PUBLISHER: MarketsandMarkets | PRODUCT CODE: 1936065

PUBLISHER: MarketsandMarkets | PRODUCT CODE: 1936065

Ammonium Metatungstate Market by Raw Material, Form, Grade, Application, End-use Industry, and Region - Global Forecast to 2030

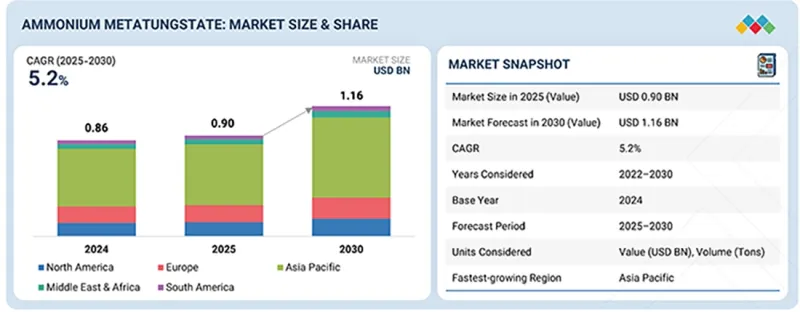

The ammonium metatungstate market is projected to grow from USD 0.90 billion in 2025 to USD 1.16 billion by 2030, at a CAGR of 5.2% during the forecast period.

| Scope of the Report | |

|---|---|

| Years Considered for the Study | 2022-2030 |

| Base Year | 2024 |

| Forecast Period | 2025-2030 |

| Units Considered | Value (USD Million), Volume (Tons) |

| Segments | Raw Material, Form, Grade, Application, End-use Industry, and Region |

| Regions covered | Europe, North America, Asia Pacific, the Middle East & Africa, and South America |

The reagent grade of ammonium metatungstate (AMT) is expected to be the second-fastest-growing grade in terms of value during the forecast period, driven by its expanding use in research, analytical applications, and high-precision industrial processes. Reagent-grade AMT offers superior purity and chemical consistency, making it suitable for laboratory-scale synthesis, catalyst development, and advanced material research where contamination control is critical. Its demand is rising, particularly in academic and industrial R&D sectors, as well as in niche applications such as electronics and specialty catalysts, where reproducibility and performance reliability are essential. Although high-purity or electronic-grade AMT dominates in certain high-tech segments, reagent-grade material continues to gain traction due to its balanced cost, availability, and quality specifications, positioning it as a key intermediate choice between technical and ultra-high-purity grades in the evolving AMT market landscape.

''In terms of value, catalyst is expected to be the fastest-growing in the overall AMT market during the forecast period.''

This growth is supported by the accelerating global transition toward cleaner fuels and energy-efficient chemical processes. AMT serves as a critical precursor for manufacturing tungsten-based catalysts used in hydroprocessing, oxidative coupling, and selective catalytic reduction (SCR) systems. Its unique combination of acidity, oxidation potential, and thermal stability enhances catalytic performance, making it highly effective in refining, petrochemical, and environmental applications. Beyond traditional hydrocracking and desulfurization uses, the material is increasingly being explored for green chemistry innovations such as biomass conversion, CO2 utilization, and ammonia decomposition for hydrogen production. These emerging sustainable technologies are creating new, high-value demand streams for AMT-derived catalysts. Additionally, as refineries and chemical plants modernize to meet stricter emission norms and process efficiency goals, the shift toward tungsten-based catalyst systems is expected to further accelerate the growth of this application segment.

.

"During the forecast period, the chemical end-use industry is projected to register the fastest growth during the forecast period."

Driven by the rising adoption of tungsten-based intermediates in advanced chemical synthesis and catalytic processes. AMT is increasingly being used as a key ingredient in the manufacture of high-performance catalysts, specialty tungsten compounds, and functional oxides that serve as building blocks for a variety of downstream products. The shift toward cleaner and more energy-efficient chemical production is further stimulating demand, as AMT enables high activity and selectivity in catalytic reactions, reducing waste and improving process economics. Additionally, growth in fine and specialty chemical manufacturing, including advanced coatings, polymer modifiers, and environmental catalysts, is creating new opportunities for AMT utilization. Many chemical producers are also investing in closed-loop tungsten recovery systems, using AMT as a recyclable and environmentally compatible intermediate, aligning with sustainability and circular economy trends. This combination of performance, versatility, and environmental compliance positions the chemical industry as a key growth driver for the global AMT market.

"The AMT market in Europe is projected to register the second-largest market share during the forecast period."

