syringes, by component

- 6.2.1.2.1 Prefillable syringe systems and components

- 6.2.1.3 Plunger stoppers

- 6.2.1.3.1 Rising prevalence of chronic diseases to positively impact pre-fillable syringes plunger stopper growth

- 6.2.1.4 Prefillable syringes, by material

- 6.2.1.4.1 Glass pre filled syringes

- 6.2.1.4.2 Polymer prefilled syringes

- 6.2.2 VIALS

- 6.2.2.1 Increased vaccination and treatment applications to drive growth

- 6.2.2.2 Vials, by material

- 6.2.2.2.1 Glass vials

- 6.2.2.2.2 Polymer vials

- 6.2.2.3 Vials, by format

- 6.2.2.3.1 Bulk vials

- 6.2.2.3.2 RTU vials

- 6.2.3 VIAL STOPPERS

- 6.2.3.1 Vial stoppers, by type

- 6.2.3.1.1 RTS/RFS vial stoppers

- 6.2.3.1.2 RTU vials stopper

- 6.2.3.1 Vial stoppers, by type

- 6.2.4 CARTRIDGES

- 6.2.4.1 Rising cases of diabetes and autoimmune disorders to drive growth of cartridges

- 6.2.5 CELL THERAPY FILL FINISH BAGS

- 6.2.5.1 Specialized fill-finish bags enable safe and sterile cell therapy delivery

- 6.2.6 OTHER CONSUMABLES

- 6.2.1 PREFILLABLE SYRINGES

- 6.3 INSTRUMENTS

- 6.3.1 INSTRUMENTS, BY SYSTEM TYPE

- 6.3.1.1 Rise in applications to drive market growth

- 6.3.1.2 Integrated systems

- 6.3.1.2.1 Higher product yield and automation to drive market growth

- 6.3.1.3 Standalone systems

- 6.3.1.3.1 Customization-a key factor driving growth

- 6.3.2 INSTRUMENTS, BY MACHINE TYPE

- 6.3.2.1 Increased technological advancements to drive growth of machines market

- 6.3.2.2 Automated machines

- 6.3.2.2.1 Technological advancements attributed to market growth

- 6.3.2.3 Semi-automated and manual machines

- 6.3.2.3.1 Popularity of benchtop equipment to drive market growth

- 6.3.3 FILL FINISH CDMO SERVICES MARKET

- 6.3.1 INSTRUMENTS, BY SYSTEM TYPE

7 FILL FINISH MANUFACTURING MARKET, BY END USER

- 7.1 INTRODUCTION

- 7.2 CONTRACT MANUFACTURING ORGANIZATIONS (CMOS)

- 7.2.1 GROWING PACE OF OUTSOURCING TO BENEFIT CMO SECTOR

- 7.3 PHARMACEUTICAL AND BIOPHARMACEUTICAL COMPANIES

- 7.3.1 INVESTMENTS IN NEW BIOLOGICS PRODUCTION FACILITIES TO DRIVE MARKET

- 7.4 OTHERS

8 FILL FINISH MANUFACTURING MARKET, BY REGION

- 8.1 INTRODUCTION

- 8.2 NORTH AMERICA

- 8.2.1 NORTH AMERICA: MACROECONOMIC ANALYSIS

- 8.2.2 US

- 8.2.2.1 Rising number of pipeline products for fill finish manufacturing to drive market

- 8.2.3 CANADA

- 8.2.3.1 Competitive business environment to boost market

- 8.3 EUROPE

- 8.3.1 EUROPE: MACROECONOMIC ANALYSIS

- 8.3.2 GERMANY

- 8.3.2.1 Rising focus on clinical research and patent approvals to drive market

- 8.3.3 UK

- 8.3.3.1 Growth in biopharmaceutical industry to support market growth

- 8.3.4 FRANCE

- 8.3.4.1 Increasing focus on developing biologics to drive demand for fill-finish technologies

- 8.3.5 ITALY

- 8.3.5.1 Investments and advancements to drive market

- 8.3.6 SPAIN

- 8.3.6.1 Innovations in fill finish manufacturing market to drive growth

- 8.3.7 SWITZERLAND

- 8.3.7.1 Outsourcing trends and collaboration with contract manufacturing organizations to drive growth

- 8.3.8 REST OF EUROPE

- 8.4 ASIA PACIFIC

- 8.4.1 ASIA PACIFIC: MACROECONOMIC ANALYSIS

- 8.4.2 CHINA

- 8.4.2.1 Increased investments in biologics and biosimilar drug research to drive market

- 8.4.3 JAPAN

- 8.4.3.1 Rise in aging population to drive demand for medications

- 8.4.4 INDIA

- 8.4.4.1 Large domestic consumption and export of generic drugs to drive market

- 8.4.5 SOUTH KOREA

- 8.4.5.1 Well-developed healthcare industry and presence of major pharmaceutical manufacturers to drive market

- 8.4.6 REST OF ASIA PACIFIC

- 8.5 LATIN AMERICA

- 8.5.1 LATIN AMERICA: MACROECONOMIC ANALYSIS

- 8.5.2 BRAZIL

- 8.5.2.1 Free and universal healthcare services to boost market

- 8.5.3 MEXICO

- 8.5.3.1 Government initiatives in healthcare industry to fuel demand for pharmaceutical products

- 8.5.4 REST OF LATIN AMERICA

- 8.6 MIDDLE EAST

- 8.6.1 MIDDLE EAST: MACROECONOMIC ANALYSIS

- 8.6.2 GCC COUNTRIES

- 8.6.2.1 Saudi Arabia (KSA)

- 8.6.2.1.1 More comprehensive access to healthcare services to fuel demand for pharmaceuticals

- 8.6.2.2 United Arab Emirates (UAE)

- 8.6.2.2.1 Increasing initiatives for domestic pharmaceutical production to drive market

- 8.6.2.3 Rest of GCC

- 8.6.2.1 Saudi Arabia (KSA)

- 8.6.3 REST OF MIDDLE EAST

- 8.7 AFRICA

- 8.7.1 GROWING COLLABORATIONS TO SUPPORT GROWTH

9 COMPETITIVE LANDSCAPE

- 9.1 OVERVIEW

- 9.2 OVERVIEW OF STRATEGIES ADOPTED BY KEY PLAYERS IN FILL FINISH MANUFACTURING MARKET, 2022-2024

- 9.3 REVENUE ANALYSIS, 2022-2024

- 9.4 MARKET SHARE ANALYSIS, 2024

- 9.5 COMPANY EVALUATION MATRIX: KEY PLAYERS, 2024

- 9.5.1 STARS

- 9.5.2 EMERGING LEADERS

- 9.5.3 PERVASIVE PLAYERS

- 9.5.4 PARTICIPANTS

- 9.5.5 COMPETITIVE BENCHMARKING OF TOP PLAYERS

- 9.5.6 COMPANY FOOTPRINT

- 9.5.6.1 Region footprint

- 9.5.6.2 Product footprint

- 9.5.6.3 End user footprint

- 9.6 COMPANY EVALUATION MATRIX: STARTUPS/SMES, 2024

- 9.6.1 PROGRESSIVE COMPANIES

- 9.6.2 RESPONSIVE COMPANIES

- 9.6.3 DYNAMIC COMPANIES

- 9.6.4 STARTING BLOCKS

- 9.6.5 COMPETITIVE BENCHMARKING: STARTUPS/SMES, 2024

- 9.7 VALUATION AND FINANCIAL METRICS OF FILL FINISH MANUFACTURING MARKET VENDORS

- 9.7.1 FINANCIAL METRICS

- 9.7.2 COMPANY VALUATION

- 9.8 BRAND/PRODUCT COMPARISON

- 9.9 COMPETITIVE SCENARIO

- 9.9.1 PRODUCT APPROVALS

- 9.9.2 DEALS

- 9.9.3 EXPANSIONS

10 COMPANY PROFILES

- 10.1 KEY PLAYERS

- 10.1.1 SYNTEGON TECHNOLOGY GMBH

- 10.1.1.1 Business overview

- 10.1.1.2 Products/Services/Solutions offered

- 10.1.1.3 Recent developments

- 10.1.1.3.1 Product launches and approvals

- 10.1.1.3.2 Deals

- 10.1.1.3.3 Expansions

- 10.1.1.3.4 Other developments

- 10.1.1.4 MnM view

- 10.1.1.4.1 Key strengths

- 10.1.1.4.2 Strategic choices

- 10.1.1.4.3 Weaknesses & competitive threats

- 10.1.2 I.M.A. S.P.A.

- 10.1.2.1 Business overview

- 10.1.2.2 Products/Services/Solutions offered

- 10.1.2.3 Recent developments

- 10.1.2.3.1 Deals

- 10.1.2.4 MnM view

- 10.1.2.4.1 Key strengths/Right to win

- 10.1.2.4.2 Strategic choices

- 10.1.2.4.3 Weaknesses & competitive threats

- 10.1.3 BD & CO

- 10.1.3.1 Business overview

- 10.1.3.2 Products/Services/Solutions offered

- 10.1.3.3 Recent developments

- 10.1.3.3.1 Product launches and approvals

- 10.1.3.3.2 Deals

- 10.1.3.3.3 Expansions

- 10.1.3.4 MnM view

- 10.1.3.4.1 Key strengths/Right to win

- 10.1.3.4.2 Strategic choices

- 10.1.3.4.3 Weaknesses & competitive threats

- 10.1.4 WEST PHARMACEUTICAL SERVICES, INC.

- 10.1.4.1 Business overview

- 10.1.4.2 Products/Services/Solutions offered

- 10.1.4.3 Recent developments

- 10.1.4.3.1 Product launches and approvals

- 10.1.4.3.2 Deals

- 10.1.4.3.3 Expansions

- 10.1.4.4 MnM view

- 10.1.4.4.1 Key strengths/Right to win

- 10.1.4.4.2 Strategic choices

- 10.1.4.4.3 Weaknesses & competitive threats

- 10.1.5 GERRESHEIMER AG

- 10.1.5.1 Business overview

- 10.1.5.2 Products/Services/Solutions offered

- 10.1.5.3 Recent developments

- 10.1.5.3.1 Product launches and approvals

- 10.1.5.3.2 Deals

- 10.1.5.3.3 Expansions

- 10.1.5.4 MnM view

- 10.1.5.4.1 Key strengths/Right to win

- 10.1.5.4.2 Strategic choices

- 10.1.5.4.3 Weaknesses & competitive threats

- 10.1.6 APTARGROUP, INC.

- 10.1.6.1 Business overview

- 10.1.6.2 Products/Services/Solutions offered

- 10.1.6.3 Recent developments

- 10.1.6.3.1 Product launches and approvals

- 10.1.6.3.2 Deals

- 10.1.6.3.3 Expansions

- 10.1.7 DATWYLER HOLDING INC.

- 10.1.7.1 Business overview

- 10.1.7.2 Products/Services/Solutions offered

- 10.1.7.3 Recent developments

- 10.1.7.3.1 Product launches and approvals

- 10.1.7.3.2 Deals

- 10.1.7.3.3 Expansions

- 10.1.8 DANAHER CORPORATION

- 10.1.8.1 Business overview

- 10.1.8.2 Products/Services/Solutions offered

- 10.1.8.3 Recent developments

- 10.1.8.3.1 Deals

- 10.1.9 STEVANATO GROUP S.P.A.

- 10.1.9.1 Business overview

- 10.1.9.2 Products/Services/Solutions offered

- 10.1.9.3 Recent developments

- 10.1.9.3.1 Product launches and approvals

- 10.1.9.3.2 Deals

- 10.1.9.3.3 Expansions

- 10.1.10 OPTIMA

- 10.1.10.1 Business overview

- 10.1.10.2 Products/Services/Solutions offered

- 10.1.10.3 Recent developments

- 10.1.10.3.1 Deals

- 10.1.10.3.2 Expansions

- 10.1.11 BAUSCH+STROBEL

- 10.1.11.1 Business overview

- 10.1.11.2 Products/Services/Solutions offered

- 10.1.11.3 Recent developments

- 10.1.11.3.1 Product launches and approvals

- 10.1.12 GRONINGER & CO. GMBH

- 10.1.12.1 Business overview

- 10.1.12.2 Products/Services/Solutions offered

- 10.1.12.3 Recent developments

- 10.1.12.3.1 Expansions

- 10.1.13 SGD PHARMA

- 10.1.13.1 Business overview

- 10.1.13.2 Products/Services/Solutions offered

- 10.1.13.3 Recent developments

- 10.1.13.3.1 Product launches and approvals

- 10.1.13.3.2 Deals

- 10.1.13.3.3 Expansions

- 10.1.14 SCHOTT

- 10.1.14.1 Business overview

- 10.1.14.2 Products/Services/Solutions offered

- 10.1.14.3 Recent developments

- 10.1.14.3.1 Product launches and approvals

- 10.1.14.3.2 Deals

- 10.1.14.3.3 Expansions

- 10.1.14.3.4 Other developments

- 10.1.15 NIPRO CORPORATION

- 10.1.15.1 Business overview

- 10.1.15.2 Products/Services/Solutions offered

- 10.1.15.3 Recent developments

- 10.1.15.3.1 Product launches and approvals

- 10.1.15.3.2 Expansions

- 10.1.16 BAUSCH ADVANCED TECHNOLOGY GROUP

- 10.1.16.1 Business overview

- 10.1.16.2 Products/Services/Solutions offered

- 10.1.17 MAQUINARIA INDUSTRIAL DARA, SL

- 10.1.17.1 Business overview

- 10.1.17.2 Products/Services/Solutions offered

- 10.1.17.3 Recent developments

- 10.1.17.3.1 Product launches and approvals

- 10.1.17.3.2 Deals

- 10.1.1 SYNTEGON TECHNOLOGY GMBH

- 10.2 OTHER PLAYERS

- 10.2.1 STERILINE S.R.L.

- 10.2.2 AUTOMATED SYSTEMS OF TACOMA, LLC

- 10.2.3 SIO2 MATERIALS SCIENCE

- 10.2.4 WEILER ENGINEERING, INC.

- 10.2.5 FEDEGARI AUTOCLAVI S.P.A.

- 10.2.6 SHANDONG PHARMACEUTICAL GLASS

- 10.2.7 MITSUBISHI GAS CHEMICAL

- 10.2.8 TERUMO CORPORATION

- 10.2.9 SKAN AG

- 10.2.10 ATS LIFE SCIENCE SYSTEMS

- 10.2.11 CORNING INC.

- 10.2.12 CREDENCE MEDSYSTEMS

- 10.2.13 3P INNOVATION LTD.

- 10.2.14 COLANAR AG.

11 APPENDIX

- 11.1 DISCUSSION GUIDE

- 11.2 KNOWLEDGESTORE: MARKETSANDMARKETS' SUBSCRIPTION PORTAL

- 11.3 CUSTOMIZATION OPTIONS

- 11.4 RELATED REPORTS

- 11.5 AUTHOR DETAILS

List of Tables

- TABLE 1 FILL FINISH MANUFACTURING MARKET: INCLUSIONS AND EXCLUSIONS

- TABLE 2 IMPACT ANALYSIS OF SUPPLY-SIDE AND DEMAND-SIDE FACTORS

- TABLE 3 FILL FINISH MANUFACTURING MARKET: RISK ANALYSIS

- TABLE 4 FILL FINISH MANUFACTURING MARKET: IMPACT ANALYSIS

- TABLE 5 KEY LAUNCHES OF BIOSIMILARS (2022-2025)

- TABLE 6 PIPELINE OF BIOSIMILARS (PHASE 3) (2022-2025)

- TABLE 7 KEY LAUNCHES OF GLP1 (2022-2025)

- TABLE 8 PIPELINE OF GLP-1 (2022-2025)

- TABLE 9 KEY LAUNCHES OF CGT (2022-2025)

- TABLE 10 PIPELINE OF CGT (2022-2025)

- TABLE 11 KEY LAUNCHES OF ADC (2022-2025)

- TABLE 12 PIPELINE OF ADC (2022-2025)

- TABLE 13 KEY LAUNCHES OF RADIOPHARMACEUTICALS (2022-2025)

- TABLE 14 PIPELINE OF RADIOPHARMACEUTICALS (2022-2025)

- TABLE 15 US FDA APPROVALS FOR INJECTABLES (2022-2024)

- TABLE 16 US FDA APPROVALS FOR OTHER DOSAGE FORMS (2022-2024)

- TABLE 17 US FDA APPROVALS FOR SUBCUTANEOUS BIOLOGICS (2022-2024)

- TABLE 18 US FDA APPROVALS FOR INTRAMUSCULAR BIOLOGICS (2022-2024)

- TABLE 19 AVERAGE SELLING PRICE OF FILL FINISH MANUFACTURING PRODUCTS, BY REGION

- TABLE 20 INDICATIVE PRICING ANALYSIS IN FILL FINISH MANUFACTURING MARKET, BY PRODUCT

- TABLE 21 ROLE OF CONSUMABLES IN FILL FINISH MANUFACTURING MARKET

- TABLE 22 ROLE OF INSTRUMENTS IN FILL FINISH MANUFACTURING MARKET

- TABLE 23 ROLE OF END USERS IN FILL FINISHING MANUFACTURING MARKET

- TABLE 24 MANUFACTURING SITES OF KEY CONSUMABLES/ EQUIPMENT SUPPLIERS

- TABLE 25 KEY MANUFACTURING EXPANSIONS FOR EQUIPMENT & CONSUMABLES SUPPLIERS 2023-2025

- TABLE 26 CAPEX FOR PUBLICLY LISTED KEY CONSUMABLES/ EQUIPMENT SUPPLIERS 2021- 2024 (IN USD MILLION)

- TABLE 27 FILL FINISH MANUFACTURING SITES FOR KEY CDMOS

- TABLE 28 EXPANSIONS FOR FILL FINISH MANUFACTURING (2023-2025) BY CDMOS

- TABLE 29 CAPEX FOR SELECTED PUBLICLY LISTED KEY FILL FINISH CDMOS, 2021-2024 (IN USD MILLION)

- TABLE 30 FILL FINISH MANUFACTURING MARKET: NUMBER OF PATENTS FILED, 2014-2024

- TABLE 31 DETAILED ANALYSIS OF KEY PATENTS IN FILL FINISH MANUFACTURING MARKET

- TABLE 32 NORTH AMERICA: REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- TABLE 33 EUROPE: REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- TABLE 34 ASIA PACIFIC: REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- TABLE 35 REST OF THE WORLD: REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- TABLE 36 FILL FINISH MANUFACTURING MARKET: LIST OF KEY CONFERENCES & EVENTS, JANUARY 2025-DECEMBER 2026

- TABLE 37 FILL FINISH MANUFACTURING MARKET: PORTER'S FIVE FORCES

- TABLE 38 INFLUENCE OF KEY STAKEHOLDERS ON BUYING PROCESS, BY PRODUCT TYPE

- TABLE 39 KEY BUYING CRITERIA FOR CONSUMABLES FOR TOP THREE END USERS

- TABLE 40 KEY BUYING CRITERIA FOR INSTRUMENTS FOR TOP THREE END USERS

- TABLE 41 IMPORT VALUE FOR GLASS AMPOULES, 2020-2024 (USD)

- TABLE 42 EXPORT VALUE FOR GLASS AMPOULES, 2020-2024 (USD)

- TABLE 43 IMPORT VOLUME FOR GLASS AMPOULES, 2020-2024 (TONS/UNITS)

- TABLE 44 EXPORT VOLUME FOR GLASS AMPOULES, 2020-2024 (TONS/UNITS)

- TABLE 45 IMPORT VALUE FOR ARTICLES FOR CONVEYANCE OR PACKAGING OF PLASTIC GOODS, STOPPERS, LIDS, CAPS, AND OTHER CLOSURES, 2020-2024 (USD)

- TABLE 46 EXPORT VALUE FOR ARTICLES FOR CONVEYANCE OR PACKAGING OF PLASTIC GOODS, STOPPERS, LIDS, CAPS, AND OTHER CLOSURES, 2020-2024 (USD)

- TABLE 47 IMPORT VOLUME FOR ARTICLES FOR CONVEYANCE OR PACKAGING OF PLASTIC GOODS, STOPPERS, LIDS, CAPS, AND OTHER CLOSURES, 2020-2024 (TONS)