This growth is supported by the region's strong industrial base, advanced technological capabilities, and growing emphasis on sustainable manufacturing. The region hosts several leading tungsten chemical producers and refiners, particularly in Germany, Austria, and the UK, which have well-established infrastructure for high-purity tungsten processing. Europe's mature petrochemical, automotive, and aerospace industries are key consumers of AMT-based catalysts and materials, driven by strict environmental and performance standards. The ongoing transition toward low-emission fuels and the adoption of circular economy models are encouraging refiners and chemical manufacturers to integrate AMT in catalyst systems and tungsten recovery loops. Additionally, robust R&D initiatives, supported by the European Green Deal and investments in clean energy technologies, are fostering innovation in tungsten-based catalysts and electronic materials. This combination of regulatory push, technological advancement, and industrial maturity positions Europe as a strategically important and stable market, maintaining its status as the second-largest regional hub in the global AMT landscape.

This study has been validated through primary interviews with industry experts globally. These primary sources have been divided into the following three categories:

- By Company Type: Tier 1 - 60%, Tier 2 - 20%, and Tier 3 - 20%

- By Designation: C Level - 33%, Director Level - 33%, and Managers - 34%

- By Region: North America - 20%, Europe - 25%, Asia Pacific - 25%, Middle East & Africa - 15%, and South America - 15%

The report provides a comprehensive analysis of company profiles:

Prominent companies in this market include H.C. Starck Tungsten GmbH (Germany), Global Tungsten & Powders (US), Masan High-Tech Materials Corporation (Vietnam), Ganzhou Grand Sea Tungsten Co., Ltd. (China), Ereztech LLC (US), Ganzhou CF Tungsten Co., Ltd (China), United Wolfram (India), ATT Advanced Elemental Materials Co., Ltd. (US), Noah Chemicals (US), and North Metal & Chemical Co. (US).

Research Coverage

This research report categorizes the AMT market by raw material (virgin ore route, secondary/recycled route), form (powder, aqueous solution, crystalline), grade (standard grade, high-purity grade, reagent grade), application (catalysts, pigments, metal finishing, x-ray shielding, analytical chemistry, glass & ceramic production, other applications), end-use industry (chemical, electronics, medical, aerospace & defense, metallurgy, other end-use industries), and region (North America, Europe, Asia Pacific, Middle East & Africa, and South America). The scope of the report includes detailed information about the major factors influencing the growth of the AMT market, such as drivers, restraints, challenges, and opportunities. A thorough examination of the key industry players has been conducted in order to provide insights into their business overview, solutions, and services, key strategies, contracts, partnerships, and agreements. Product launches, mergers and acquisitions, and recent developments in the AMT market are all covered. This report includes a competitive analysis of upcoming startups in the AMT market ecosystem.

Reasons to buy this report:

The report will help the market leaders/new entrants in this market with information on the closest approximations of the revenue numbers for the overall AMT market and the subsegments. This report will help stakeholders understand the competitive landscape and gain more insights to position their businesses better and plan suitable go-to-market strategies. The report also helps stakeholders understand the pulse of the market and provides them with information on key market drivers, restraints, challenges, and opportunities.

The report provides insights on the following pointers:

- Analysis of key drivers (regulatory compliance in end-use industries, technological advancement, and performance superiority), restraints (volatility in raw material prices and technical complexity in downstream applications), opportunities (high growth technology sector and circular economy and recycling), and challenges (supply chain vulnerabilities)

- Product Development/Innovation: Detailed insights on upcoming technologies, research & development activities, and service launches in the AMT market.

- Market Development: Comprehensive information about lucrative markets - the report analyses the AMT market across varied regions.

- Market Diversification: Exhaustive information about services, untapped geographies, recent developments, and investments in the AMT market

- Competitive Assessment: In-depth assessment of market shares, growth strategies, and service offerings of leading players like H.C. Starck Tungsten GmbH (Germany), Global Tungsten & Powders (US), Masan High-Tech Materials Corporation (Vietnam), Ganzhou Grand Sea Tungsten Co., Ltd. (China), Ereztech LLC (US), Ganzhou CF Tungsten Co., Ltd. (China), United Wolfram (India), ATT Advanced Elemental Materials Co., Ltd. (US), Noah Chemicals (US), and North Metal & Chemical Co. (US).