- TABLE 48 EXPORT VOLUME FOR ARTICLES FOR CONVEYANCE OR PACKAGING OF PLASTIC GOODS, STOPPERS, LIDS, CAPS, AND OTHER CLOSURES, 2020-2024 (TONS)

- TABLE 49 IMPORT VALUE FOR ARTICLES FOR LABORATORY, HYGIENIC, OR PHARMACEUTICAL GLASSWARE, WHETHER OR NOT GRADUATED OR CALIBRATED, 2020-2024 (USD)

- TABLE 50 EXPORT VALUE FOR LABORATORY, HYGIENIC, OR PHARMACEUTICAL GLASSWARE, WHETHER OR NOT GRADUATED OR CALIBRATED, 2020-2024 (USD)

- TABLE 51 IMPORT VOLUME FOR LABORATORY, HYGIENIC, OR PHARMACEUTICAL GLASSWARE, WHETHER OR NOT GRADUATED OR CALIBRATED, 2020-2024 (TONS/UNITS)

- TABLE 52 EXPORT VOLUME FOR LABORATORY, HYGIENIC, OR PHARMACEUTICAL GLASSWARE, WHETHER OR NOT GRADUATED OR CALIBRATED, 2020-2024 (TONS)

- TABLE 53 IMPORT VALUE FOR HYGIENIC OR PHARMACEUTICAL ARTICLES (INCLUDING TEATS OF VULCANIZED RUBBER), 2020-2024 (USD)

- TABLE 54 EXPORT VALUE FOR HYGIENIC OR PHARMACEUTICAL ARTICLES (INCLUDING TEATS OF VULCANIZED RUBBER), 2020-2024 (USD)

- TABLE 55 IMPORT VOLUME FOR HYGIENIC OR PHARMACEUTICAL ARTICLES (INCLUDING TEATS OF VULCANIZED RUBBER), 2020-2024 (TONS/UNITS)

- TABLE 56 EXPORT VOLUME FOR HYGIENIC OR PHARMACEUTICAL ARTICLES (INCLUDING TEATS OF VULCANIZED RUBBER), 2020-2024 (TONS)

- TABLE 57 US-ADJUSTED RECIPROCAL TARIFF RATES

- TABLE 58 KEY PRODUCT-RELATED TARIFF: FILL FINISH MANUFACTURING COMPONENTS

- TABLE 59 CRITICAL COMPONENTS EXPOSED TO TARIFF CHANGES

- TABLE 60 FILL FINISH MANUFACTURING MARKET, BY PRODUCT, 2023-2030 (USD MILLION)

- TABLE 61 FILL FINISH MANUFACTURING CONSUMABLES MARKET, BY TYPE, 2023-2030 (USD MILLION)

- TABLE 62 FILL FINISH MANUFACTURING MARKET FOR CONSUMABLES, BY TYPE, 2023-2030 (BILLION UNITS)

- TABLE 63 FILL FINISH MANUFACTURING CONSUMABLES MARKET, BY REGION, 2023-2030 (USD MILLION)

- TABLE 64 NORTH AMERICA: FILL FINISH MANUFACTURING CONSUMABLES MARKET, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 65 EUROPE: FILL FINISH MANUFACTURING CONSUMABLES MARKET, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 66 ASIA PACIFIC: FILL FINISH MANUFACTURING CONSUMABLES MARKET, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 67 LATIN AMERICA: FILL FINISH MANUFACTURING CONSUMABLES MARKET, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 68 MIDDLE EAST: FILL FINISH MANUFACTURING CONSUMABLES MARKET, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 69 GCC: FILL FINISH MANUFACTURING CONSUMABLES MARKET, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 70 PREFILLABLE SYRINGES FILL FINISH MANUFACTURING MARKET, BY REGION, 2023-2030 (USD MILLION)

- TABLE 71 NORTH AMERICA: PREFILLABLE SYRINGES FILL FINISH MANUFACTURING MARKET, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 72 EUROPE: PREFILLABLE SYRINGES FILL FINISH MANUFACTURING MARKET, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 73 ASIA PACIFIC: PREFILLABLE SYRINGES FILL FINISH MANUFACTURING MARKET, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 74 LATIN AMERICA: PREFILLABLE SYRINGES FILL FINISH MANUFACTURING MARKET, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 75 MIDDLE EAST: PREFILLABLE SYRINGES FILL FINISH MANUFACTURING MARKET, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 76 GCC: PREFILLABLE SYRINGES FILL FINISH MANUFACTURING MARKET, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 77 FILL FINISH MANUFACTURING MARKET FOR PREFILLABLE SYRINGES, BY COMPONENT, 2023-2030 (USD MILLION)

- TABLE 78 FILL FINISH MANUFACTURING MARKET FOR PREFILLABLE SYRINGES SYSTEMS AND COMPONENTS, BY REGION, 2023-2030 (USD MILLION)

- TABLE 79 NORTH AMERICA: FILL FINISH MANUFACTURING MARKET FOR PREFILLABLE SYRINGES SYSTEMS AND COMPONENTS, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 80 EUROPE: FILL FINISH MANUFACTURING MARKET FOR PREFILLABLE SYRINGES SYSTEMS AND COMPONENTS, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 81 ASIA PACIFIC: FILL FINISH MANUFACTURING MARKET FOR PREFILLABLE SYRINGES SYSTEMS AND COMPONENTS, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 82 LATIN AMERICA: FILL FINISH MANUFACTURING MARKET FOR PREFILLABLE SYRINGES SYSTEMS AND COMPONENTS, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 83 MIDDLE EAST: FILL FINISH MANUFACTURING MARKET FOR PREFILLABLE SYRINGES SYSTEMS AND COMPONENTS, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 84 GCC: FILL FINISH MANUFACTURING MARKET FOR PREFILLABLE SYRINGES SYSTEMS AND COMPONENTS, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 85 FILL FINISH MANUFACTURING MARKET FOR PLUNGER STOPPERS, BY REGION, 2023-2030 (USD MILLION)

- TABLE 86 NORTH AMERICA: FILL FINISH MANUFACTURING MARKET FOR PLUNGER STOPPERS, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 87 EUROPE: FILL FINISH MANUFACTURING MARKET FOR PLUNGER STOPPERS, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 88 ASIA PACIFIC: FILL FINISH MANUFACTURING MARKET FOR PLUNGER STOPPERS, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 89 LATIN AMERICA: FILL FINISH MANUFACTURING MARKET FOR PLUNGER STOPPERS, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 90 MIDDLE EAST: FILL FINISH MANUFACTURING MARKET FOR PLUNGER STOPPERS, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 91 GCC: FILL FINISH MANUFACTURING MARKET FOR PLUNGER STOPPERS, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 92 FILL FINISH MANUFACTURING MARKET FOR PREFILLABLE SYRINGES, BY MATERIAL, 2023-2030 (USD MILLION)

- TABLE 93 GLASS PREFILLABLE SYRINGES FILL FINISH MANUFACTURING MARKET, BY REGION, 2023-2030 (USD MILLION)

- TABLE 94 NORTH AMERICA: GLASS PREFILLABLE SYRINGES FILL FINISH MANUFACTURING MARKET, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 95 EUROPE: GLASS PREFILLABLE SYRINGES FILL FINISH MANUFACTURING MARKET, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 96 ASIA PACIFIC: GLASS PREFILLABLE SYRINGES FILL FINISH MANUFACTURING MARKET, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 97 LATIN AMERICA: GLASS PREFILLABLE SYRINGES FILL FINISH MANUFACTURING MARKET, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 98 MIDDLE EAST: GLASS PREFILLABLE SYRINGES FILL FINISH MANUFACTURING MARKET, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 99 GCC COUNTRIES: GLASS PREFILLABLE SYRINGES FILL FINISH MANUFACTURING MARKET, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 100 FILL FINISH MANUFACTURING MARKET FOR POLYMER PREFILLED SYRINGES, BY REGION, 2023-2030 (USD MILLION)

- TABLE 101 NORTH AMERICA: FILL FINISH MANUFACTURING MARKET FOR POLYMER PREFILLED SYRINGES, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 102 EUROPE: FILL FINISH MANUFACTURING MARKET FOR POLYMER PREFILLED SYRINGES, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 103 ASIA PACIFIC: FILL FINISH MANUFACTURING MARKET FOR POLYMER PREFILLED SYRINGES, BY COUNTRY 2023-2030 (USD MILLION)

- TABLE 104 LATIN AMERICA: FILL FINISH MANUFACTURING MARKET POLYMER PREFILLED SYRINGES, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 105 MIDDLE EAST: FILL FINISH MANUFACTURING MARKET FOR POLYMER PREFILLED SYRINGES, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 106 GCC COUNTRIES: POLYMER PREFILLABLE SYRINGES FILL FINISH MANUFACTURING MARKET, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 107 VIALS FILL FINISH MANUFACTURING MARKET, BY REGION, 2023-2030 (USD MILLION)

- TABLE 108 NORTH AMERICA: VIALS FILL FINISH MANUFACTURING MARKET, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 109 EUROPE: VIALS FILL FINISH MANUFACTURING MARKET, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 110 ASIA PACIFIC: VIALS FILL FINISH MANUFACTURING MARKET, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 111 LATIN AMERICA: VIALS FILL FINISH MANUFACTURING MARKET, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 112 MIDDLE EAST: VIALS FILL FINISH MANUFACTURING MARKET, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 113 GCC COUNTRIES: VIALS FILL FINISH MANUFACTURING MARKET, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 114 FILL FINISH MANUFACTURING MARKET FOR VIALS, BY MATERIAL, 2023-2030 (USD MILLION)

- TABLE 115 FILL FINISH MANUFACTURING MARKET FOR GLASS VIALS, BY REGION, 2023-2030 (USD MILLION)

- TABLE 116 NORTH AMERICA: FILL FINISH MANUFACTURING MARKET FOR GLASS VIALS, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 117 EUROPE: FILL FINISH MANUFACTURING MARKET FOR GLASS VIALS, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 118 ASIA PACIFIC: FILL FINISH MANUFACTURING MARKET FOR GLASS VIALS, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 119 LATIN AMERICA: FILL FINISH MANUFACTURING MARKET FOR GLASS VIALS, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 120 MIDDLE EAST: FILL FINISH MANUFACTURING MARKET FOR GLASS VIALS, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 121 GCC COUNTRIES: FILL FINISH MANUFACTURING MARKET FOR GLASS VIAL, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 122 FILL FINISH MANUFACTURING MARKET FOR POLYMER VIALS, BY REGION, 2023-2030 (USD MILLION)

- TABLE 123 NORTH AMERICA: FILL FINISH MANUFACTURING MARKET FOR POLYMER VIALS, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 124 EUROPE: FILL FINISH MANUFACTURING MARKET FOR POLYMER VIALS, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 125 ASIA PACIFIC: FILL FINISH MANUFACTURING MARKET FOR POLYMER VIALS, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 126 LATIN AMERICA: FILL FINISH MANUFACTURING MARKET FOR POLYMER VIALS, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 127 MIDDLE EAST: FILL FINISH MANUFACTURING MARKET FOR POLYMER VIALS, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 128 GCC COUNTRIES: FILL FINISH MANUFACTURING MARKET FOR POLYMER VIAL, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 129 VIALS FILL FINISH MANUFACTURING MARKET, BY FORMAT, 2023-2030 (USD MILLION)

- TABLE 130 FILL FINISH MANUFACTURING MARKET FOR BULK VIALS, BY REGION, 2023-2030 (USD MILLION)

- TABLE 131 FILL FINISH MANUFACTURING MARKET FOR RTU VIALS, BY REGION, 2023-2030 (USD MILLION)

- TABLE 132 VIAL STOPPERS FILL FINISH MANUFACTURING MARKET, BY REGION, 2023-2030 (USD MILLION)

- TABLE 133 NORTH AMERICA: VIAL STOPPERS FILL FINISH MANUFACTURING MARKET, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 134 EUROPE: VIAL STOPPERS FILL FINISH MANUFACTURING MARKET, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 135 ASIA PACIFIC: VIAL STOPPERS FILL FINISH MANUFACTURING MARKET, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 136 LATIN AMERICA: VIAL STOPPERS FILL FINISH MANUFACTURING MARKET, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 137 MIDDLE EAST: VIAL STOPPERS FILL FINISH MANUFACTURING MARKET, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 138 GCC: VIAL STOPPERS FILL FINISH MANUFACTURING MARKET, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 139 FILL FINISH MANUFACTURING MARKET FOR VIAL STOPPERS, BY TYPE, 2023-2030 (USD MILLION)

- TABLE 140 FILL FINISH MANUFACTURING MARKET FOR RTS/ RFS VIAL STOPPERS, BY REGION, 2023-2030 (USD MILLION)

- TABLE 141 NORTH AMERICA: FILL FINISH MANUFACTURING MARKET FOR RTS/ RFS VIAL STOPPERS, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 142 EUROPE: FILL FINISH MANUFACTURING MARKET FOR RTS/ RFS VIAL STOPPERS, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 143 ASIA PACIFIC: FILL FINISH MANUFACTURING MARKET FOR RTS/ RFS VIAL STOPPERS, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 144 LATIN AMERICA: FILL FINISH MANUFACTURING MARKET FOR RTS/ RFS VIAL STOPPERS, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 145 MIDDLE EAST: FILL FINISH MANUFACTURING MARKET FOR RTS/ RFS VIAL STOPPERS, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 146 GCC COUNTRIES: FILL FINISH MANUFACTURING MARKET FOR RTS/ RFS VIAL STOPPERS, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 147 FILL FINISH MANUFACTURING MARKET FOR RTU VIALS STOPPER, BY REGION, 2023-2030 (USD MILLION)

- TABLE 148 NORTH AMERICA: FILL FINISH MANUFACTURING MARKET FOR RTU VIALS STOPPER, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 149 EUROPE: FILL FINISH MANUFACTURING MARKET FOR RTU VIALS STOPPER, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 150 ASIA PACIFIC: FILL FINISH MANUFACTURING MARKET FOR RTU VIALS STOPPER, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 151 LATIN AMERICA: FILL FINISH MANUFACTURING MARKET FOR RTU VIALS STOPPER, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 152 MIDDLE EAST: FILL FINISH MANUFACTURING MARKET FOR RTU VIALS STOPPER, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 153 GCC COUNTRIES: FILL FINISH MANUFACTURING MARKET FOR RTU VIALS STOPPER, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 154 CARTRIDGES FILL FINISH MANUFACTURING MARKET, BY REGION, 2023-2030 (USD MILLION)

- TABLE 155 NORTH AMERICA: CARTRIDGES FILL FINISH MANUFACTURING MARKET, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 156 EUROPE: CARTRIDGES FILL FINISH MANUFACTURING MARKET, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 157 ASIA PACIFIC: CARTRIDGES FILL FINISH MANUFACTURING MARKET, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 158 LATIN AMERICA: CARTRIDGES FILL FINISH MANUFACTURING MARKET, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 159 MIDDLE EAST: CARTRIDGES FILL FINISH MANUFACTURING MARKET, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 160 GCC COUNTRIES: CARTRIDGES FILL FINISH MANUFACTURING MARKET, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 161 FILL FINISH MANUFACTURING MARKET FOR CELL THERAPY FILL FINISH BAGS, BY REGION, 2023-2030 (USD MILLION)

- TABLE 162 NORTH AMERICA: FILL FINISH MANUFACTURING MARKET FOR CELL THERAPY FILL FINISH BAGS, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 163 EUROPE: FILL FINISH MANUFACTURING MARKET FOR CELL THERAPY FILL FINISH BAGS, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 164 ASIA PACIFIC: FILL FINISH MANUFACTURING MARKET FOR CELL THERAPY FILL FINISH BAGS, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 165 LATIN AMERICA: FILL FINISH MANUFACTURING MARKET FOR CELL THERAPY FILL FINISH BAGS, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 166 MIDDLE EAST: FILL FINISH MANUFACTURING MARKET FOR CELL THERAPY FILL FINISH BAGS, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 167 GCC COUNTRIES: FILL FINISH MANUFACTURING MARKET FOR CELL THERAPY FILL FINISH BAGS, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 168 OTHER CONSUMABLE FILL FINISH MANUFACTURING MARKET, BY REGION, 2023-2030 (USD MILLION)

- TABLE 169 NORTH AMERICA: OTHER CONSUMABLE FILL FINISH MANUFACTURING MARKET, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 170 EUROPE: OTHER CONSUMABLE FILL FINISH MANUFACTURING MARKET, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 171 ASIA PACIFIC: OTHER CONSUMABLE FILL FINISH MANUFACTURING MARKET, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 172 LATIN AMERICA: OTHER CONSUMABLE FILL FINISH MANUFACTURING MARKET, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 173 MIDDLE EAST: OTHER CONSUMABLE FILL FINISH MANUFACTURING MARKET, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 174 GCC COUNTRIES: OTHER CONSUMABLE FILL FINISH MANUFACTURING MARKET, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 175 FILL FINISH MANUFACTURING MARKET FOR INSTRUMENTS, BY SYSTEM TYPE, 2023-2030 (USD MILLION)

- TABLE 176 FILL FINISH MANUFACTURING MARKET FOR INTEGRATED SYSTEMS, BY REGION, 2023-2030 (USD MILLION)

- TABLE 177 NORTH AMERICA: FILL FINISH MANUFACTURING MARKET FOR INTEGRATED SYSTEMS, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 178 EUROPE: FILL FINISH MANUFACTURING MARKET FOR INTEGRATED SYSTEMS, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 179 ASIA PACIFIC: FILL FINISH MANUFACTURING MARKET FOR INTEGRATED SYSTEMS, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 180 LATIN AMERICA: FILL FINISH MANUFACTURING MARKET FOR INTEGRATED SYSTEMS, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 181 MIDDLE EAST: FILL FINISH MANUFACTURING MARKET FOR INTEGRATED SYSTEMS, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 182 GCC COUNTRIES: FILL FINISH MANUFACTURING MARKET FOR INTEGRATED SYSTEMS, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 183 FILL FINISH MANUFACTURING MARKET FOR STANDALONE SYSTEMS, BY REGION, 2023-2030 (USD MILLION)

- TABLE 184 NORTH AMERICA: FILL FINISH MANUFACTURING MARKET FOR STANDALONE SYSTEMS, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 185 EUROPE: FILL FINISH MANUFACTURING MARKET FOR STANDALONE SYSTEMS, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 186 ASIA PACIFIC: FILL FINISH MANUFACTURING MARKET FOR STANDALONE SYSTEMS, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 187 LATIN AMERICA: FILL FINISH MANUFACTURING MARKET FOR STANDALONE SYSTEMS, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 188 MIDDLE EAST: FILL FINISH MANUFACTURING MARKET FOR STANDALONE SYSTEMS, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 189 GCC COUNTRIES: FILL FINISH MANUFACTURING MARKET FOR STANDALONE SYSTEMS, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 190 FILL FINISH MANUFACTURING MARKET FOR INSTRUMENTS, BY MACHINE TYPE, 2023-2030 (USD MILLION)

- TABLE 191 FILL FINISH MANUFACTURING MARKET FOR INSTRUMENTS, BY INSTRUMENT, 2023-2030 (NUMBER OF UNITS)

- TABLE 192 FILL FINISH MANUFACTURING MARKET FOR AUTOMATED MACHINES, BY REGION, 2023-2030 (USD MILLION)

- TABLE 193 NORTH AMERICA: FILL FINISH MANUFACTURING MARKET FOR AUTOMATED MACHINES, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 194 EUROPE: FILL FINISH MANUFACTURING MARKET FOR AUTOMATED MACHINES, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 195 ASIA PACIFIC: FILL FINISH MANUFACTURING MARKET FOR AUTOMATED MACHINES, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 196 LATIN AMERICA: FILL FINISH MANUFACTURING MARKET FOR AUTOMATED MACHINES, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 197 MIDDLE EAST: FILL FINISH MANUFACTURING MARKET FOR AUTOMATED MACHINES, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 198 GCC COUNTRIES: FILL FINISH MANUFACTURING MARKET FOR AUTOMATED MACHINES, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 199 FILL FINISH MANUFACTURING MARKET FOR SEMI-AUTOMATED AND MANUAL MACHINES, BY REGION, 2023-2030 (USD MILLION)