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 STUDY OBJECTIVES

- 1.2 MARKET DEFINITION

- 1.3 STUDY SCOPE

- 1.3.1 AMMONIUM METATUNGSTATE MARKET SEGMENTATION AND REGIONAL SCOPE

- 1.3.2 INCLUSIONS AND EXCLUSIONS

- 1.3.3 YEARS CONSIDERED

- 1.4 CURRENCY CONSIDERED

- 1.5 UNITS CONSIDERED

- 1.6 STAKEHOLDERS

2 RESEARCH METHODOLOGY

- 2.1 RESEARCH DATA

- 2.1.1 SECONDARY DATA

- 2.1.1.1 List of key secondary sources

- 2.1.1.2 Key data from secondary sources

- 2.1.2 PRIMARY DATA

- 2.1.2.1 Key data from primary sources

- 2.1.2.2 List of primary interview participants-demand and supply side

- 2.1.2.3 Key industry insights

- 2.1.2.4 Breakdown of interviews with experts

- 2.1.1 SECONDARY DATA

- 2.2 MARKET SIZE ESTIMATION

- 2.2.1 BOTTOM-UP APPROACH

- 2.2.2 TOP-DOWN APPROACH

- 2.3 FORECAST NUMBER CALCULATION

- 2.4 DATA TRIANGULATION

- 2.5 FACTOR ANALYSIS

- 2.6 ASSUMPTIONS

- 2.7 LIMITATIONS & RISKS

3 EXECUTIVE SUMMARY

4 PREMIUM INSIGHTS

- 4.1 OPPORTUNITIES FOR PLAYERS IN AMMONIUM METATUNGSTATE MARKET

- 4.2 AMMONIUM METATUNGSTATE MARKET, BY RAW MATERIAL

- 4.3 AMMONIUM METATUNGSTATE MARKET, BY FORM

- 4.4 AMMONIUM METATUNGSTATE MARKET, BY GRADE

- 4.5 AMMONIUM METATUNGSTATE MARKET, BY APPLICATION

- 4.6 AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY

- 4.7 AMMONIUM METATUNGSTATE MARKET, BY KEY COUNTRY

5 MARKET OVERVIEW

- 5.1 INTRODUCTION

- 5.2 MARKET DYNAMICS

- 5.2.1 DRIVERS

- 5.2.1.1 Regulatory compliance in end-use industries

- 5.2.1.2 Technological advancement and performance superiority

- 5.2.2 RESTRAINTS

- 5.2.2.1 Volatility in raw material prices

- 5.2.2.2 Technical complexity in downstream applications

- 5.2.3 OPPORTUNITIES

- 5.2.3.1 High-growth technology sectors

- 5.2.3.2 Circular economy and recycling

- 5.2.4 CHALLENGES

- 5.2.4.1 Supply chain vulnerabilities

- 5.2.4.2 High barriers to new production

- 5.2.1 DRIVERS

- 5.3 PORTER'S FIVE FORCES ANALYSIS

- 5.3.1 BARGAINING POWER OF SUPPLIERS

- 5.3.2 BARGAINING POWER OF BUYERS

- 5.3.3 THREAT OF NEW ENTRANTS

- 5.3.4 THREAT OF SUBSTITUTES

- 5.3.5 INTENSITY OF COMPETITIVE RIVALRY

- 5.4 MACROECONOMIC INDICATORS

- 5.4.1 GLOBAL GDP TRENDS

- 5.5 VALUE CHAIN ANALYSIS

- 5.5.1 RAW MATERIAL SUPPLIERS

- 5.5.2 MANUFACTURERS

- 5.5.3 DISTRIBUTORS

- 5.5.4 DOWNSTREAM (PRODUCT MANUFACTURING)

- 5.5.5 END USERS

- 5.6 ECOSYSTEM ANALYSIS

- 5.7 TECHNOLOGY ANALYSIS

- 5.7.1 KEY TECHNOLOGIES

- 5.7.1.1 Next-generation battery anodes

- 5.7.1.2 Biomedical and environmental applications

- 5.7.1.3 Green hydrogen and carbon utilization

- 5.7.2 ADJACENT TECHNOLOGIES

- 5.7.2.1 Innovations in tungsten precursor synthesis and recycling

- 5.7.2.2 Advanced catalyst manufacturing and design

- 5.7.3 COMPLEMENTARY TECHNOLOGIES

- 5.7.3.1 Miniaturization in electronics

- 5.7.3.2 Advanced medical imaging

- 5.7.1 KEY TECHNOLOGIES

- 5.8 TRENDS/DISRUPTIONS IMPACTING CUSTOMER BUSINESS

- 5.9 TRADE ANALYSIS

- 5.9.1 EXPORT SCENARIO

- 5.9.2 IMPORT SCENARIO

- 5.10 CASE STUDY ANALYSIS

- 5.10.1 SUSTAINABLE PRODUCTION OF AMMONIUM METATUNGSTATE VIA REVERSE OSMOSIS

- 5.10.2 AMMONIUM METATUNGSTATE IN REFORMING CATALYSTS FOR HYDROGEN PRODUCTION

- 5.10.3 AMT IN CATALYST PREPARATION FOR NOx SCR - RESEARCH APPLICATION

- 5.11 REGULATORY LANDSCAPE

- 5.11.1 REGULATIONS

- 5.11.1.1 Europe

- 5.11.1.2 Asia Pacific

- 5.11.1.3 North America

- 5.11.2 REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- 5.11.1 REGULATIONS