- TABLE 200 NORTH AMERICA: FILL FINISH MANUFACTURING MARKET FOR SEMI-AUTOMATED AND MANUAL MACHINES, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 201 EUROPE: FILL FINISH MANUFACTURING MARKET FOR SEMI-AUTOMATED AND MANUAL MACHINES, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 202 ASIA PACIFIC: FILL FINISH MANUFACTURING MARKET FOR SEMI-AUTOMATED AND MANUAL MACHINES, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 203 LATIN AMERICA: FILL FINISH MANUFACTURING MARKET FOR SEMI-AUTOMATED AND MANUAL MACHINES, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 204 MIDDLE EAST: FILL FINISH MANUFACTURING MARKET FOR SEMI-AUTOMATED AND MANUAL MACHINES, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 205 GCC COUNTRIES: FILL FINISH MANUFACTURING MARKET FOR SEMI-AUTOMATED AND MANUAL MACHINES, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 206 FILL FINISH MANUFACTURING MARKET FOR CDMOS SERVICES, BY REGION, 2023-2030 (USD MILLION)

- TABLE 207 NORTH AMERICA: FILL FINISH MANUFACTURING MARKET FOR CDMOS SERVICES, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 208 EUROPE: FILL FINISH MANUFACTURING MARKET FOR CDMOS SERVICES, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 209 ASIA PACIFIC: FILL FINISH MANUFACTURING MARKET FOR CDMOS SERVICES, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 210 LATIN AMERICA: FILL FINISH MANUFACTURING MARKET FOR CDMOS SERVICES, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 211 MIDDLE EAST: FILL FINISH MANUFACTURING MARKET FOR CDMOS SERVICES, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 212 GCC COUNTRIES: FILL FINISH MANUFACTURING MARKET FOR CDMOS SERVICES, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 213 FILL FINISH MANUFACTURING MARKET, BY END USER, 2023-2030 (USD MILLION)

- TABLE 214 FILL FINISH MANUFACTURING MARKET FOR CONTRACT MANUFACTURING ORGANIZATIONS (CMOS), BY REGION, 2023-2030 (USD MILLION)

- TABLE 215 NORTH AMERICA: FILL FINISH MANUFACTURING MARKET FOR CONTRACT MANUFACTURING ORGANIZATIONS (CMOS), BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 216 EUROPE: FILL FINISH MANUFACTURING MARKET FOR CONTRACT MANUFACTURING ORGANIZATIONS (CMOS), BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 217 ASIA PACIFIC: FILL FINISH MANUFACTURING MARKET FOR CONTRACT MANUFACTURING ORGANIZATIONS (CMOS), BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 218 LATIN AMERICA: FILL FINISH MANUFACTURING MARKET FOR CONTRACT MANUFACTURING ORGANIZATIONS (CMOS), BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 219 MIDDLE EAST: FILL FINISH MANUFACTURING MARKET FOR CONTRACT MANUFACTURING ORGANIZATIONS (CMOS), BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 220 GCC COUNTRIES: FILL FINISH MANUFACTURING MARKET FOR CONTRACT MANUFACTURING ORGANIZATIONS (CMOS), BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 221 FILL FINISH MANUFACTURING MARKET FOR PHARMACEUTICAL AND BIOPHARMACEUTICAL COMPANIES, BY REGION, 2023-2030 (USD MILLION)

- TABLE 222 NORTH AMERICA: FILL FINISH MANUFACTURING MARKET FOR PHARMACEUTICAL AND BIOPHARMACEUTICAL COMPANIES, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 223 EUROPE: FILL FINISH MANUFACTURING MARKET FOR PHARMACEUTICAL AND BIOPHARMACEUTICAL COMPANIES, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 224 ASIA PACIFIC: FILL FINISH MANUFACTURING MARKET FOR PHARMACEUTICAL AND BIOPHARMACEUTICAL COMPANIES, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 225 LATIN AMERICA: FILL FINISH MANUFACTURING MARKET FOR PHARMACEUTICAL AND BIOPHARMACEUTICAL COMPANIES, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 226 MIDDLE EAST: FILL FINISH MANUFACTURING MARKET FOR PHARMACEUTICAL AND BIOPHARMACEUTICAL COMPANIES, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 227 GCC COUNTRIES: FILL FINISH MANUFACTURING MARKET FOR PHARMACEUTICAL AND BIOPHARMACEUTICAL COMPANIES, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 228 FILL FINISH MANUFACTURING MARKET FOR OTHERS, BY REGION, 2023-2030 (USD MILLION)

- TABLE 229 NORTH AMERICA: FILL FINISH MANUFACTURING MARKET FOR OTHERS, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 230 EUROPE: FILL FINISH MANUFACTURING MARKET FOR OTHERS, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 231 ASIA PACIFIC: FILL FINISH MANUFACTURING MARKET FOR OTHERS, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 232 LATIN AMERICA: FILL FINISH MANUFACTURING MARKET FOR OTHERS, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 233 MIDDLE EAST: FILL FINISH MANUFACTURING MARKET FOR OTHERS, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 234 GCC COUNTRIES: FILL FINISH MANUFACTURING MARKET FOR OTHERS, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 235 FILL FINISH MANUFACTURING MARKET, BY REGION, 2023-2030 (USD MILLION)

- TABLE 236 NORTH AMERICA: KEY MACRO INDICATORS

- TABLE 237 NORTH AMERICA: FILL FINISH MANUFACTURING MARKET, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 238 NORTH AMERICA: FILL FINISH MANUFACTURING MARKET, BY PRODUCT, 2023-2030 (USD MILLION)

- TABLE 239 NORTH AMERICA: FILL FINISH MANUFACTURING MARKET FOR CONSUMABLES, BY TYPE, 2023-2030 (USD MILLION)

- TABLE 240 NORTH AMERICA: FILL FINISH MANUFACTURING MARKET FOR PRE-FILLABLE SYRINGES, BY COMPONENT, 2023-2030 (USD MILLION)

- TABLE 241 NORTH AMERICA: FILL FINISH MANUFACTURING MARKET FOR PRE-FILLABLE SYRINGES, BY MATERIAL, 2023-2030 (USD MILLION)

- TABLE 242 NORTH AMERICA: FILL FINISH MANUFACTURING MARKET FOR VIALS, BY MATERIAL, 2023-2030 (USD MILLION)

- TABLE 243 NORTH AMERICA: FILL FINISH MANUFACTURING MARKET FOR VIALS, BY FORMAT, 2023-2030 (USD MILLION)

- TABLE 244 NORTH AMERICA: FILL FINISH MANUFACTURING MARKET FOR VIAL STOPPERS, BY TYPE, 2023-2030 (USD MILLION)

- TABLE 245 NORTH AMERICA: FILL FINISH MANUFACTURING MARKET FOR INSTRUMENTS, BY SYSTEM TYPE, 2023-2030 (USD MILLION)

- TABLE 246 NORTH AMERICA: FILL FINISH MANUFACTURING MARKET FOR INSTRUMENTS, BY MACHINE TYPE, 2023-2030 (USD MILLION)

- TABLE 247 NORTH AMERICA: FILL FINISH MANUFACTURING MARKET, BY END USER, 2023-2030 (USD MILLION)

- TABLE 248 US: FILL FINISH MANUFACTURING MARKET, BY PRODUCT, 2023-2030 (USD MILLION)

- TABLE 249 US: FILL FINISH MANUFACTURING MARKET FOR CONSUMABLES, BY TYPE, 2023-2030 (USD MILLION)

- TABLE 250 US: FILL FINISH MANUFACTURING MARKET FOR PRE-FILLABLE SYRINGES, BY COMPONENT, 2023-2030 (USD MILLION)

- TABLE 251 US: FILL FINISH MANUFACTURING MARKET FOR PRE-FILLABLE SYRINGES, BY MATERIAL, 2023-2030 (USD MILLION)

- TABLE 252 US: FILL FINISH MANUFACTURING MARKET FOR VIALS, BY MATERIAL, 2023-2030 (USD MILLION)

- TABLE 253 US: FILL FINISH MANUFACTURING MARKET FOR VIAL STOPPERS, BY TYPE, 2023-2030 (USD MILLION)

- TABLE 254 US: FILL FINISH MANUFACTURING MARKET FOR INSTRUMENTS, BY SYSTEM TYPE, 2023-2030 (USD MILLION)

- TABLE 255 US: FILL FINISH MANUFACTURING MARKET FOR INSTRUMENTS, BY MACHINE TYPE, 2023-2030 (USD MILLION)

- TABLE 256 US: FILL FINISH MANUFACTURING MARKET, BY END USER, 2023-2030 (USD MILLION)

- TABLE 257 CANADA: FILL FINISH MANUFACTURING MARKET, BY PRODUCT, 2023-2030 (USD MILLION)

- TABLE 258 CANADA: FILL FINISH MANUFACTURING MARKET FOR CONSUMABLES, BY TYPE, 2023-2030 (USD MILLION)

- TABLE 259 CANADA: FILL FINISH MANUFACTURING MARKET FOR PRE-FILLABLE SYRINGES, BY COMPONENT, 2023-2030 (USD MILLION)

- TABLE 260 CANADA: FILL FINISH MANUFACTURING MARKET FOR PREFILLED SYRINGES, BY MATERIAL, 2023-2030 (USD MILLION)

- TABLE 261 CANADA: FILL FINISH MANUFACTURING MARKET FOR VIALS, BY MATERIAL, 2023-2030 (USD MILLION)

- TABLE 262 CANADA: FILL FINISH MANUFACTURING MARKET FOR VIAL STOPPERS, BY TYPE, 2023-2030 (USD MILLION)

- TABLE 263 CANADA: FILL FINISH MANUFACTURING MARKET FOR INSTRUMENTS, BY SYSTEM TYPE, 2023-2030 (USD MILLION)

- TABLE 264 CANADA: FILL FINISH MANUFACTURING MARKET FOR INSTRUMENTS, BY MACHINE TYPE, 2023-2030 (USD MILLION)

- TABLE 265 CANADA: FILL FINISH MANUFACTURING MARKET, BY END USER, 2023-2030 (USD MILLION)

- TABLE 266 EUROPE: KEY MACRO INDICATORS

- TABLE 267 EUROPE: FILL FINISH MANUFACTURING MARKET, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 268 EUROPE: FILL FINISH MANUFACTURING MARKET, BY PRODUCT, 2023-2030 (USD MILLION)

- TABLE 269 EUROPE: FILL FINISH MANUFACTURING MARKET FOR CONSUMABLES, BY TYPE, 2023-2030 (USD MILLION)

- TABLE 270 EUROPE: FILL FINISH MANUFACTURING MARKET FOR PRE-FILLABLE SYRINGES, BY COMPONENT, 2023-2030 (USD MILLION)

- TABLE 271 EUROPE: FILL FINISH MANUFACTURING MARKET FOR PREFILLED SYRINGES, BY MATERIAL, 2023-2030 (USD MILLION)

- TABLE 272 EUROPE: FILL FINISH MANUFACTURING MARKET FOR VIALS, BY MATERIAL, 2023-2030 (USD MILLION)

- TABLE 273 EUROPE: FILL FINISH MANUFACTURING MARKET FOR VIALS, BY FORMAT, 2023-2030 (USD MILLION)

- TABLE 274 EUROPE: FILL FINISH MANUFACTURING MARKET FOR VIAL STOPPERS, BY TYPE, 2023-2030 (USD MILLION)

- TABLE 275 EUROPE: FILL FINISH MANUFACTURING MARKET FOR INSTRUMENTS, BY SYSTEM TYPE, 2023-2030 (USD MILLION)

- TABLE 276 EUROPE: FILL FINISH MANUFACTURING MARKET FOR INSTRUMENTS, BY MACHINE TYPE, 2023-2030 (USD MILLION)

- TABLE 277 EUROPE: FILL FINISH MANUFACTURING MARKET, BY END USER, 2023-2030 (USD MILLION)

- TABLE 278 GERMANY: FILL FINISH MANUFACTURING MARKET, BY PRODUCT, 2023-2030 (USD MILLION)

- TABLE 279 GERMANY: FILL FINISH MANUFACTURING MARKET FOR CONSUMABLES, BY TYPE, 2023-2030 (USD MILLION)

- TABLE 280 GERMANY: FILL FINISH MANUFACTURING MARKET FOR PRE-FILLABLE SYRINGES, BY COMPONENT, 2023-2030 (USD MILLION)

- TABLE 281 GERMANY: FILL FINISH MANUFACTURING MARKET FOR PREFILLED SYRINGES, BY MATERIAL, 2023-2030 (USD MILLION)

- TABLE 282 GERMANY: FILL FINISH MANUFACTURING MARKET FOR VIALS, BY MATERIAL, 2023-2030 (USD MILLION)

- TABLE 283 GERMANY: FILL FINISH MANUFACTURING MARKET FOR VIAL STOPPERS, BY TYPE, 2023-2030 (USD MILLION)

- TABLE 284 GERMANY: FILL FINISH MANUFACTURING MARKET FOR INSTRUMENTS, BY SYSTEM TYPE, 2023-2030 (USD MILLION)

- TABLE 285 GERMANY: FILL FINISH MANUFACTURING MARKET FOR INSTRUMENTS, BY MACHINE TYPE, 2023-2030 (USD MILLION)

- TABLE 286 GERMANY: FILL FINISH MANUFACTURING MARKET, BY END USER, 2023-2030 (USD MILLION)

- TABLE 287 UK: FILL FINISH MANUFACTURING MARKET, BY PRODUCT, 2023-2030 (USD MILLION)

- TABLE 288 UK: FILL FINISH MANUFACTURING MARKET FOR CONSUMABLES, BY TYPE, 2023-2030 (USD MILLION)

- TABLE 289 UK: FILL FINISH MANUFACTURING MARKET FOR PRE-FILLABLE SYRINGES, BY COMPONENT, 2023-2030 (USD MILLION)

- TABLE 290 UK: FILL FINISH MANUFACTURING MARKET FOR PREFILLED SYRINGES, BY MATERIAL, 2023-2030 (USD MILLION)

- TABLE 291 UK: FILL FINISH MANUFACTURING MARKET FOR VIALS, BY MATERIAL, 2023-2030 (USD MILLION)

- TABLE 292 UK: FILL FINISH MANUFACTURING MARKET FOR VIAL STOPPERS, BY TYPE, 2023-2030 (USD MILLION)

- TABLE 293 UK: FILL FINISH MANUFACTURING MARKET FOR INSTRUMENTS, BY SYSTEM TYPE, 2023-2030 (USD MILLION)

- TABLE 294 UK: FILL FINISH MANUFACTURING MARKET FOR INSTRUMENTS, BY MACHINE TYPE, 2023-2030 (USD MILLION)

- TABLE 295 UK: FILL FINISH MANUFACTURING MARKET, BY END USER, 2023-2030 (USD MILLION)

- TABLE 296 FRANCE: FILL FINISH MANUFACTURING MARKET, BY PRODUCT, 2023-2030 (USD MILLION)

- TABLE 297 FRANCE: FILL FINISH MANUFACTURING MARKET FOR CONSUMABLES, BY TYPE, 2023-2030 (USD MILLION)

- TABLE 298 FRANCE: FILL FINISH MANUFACTURING MARKET FOR PRE-FILLABLE SYRINGES, BY COMPONENT, 2023-2030 (USD MILLION)

- TABLE 299 FRANCE: FILL FINISH MANUFACTURING MARKET FOR PREFILLED SYRINGES, BY MATERIAL, 2023-2030 (USD MILLION)

- TABLE 300 FRANCE: FILL FINISH MANUFACTURING MARKET FOR VIALS, BY MATERIAL, 2023-2030 (USD MILLION)

- TABLE 301 FRANCE: FILL FINISH MANUFACTURING MARKET FOR VIAL STOPPERS, BY TYPE, 2023-2030 (USD MILLION)

- TABLE 302 FRANCE: FILL FINISH MANUFACTURING MARKET FOR INSTRUMENTS, BY SYSTEM TYPE, 2023-2030 (USD MILLION)

- TABLE 303 FRANCE: FILL FINISH MANUFACTURING MARKET FOR INSTRUMENTS, BY MACHINE TYPE, 2023-2030 (USD MILLION)

- TABLE 304 FRANCE: FILL FINISH MANUFACTURING MARKET, BY END USER, 2023-2030 (USD MILLION)

- TABLE 305 ITALY: FILL FINISH MANUFACTURING MARKET, BY PRODUCT, 2023-2030 (USD MILLION)

- TABLE 306 ITALY: FILL FINISH MANUFACTURING MARKET FOR CONSUMABLES, BY TYPE, 2023-2030 (USD MILLION)

- TABLE 307 ITALY: FILL FINISH MANUFACTURING MARKET FOR PRE-FILLABLE SYRINGES, BY COMPONENT, 2023-2030 (USD MILLION)

- TABLE 308 ITALY: FILL FINISH MANUFACTURING MARKET FOR PREFILLED SYRINGES, BY MATERIAL, 2023-2030 (USD MILLION)

- TABLE 309 ITALY: FILL FINISH MANUFACTURING MARKET FOR VIALS, BY MATERIAL, 2023-2030 (USD MILLION)

- TABLE 310 ITALY: FILL FINISH MANUFACTURING MARKET FOR VIAL STOPPERS, BY TYPE, 2023-2030 (USD MILLION)

- TABLE 311 ITALY: FILL FINISH MANUFACTURING MARKET FOR INSTRUMENTS, BY SYSTEM TYPE, 2023-2030 (USD MILLION)

- TABLE 312 ITALY: FILL FINISH MANUFACTURING MARKET FOR INSTRUMENTS, BY MACHINE TYPE, 2023-2030 (USD MILLION)

- TABLE 313 ITALY: FILL FINISH MANUFACTURING MARKET, BY END USER, 2023-2030 (USD MILLION)

- TABLE 314 SPAIN: FILL FINISH MANUFACTURING MARKET, BY PRODUCT, 2023-2030 (USD MILLION)

- TABLE 315 SPAIN: FILL FINISH MANUFACTURING MARKET FOR CONSUMABLES, BY TYPE, 2023-2030 (USD MILLION)

- TABLE 316 SPAIN: FILL FINISH MANUFACTURING MARKET FOR PRE-FILLABLE SYRINGES, BY COMPONENT, 2023-2030 (USD MILLION)

- TABLE 317 SPAIN: FILL FINISH MANUFACTURING MARKET FOR PREFILLED SYRINGES, BY MATERIAL, 2023-2030 (USD MILLION)

- TABLE 318 SPAIN: FILL FINISH MANUFACTURING MARKET FOR VIALS, BY MATERIAL, 2023-2030 (USD MILLION)

- TABLE 319 SPAIN: FILL FINISH MANUFACTURING MARKET FOR VIAL STOPPERS, BY TYPE, 2023-2030 (USD MILLION)

- TABLE 320 SPAIN: FILL FINISH MANUFACTURING MARKET FOR INSTRUMENTS, BY SYSTEM TYPE, 2023-2030 (USD MILLION)

- TABLE 321 SPAIN: FILL FINISH MANUFACTURING MARKET FOR INSTRUMENTS, BY MACHINE TYPE, 2023-2030 (USD MILLION)

- TABLE 322 SPAIN: FILL FINISH MANUFACTURING MARKET, BY END USER, 2023-2030 (USD MILLION)

- TABLE 323 SWITZERLAND: FILL FINISH MANUFACTURING MARKET, BY PRODUCT, 2023-2030 (USD MILLION)

- TABLE 324 SWITZERLAND: FILL FINISH MANUFACTURING MARKET FOR CONSUMABLES, BY TYPE, 2023-2030 (USD MILLION)

- TABLE 325 SWITZERLAND: FILL FINISH MANUFACTURING MARKET FOR PRE-FILLABLE SYRINGES, BY COMPONENT, 2023-2030 (USD MILLION)

- TABLE 326 SWITZERLAND: FILL FINISH MANUFACTURING MARKET FOR PREFILLED SYRINGES, BY MATERIAL, 2023-2030 (USD MILLION)

- TABLE 327 SWITZERLAND: FILL FINISH MANUFACTURING MARKET FOR VIALS, BY MATERIAL, 2023-2030 (USD MILLION)

- TABLE 328 SWITZERLAND: FILL FINISH MANUFACTURING MARKET FOR VIAL STOPPERS, BY TYPE, 2023-2030 (USD MILLION)

- TABLE 329 SWITZERLAND: FILL FINISH MANUFACTURING MARKET FOR INSTRUMENTS, BY SYSTEM TYPE, 2023-2030 (USD MILLION)