- 5.12 KEY STAKEHOLDERS & BUYING CRITERIA

- 5.12.1 KEY STAKEHOLDERS IN BUYING PROCESS

- 5.12.2 BUYING CRITERIA

- 5.13 KEY CONFERENCES AND EVENTS, 2025-2026

- 5.14 PRICING ANALYSIS

- 5.14.1 AVERAGE SELLING PRICE TREND, BY REGION

- 5.14.2 AVERAGE SELLING PRICE TREND, BY APPLICATION

- 5.15 INVESTMENT AND FUNDING SCENARIO

- 5.16 PATENT ANALYSIS

- 5.16.1 APPROACH

- 5.16.2 DOCUMENT TYPES

- 5.16.3 PUBLICATION TRENDS, 2014-2024

- 5.16.4 INSIGHTS

- 5.16.5 LEGAL STATUS OF PATENTS

- 5.16.6 JURISDICTION ANALYSIS FROM 2014 TO 2024

- 5.16.7 TOP COMPANIES/APPLICANTS

- 5.16.8 TOP 10 PATENT OWNERS (US), 2014-2024

- 5.17 IMPACT OF 2025 US TARIFF ON AMMONIUM METATUNGSTATE MARKET

- 5.17.1 INTRODUCTION

- 5.17.2 KEY TARIFF RATES

- 5.17.3 PRICE IMPACT ANALYSIS

- 5.17.4 IMPACT ON KEY COUNTRIES/REGIONS

- 5.17.4.1 North America

- 5.17.4.2 Europe

- 5.17.4.3 Asia Pacific

- 5.17.5 IMPACT ON END-USE INDUSTRIES

6 AMMONIUM METATUNGSTATE MARKET, BY TYPE

- 6.1 INTRODUCTION

- 6.2 PURITY 99%

- 6.2.1 INDUSTRIAL-GRADE AMT FOR CATALYSTS AND TUNGSTEN POWDERS

- 6.3 PURITY 98%

- 6.3.1 AMT FOR CONVENTIONAL INDUSTRIAL APPLICATIONS

- 6.4 OTHERS

7 AMMONIUM METATUNGSTATE MARKET, BY RAW MATERIAL

- 7.1 INTRODUCTION

- 7.2 VIRGIN ORE ROUTE (WO3 FROM PRIMARY ORES)