- TABLE 330 SWITZERLAND: FILL FINISH MANUFACTURING MARKET FOR INSTRUMENTS, BY MACHINE TYPE, 2023-2030 (USD MILLION)

- TABLE 331 SWITZERLAND: FILL FINISH MANUFACTURING MARKET, BY END USER, 2023-2030 (USD MILLION)

- TABLE 332 REST OF EUROPE: FILL FINISH MANUFACTURING MARKET, BY PRODUCT, 2023-2030 (USD MILLION)

- TABLE 333 REST OF EUROPE: FILL FINISH MANUFACTURING MARKET FOR CONSUMABLES, BY TYPE, 2023-2030 (USD MILLION)

- TABLE 334 REST OF EUROPE: FILL FINISH MANUFACTURING MARKET FOR PRE-FILLABLE SYRINGES, BY COMPONENT, 2023-2030 (USD MILLION)

- TABLE 335 REST OF EUROPE: FILL FINISH MANUFACTURING MARKET FOR PREFILLED SYRINGES, BY MATERIAL, 2023-2030 (USD MILLION)

- TABLE 336 REST OF EUROPE: FILL FINISH MANUFACTURING MARKET FOR VIALS, BY MATERIAL, 2023-2030 (USD MILLION)

- TABLE 337 REST OF EUROPE: FILL FINISH MANUFACTURING MARKET FOR VIAL STOPPERS, BY TYPE, 2023-2030 (USD MILLION)

- TABLE 338 REST OF EUROPE: FILL FINISH MANUFACTURING MARKET FOR INSTRUMENTS, BY SYSTEM TYPE, 2023-2030 (USD MILLION)

- TABLE 339 REST OF EUROPE: FILL FINISH MANUFACTURING MARKET FOR INSTRUMENTS, BY MACHINE TYPE, 2023-2030 (USD MILLION)

- TABLE 340 REST OF EUROPE: FILL FINISH MANUFACTURING MARKET, BY END USER, 2023-2030 (USD MILLION)

- TABLE 341 ASIA PACIFIC: KEY MACRO INDICATORS

- TABLE 342 ASIA PACIFIC: FILL FINISH MANUFACTURING MARKET, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 343 ASIA PACIFIC: FILL FINISH MANUFACTURING MARKET, BY PRODUCT, 2023-2030 (USD MILLION)

- TABLE 344 ASIA PACIFIC: FILL FINISH MANUFACTURING MARKET FOR CONSUMABLES, BY TYPE, 2023-2030 (USD MILLION)

- TABLE 345 ASIA PACIFIC: FILL FINISH MANUFACTURING MARKET FOR PRE-FILLABLE SYRINGES, BY COMPONENT, 2023-2030 (USD MILLION)

- TABLE 346 ASIA PACIFIC: FILL FINISH MANUFACTURING MARKET FOR PREFILLED SYRINGES, BY MATERIAL, 2023-2030 (USD MILLION)

- TABLE 347 ASIA PACIFIC: FILL FINISH MANUFACTURING MARKET FOR VIALS, BY MATERIAL, 2023-2030 (USD MILLION)

- TABLE 348 ASIA PACIFIC: FILL FINISH MANUFACTURING MARKET FOR VIALS, BY FORMAT, 2023-2030 (USD MILLION)

- TABLE 349 ASIA PACIFIC: FILL FINISH MANUFACTURING MARKET FOR VIAL STOPPERS, BY TYPE, 2023-2030 (USD MILLION)

- TABLE 350 ASIA PACIFIC: FILL FINISH MANUFACTURING MARKET FOR INSTRUMENTS, BY SYSTEM TYPE, 2023-2030 (USD MILLION)

- TABLE 351 ASIA PACIFIC: FILL FINISH MANUFACTURING MARKET FOR INSTRUMENTS, BY MACHINE TYPE, 2023-2030 (USD MILLION)

- TABLE 352 ASIA PACIFIC: FILL FINISH MANUFACTURING MARKET, BY END USER, 2023-2030 (USD MILLION)

- TABLE 353 CHINA: FILL FINISH MANUFACTURING MARKET, BY PRODUCT, 2023-2030 (USD MILLION)

- TABLE 354 CHINA: FILL FINISH MANUFACTURING MARKET FOR CONSUMABLES, BY TYPE, 2023-2030 (USD MILLION)

- TABLE 355 CHINA: FILL FINISH MANUFACTURING MARKET FOR PRE-FILLABLE SYRINGES, BY COMPONENT, 2023-2030 (USD MILLION)

- TABLE 356 CHINA: FILL FINISH MANUFACTURING MARKET FOR PREFILLED SYRINGES, BY MATERIAL, 2023-2030 (USD MILLION)

- TABLE 357 CHINA: FILL FINISH MANUFACTURING MARKET FOR VIALS, BY MATERIAL, 2023-2030 (USD MILLION)

- TABLE 358 CHINA: FILL FINISH MANUFACTURING MARKET FOR VIAL STOPPERS, BY TYPE, 2023-2030 (USD MILLION)

- TABLE 359 CHINA: FILL FINISH MANUFACTURING MARKET FOR INSTRUMENTS, BY SYSTEM TYPE, 2023-2030 (USD MILLION)

- TABLE 360 CHINA: FILL FINISH MANUFACTURING MARKET FOR INSTRUMENTS, BY MACHINE TYPE, 2023-2030 (USD MILLION)

- TABLE 361 CHINA: FILL FINISH MANUFACTURING MARKET, BY END USER, 2023-2030 (USD MILLION)

- TABLE 362 JAPAN: FILL FINISH MANUFACTURING MARKET, BY PRODUCT, 2023-2030 (USD MILLION)

- TABLE 363 JAPAN: FILL FINISH MANUFACTURING MARKET FOR CONSUMABLES, BY TYPE, 2023-2030 (USD MILLION)

- TABLE 364 JAPAN: FILL FINISH MANUFACTURING MARKET FOR PRE-FILLABLE SYRINGES, BY COMPONENT, 2023-2030 (USD MILLION)

- TABLE 365 JAPAN: FILL FINISH MANUFACTURING MARKET FOR PREFILLED SYRINGES, BY MATERIAL, 2023-2030 (USD MILLION)

- TABLE 366 JAPAN: FILL FINISH MANUFACTURING MARKET FOR VIALS, BY MATERIAL, 2023-2030 (USD MILLION)

- TABLE 367 JAPAN: FILL FINISH MANUFACTURING MARKET FOR VIAL STOPPERS, BY TYPE, 2023-2030 (USD MILLION)

- TABLE 368 JAPAN: FILL FINISH MANUFACTURING MARKET FOR INSTRUMENTS, BY SYSTEM TYPE, 2023-2030 (USD MILLION)

- TABLE 369 JAPAN: FILL FINISH MANUFACTURING MARKET FOR INSTRUMENTS, BY MACHINE TYPE, 2023-2030 (USD MILLION)

- TABLE 370 JAPAN: FILL FINISH MANUFACTURING MARKET, BY END USER, 2023-2030 (USD MILLION)

- TABLE 371 INDIA: FILL FINISH MANUFACTURING MARKET, BY PRODUCT, 2023-2030 (USD MILLION)

- TABLE 372 INDIA: FILL FINISH MANUFACTURING MARKET FOR CONSUMABLES, BY TYPE, 2023-2030 (USD MILLION)

- TABLE 373 INDIA: FILL FINISH MANUFACTURING MARKET FOR PRE-FILLABLE SYRINGES, BY COMPONENT, 2023-2030 (USD MILLION)

- TABLE 374 INDIA: FILL FINISH MANUFACTURING MARKET FOR PREFILLED SYRINGES, BY MATERIAL, 2023-2030 (USD MILLION)

- TABLE 375 INDIA: FILL FINISH MANUFACTURING MARKET FOR VIALS, BY MATERIAL, 2023-2030 (USD MILLION)

- TABLE 376 INDIA: FILL FINISH MANUFACTURING MARKET FOR VIAL STOPPERS, BY TYPE, 2023-2030 (USD MILLION)

- TABLE 377 INDIA: FILL FINISH MANUFACTURING MARKET FOR INSTRUMENTS, BY SYSTEM TYPE, 2023-2030 (USD MILLION)

- TABLE 378 INDIA: FILL FINISH MANUFACTURING MARKET FOR INSTRUMENTS, BY MACHINE TYPE, 2023-2030 (USD MILLION)

- TABLE 379 INDIA: FILL FINISH MANUFACTURING MARKET, BY END USER, 2023-2030 (USD MILLION)

- TABLE 380 SOUTH KOREA: FILL FINISH MANUFACTURING MARKET, BY PRODUCT, 2023-2030 (USD MILLION)

- TABLE 381 SOUTH KOREA: FILL FINISH MANUFACTURING MARKET FOR CONSUMABLES, BY TYPE, 2023-2030 (USD MILLION)

- TABLE 382 SOUTH KOREA: FILL FINISH MANUFACTURING MARKET FOR PRE-FILLABLE SYRINGES, BY COMPONENT, 2023-2030 (USD MILLION)

- TABLE 383 SOUTH KOREA: FILL FINISH MANUFACTURING MARKET FOR PREFILLED SYRINGES, BY MATERIAL, 2023-2030 (USD MILLION)

- TABLE 384 SOUTH KOREA: FILL FINISH MANUFACTURING MARKET FOR VIALS, BY MATERIAL, 2023-2030 (USD MILLION)

- TABLE 385 SOUTH KOREA: FILL FINISH MANUFACTURING MARKET FOR VIAL STOPPERS, BY TYPE, 2023-2030 (USD MILLION)

- TABLE 386 SOUTH KOREA: FILL FINISH MANUFACTURING MARKET FOR INSTRUMENTS, BY SYSTEM TYPE, 2023-2030 (USD MILLION)

- TABLE 387 SOUTH KOREA: FILL FINISH MANUFACTURING MARKET FOR INSTRUMENTS, BY MACHINE TYPE, 2023-2030 (USD MILLION)

- TABLE 388 SOUTH KOREA: FILL FINISH MANUFACTURING MARKET, BY END USER, 2023-2030 (USD MILLION)

- TABLE 389 REST OF ASIA PACIFIC: FILL FINISH MANUFACTURING MARKET, BY PRODUCT, 2023-2030 (USD MILLION)

- TABLE 390 REST OF ASIA PACIFIC: FILL FINISH MANUFACTURING MARKET FOR CONSUMABLES, BY TYPE, 2023-2030 (USD MILLION)

- TABLE 391 REST OF ASIA PACIFIC: FILL FINISH MANUFACTURING MARKET FOR PRE-FILLABLE COMPONENT, BY TYPE, 2023-2030 (USD MILLION)

- TABLE 392 REST OF ASIA PACIFIC: FILL FINISH MANUFACTURING MARKET FOR PREFILLED SYRINGES, BY MATERIAL, 2023-2030 (USD MILLION)

- TABLE 393 REST OF ASIA PACIFIC: FILL FINISH MANUFACTURING MARKET FOR VIALS, BY MATERIAL, 2023-2030 (USD MILLION)

- TABLE 394 REST OF ASIA PACIFIC: FILL FINISH MANUFACTURING MARKET FOR VIAL STOPPERS, BY TYPE, 2023-2030 (USD MILLION)

- TABLE 395 REST OF ASIA PACIFIC: FILL FINISH MANUFACTURING MARKET FOR INSTRUMENTS, BY SYSTEM TYPE, 2023-2030 (USD MILLION)

- TABLE 396 REST OF ASIA PACIFIC: FILL FINISH MANUFACTURING MARKET FOR INSTRUMENTS, BY MACHINE TYPE, 2023-2030 (USD MILLION)

- TABLE 397 REST OF ASIA PACIFIC: FILL FINISH MANUFACTURING MARKET, BY END USER, 2023-2030 (USD MILLION)

- TABLE 398 LATIN AMERICA: KEY MACRO INDICATORS

- TABLE 399 LATIN AMERICA: FILL FINISH MANUFACTURING MARKET, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 400 LATIN AMERICA: FILL FINISH MANUFACTURING MARKET, BY PRODUCT, 2023-2030 (USD MILLION)

- TABLE 401 LATIN AMERICA: FILL FINISH MANUFACTURING MARKET FOR CONSUMABLES, BY TYPE, 2023-2030 (USD MILLION)

- TABLE 402 LATIN AMERICA: FILL FINISH MANUFACTURING MARKET FOR PRE-FILLABLE SYRINGES, BY COMPONENT, 2023-2030 (USD MILLION)

- TABLE 403 LATIN AMERICA: FILL FINISH MANUFACTURING MARKET FOR PREFILLED SYRINGES, BY MATERIAL, 2023-2030 (USD MILLION)

- TABLE 404 LATIN AMERICA: FILL FINISH MANUFACTURING MARKET FOR VIALS, BY MATERIAL, 2023-2030 (USD MILLION)

- TABLE 405 LATIN AMERICA: FILL FINISH MANUFACTURING MARKET FOR VIALS, BY FORMAT, 2023-2030 (USD MILLION

- TABLE 406 LATIN AMERICA: FILL FINISH MANUFACTURING MARKET FOR VIAL STOPPERS, BY TYPE, 2023-2030 (USD MILLION)

- TABLE 407 LATIN AMERICA: FILL FINISH MANUFACTURING MARKET FOR INSTRUMENTS, BY SYSTEM TYPE, 2023-2030 (USD MILLION)

- TABLE 408 LATIN AMERICA: FILL FINISH MANUFACTURING MARKET FOR INSTRUMENTS, BY MACHINE TYPE, 2023-2030 (USD MILLION)

- TABLE 409 LATIN AMERICA: FILL FINISH MANUFACTURING MARKET, BY END USER, 2023-2030 (USD MILLION)

- TABLE 410 BRAZIL: FILL FINISH MANUFACTURING MARKET, BY PRODUCT, 2023-2030 (USD MILLION)

- TABLE 411 BRAZIL: FILL FINISH MANUFACTURING MARKET FOR CONSUMABLES, BY TYPE, 2023-2030 (USD MILLION)

- TABLE 412 BRAZIL: FILL FINISH MANUFACTURING MARKET FOR PRE-FILLABLE SYRINGES, BY COMPONENT, 2023-2030 (USD MILLION)

- TABLE 413 BRAZIL: FILL FINISH MANUFACTURING MARKET FOR PREFILLED SYRINGES, BY MATERIAL, 2023-2030 (USD MILLION)

- TABLE 414 BRAZIL: FILL FINISH MANUFACTURING MARKET FOR VIALS, BY MATERIAL, 2023-2030 (USD MILLION)

- TABLE 415 BRAZIL: FILL FINISH MANUFACTURING MARKET FOR VIAL STOPPERS, BY TYPE, 2023-2030 (USD MILLION)

- TABLE 416 BRAZIL: FILL FINISH MANUFACTURING MARKET FOR INSTRUMENTS, BY SYSTEM TYPE, 2023-2030 (USD MILLION)

- TABLE 417 BRAZIL: FILL FINISH MANUFACTURING MARKET FOR INSTRUMENTS, BY MACHINE TYPE, 2023-2030 (USD MILLION)

- TABLE 418 BRAZIL: FILL FINISH MANUFACTURING MARKET, BY END USER, 2023-2030 (USD MILLION)

- TABLE 419 MEXICO: FILL FINISH MANUFACTURING MARKET, BY PRODUCT, 2023-2030 (USD MILLION)

- TABLE 420 MEXICO: FILL FINISH MANUFACTURING MARKET FOR CONSUMABLES, BY TYPE, 2023-2030 (USD MILLION)

- TABLE 421 MEXICO: FILL FINISH MANUFACTURING MARKET FOR PRE-FILLABLE SYRINGES, BY COMPONENT, 2023-2030 (USD MILLION)

- TABLE 422 MEXICO: FILL FINISH MANUFACTURING MARKET FOR PREFILLED SYRINGES, BY MATERIAL, 2023-2030 (USD MILLION)

- TABLE 423 MEXICO: FILL FINISH MANUFACTURING MARKET FOR VIALS, BY MATERIAL, 2023-2030 (USD MILLION)

- TABLE 424 MEXICO: FILL FINISH MANUFACTURING MARKET FOR VIAL STOPPERS, BY TYPE, 2023-2030 (USD MILLION)

- TABLE 425 MEXICO: FILL FINISH MANUFACTURING MARKET FOR INSTRUMENTS, BY SYSTEM TYPE, 2023-2030 (USD MILLION)

- TABLE 426 MEXICO: FILL FINISH MANUFACTURING MARKET FOR INSTRUMENTS, BY MACHINE TYPE, 2023-2030 (USD MILLION)

- TABLE 427 MEXICO: FILL FINISH MANUFACTURING MARKET, BY END USER, 2023-2030 (USD MILLION)

- TABLE 428 REST OF LATIN AMERICA: FILL FINISH MANUFACTURING MARKET, BY PRODUCT, 2023-2030 (USD MILLION)

- TABLE 429 REST OF LATIN AMERICA: FILL FINISH MANUFACTURING MARKET FOR CONSUMABLES, BY TYPE, 2023-2030 (USD MILLION)

- TABLE 430 REST OF LATIN AMERICA: FILL FINISH MANUFACTURING MARKET FOR PRE-FILLABLE SYRINGES, BY COMPONENT, 2023-2030 (USD MILLION)

- TABLE 431 REST OF LATIN AMERICA: FILL FINISH MANUFACTURING MARKET FOR PREFILLED SYRINGES, BY MATERIAL, 2023-2030 (USD MILLION)

- TABLE 432 REST OF LATIN AMERICA: FILL FINISH MANUFACTURING MARKET FOR VIALS, BY MATERIAL, 2023-2030 (USD MILLION)

- TABLE 433 REST OF LATIN AMERICA: FILL FINISH MANUFACTURING MARKET FOR INSTRUMENTS, BY SYSTEM TYPE, 2023-2030 (USD MILLION)

- TABLE 434 REST OF LATIN AMERICA: FILL FINISH MANUFACTURING MARKET FOR INSTRUMENTS, BY MACHINE TYPE, 2023-2030 (USD MILLION)

- TABLE 435 REST OF LATIN AMERICA: FILL FINISH MANUFACTURING MARKET, BY END USER, 2023-2030 (USD MILLION)

- TABLE 436 MIDDLE EAST: KEY MACRO INDICATORS

- TABLE 437 MIDDLE EAST: FILL FINISH MANUFACTURING MARKET, BY COUNTRY, 2023-2030 (USD MILLION)

- TABLE 438 MIDDLE EAST: FILL FINISH MANUFACTURING MARKET, BY PRODUCT, 2023-2030 (USD MILLION)

- TABLE 439 MIDDLE EAST: FILL FINISH MANUFACTURING MARKET FOR CONSUMABLES, BY TYPE, 2023-2030 (USD MILLION)

- TABLE 440 MIDDLE EAST: FILL FINISH MANUFACTURING MARKET FOR PRE-FILLABLE SYRINGES, BY COMPONENT, 2023-2030 (USD MILLION)

- TABLE 441 MIDDLE EAST: FILL FINISH MANUFACTURING MARKET FOR PREFILLED SYRINGES, BY MATERIAL, 2023-2030 (USD MILLION)

- TABLE 442 MIDDLE EAST: FILL FINISH MANUFACTURING MARKET FOR VIALS, BY MATERIAL, 2023-2030 (USD MILLION)

- TABLE 443 MIDDLE EAST: FILL FINISH MANUFACTURING MARKET FOR VIALS, BY FORMAT, 2023-2030 (USD MILLION

- TABLE 444 MIDDLE EAST: FILL FINISH MANUFACTURING MARKET FOR VIAL STOPPERS, BY TYPE, 2023-2030 (USD MILLION)

- TABLE 445 MIDDLE EAST: FILL FINISH MANUFACTURING MARKET FOR INSTRUMENTS, BY SYSTEM TYPE, 2023-2030 (USD MILLION)

- TABLE 446 MIDDLE EAST: FILL FINISH MANUFACTURING MARKET FOR INSTRUMENTS BY MACHINE TYPE, 2023-2030 (USD MILLION)

- TABLE 447 MIDDLE EAST: FILL FINISH MANUFACTURING MARKET, BY END USER, 2023-2030 (USD MILLION)

- TABLE 448 GCC: FILL FINISH MANUFACTURING MARKET, BY COUNTRY, 2023-2030 (USD MILLION)