- 7.2.1 INDUSTRIAL-GRADE AMT DERIVED FROM PRIMARY TUNGSTEN ORES

- 7.3 SECONDARY/RECYCLED ROUTE

- 7.3.1 AMT PRODUCTION VIA TUNGSTEN SCRAP AND CARBIDE RECYCLING

8 AMMONIUM METATUNGSTATE MARKET, BY FORM

- 8.1 INTRODUCTION

- 8.2 POWDER

- 8.2.1 AMT POWDERS TO DRIVE EFFICIENCY IN TUNGSTEN PROCESSING

- 8.3 AQUEOUS SOLUTION

- 8.3.1 AQUEOUS SOLUTIONS TO DRIVE GROWTH IN CATALYST INDUSTRY

- 8.4 CRYSTALLINE

- 8.4.1 HIGH-PURITY CRYSTALLINE AMT WIDELY USED IN ADVANCED TUNGSTEN APPLICATIONS

9 AMMONIUM METATUNGSTATE MARKET, BY GRADE

- 9.1 INTRODUCTION

- 9.2 STANDARD GRADE

- 9.2.1 COST-OPTIMIZED SOLUTION FOR BULK MANUFACTURING

- 9.3 HIGH PURITY GRADE

- 9.3.1 ENABLING ADVANCED APPLICATIONS IN ELECTRONICS AND CATALYSIS

- 9.4 REAGENT GRADE

- 9.4.1 SIGNIFICANCE OF REAGENT GRADE AMT IN EARLY-STAGE MATERIAL DEVELOPMENT

10 AMMONIUM METATUNGSTATE MARKET, BY APPLICATION

- 10.1 INTRODUCTION

- 10.2 CATALYST

- 10.2.1 IMPORTANCE IN PETROCHEMICAL AND ENVIRONMENTAL SECTORS

- 10.3 PIGMENTS

- 10.3.1 SUPERIOR COLOR RETENTION UNDER EXTREME CONDITIONS

- 10.4 METAL FINISHING

- 10.4.1 PROCESS-OPTIMIZED AMT FOR INDUSTRIAL APPLICATIONS

- 10.5 X-RAY SHIELDING

- 10.5.1 GROWING DEMAND FOR RADIATION PROTECTION IN HEALTHCARE FACILITIES

- 10.6 ANALYTICAL CHEMISTRY

- 10.6.1 ENABLES SENSITIVE DETECTION OF TRACE METALS AND ANIONS

- 10.7 GLASS & CERAMIC PRODUCTION

- 10.7.1 IMPROVES THERMAL STABILITY AND HEAT RESISTANCE IN GLASS AND CERAMICS

- 10.8 OTHER APPLICATIONS

11 AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY

- 11.1 INTRODUCTION

- 11.2 CHEMICAL & PETROCHEMICAL

- 11.2.1 DEMAND FOR CLEANER FUELS TO DRIVE MARKET

- 11.3 ELECTRONICS

- 11.3.1 HIGH-PURITY AMMONIUM METATUNGSTATE ESSENTIAL FOR ELECTRONICS INDUSTRY

- 11.4 MEDICAL

- 11.4.1 REGULATORY PRESSURE ON LEAD SHIELDING TO PROVIDE OPPORTUNITY FOR AMMONIUM METATUNGSTATE

- 11.5 AEROSPACE & DEFENSE

- 11.5.1 DEMAND FOR AMMONIUM METATUNGSTATE OF HIGH SPECIALIZATION AND QUALITY TO DRIVE MARKET

- 11.6 METALLURGY

- 11.6.1 WIDELY USED FOR MAKING SUBSTRATE FOR SEMICONDUCTOR DEVICES

- 11.7 OTHER END-USE INDUSTRIES

12 AMMONIUM METATUNGSTATE MARKET, BY REGION

- 12.1 INTRODUCTION

- 12.2 NORTH AMERICA

- 12.2.1 US

- 12.2.1.1 Government support to semiconductor fabrication industry to drive demand

- 12.2.2 CANADA

- 12.2.2.1 Oil sands processing and chemical exports are strong drivers for use of ammonium metatungstate

- 12.2.3 MEXICO

- 12.2.3.1 Country's transition to trade hub to drive market

- 12.2.1 US

- 12.3 ASIA PACIFIC

- 12.3.1 CHINA

- 12.3.1.1 Largest market for ammonium metatungstate

- 12.3.2 INDIA

- 12.3.2.1 Growing semiconductor industry through government initiative to drive market

- 12.3.3 JAPAN

- 12.3.3.1 Initiatives to restabilize semiconductor industry to drive demand for high-quality ammonium metatungstate

- 12.3.4 SOUTH KOREA

- 12.3.4.1 Expansion of electronics industry to directly drive ammonium metatungstate demand

- 12.3.5 REST OF ASIA PACIFIC

- 12.3.1 CHINA

- 12.4 EUROPE

- 12.4.1 GERMANY

- 12.4.1.1 Growth of chemical industry to drive market

- 12.4.2 FRANCE

- 12.4.2.1 High quality ammonium metatungstate to drive market

- 12.4.3 UK

- 12.4.3.1 Reliance on local sourcing for growing electronics industry to drive market

- 12.4.4 ITALY

- 12.4.4.1 Coatings for high purity materials to drive demand for ammonium metatungstate

- 12.4.5 SPAIN

- 12.4.5.1 Growing electronic base to support market

- 12.4.6 REST OF EUROPE

- 12.4.1 GERMANY

- 12.5 MIDDLE EAST & AFRICA

- 12.5.1 GCC COUNTRIES

- 12.5.1.1 Saudi Arabia

- 12.5.1.1.1 Vision 2030 to play major role in driving market

- 12.5.1.2 UAE

- 12.5.1.2.1 Government's initiative to diversify economy to drive market

- 12.5.1.3 Rest of GCC

- 12.5.1.1 Saudi Arabia

- 12.5.2 SOUTH AFRICA

- 12.5.2.1 Ammonium metatungstate demand is directly linked with growing chemical industry

- 12.5.3 REST OF MIDDLE EAST & AFRICA

- 12.5.1 GCC COUNTRIES

- 12.6 SOUTH AMERICA

- 12.6.1 BRAZIL

- 12.6.1.1 Government initiatives to drive market

- 12.6.2 ARGENTINA

- 12.6.2.1 Focus on chemical sector to drive market

- 12.6.3 REST OF SOUTH AMERICA

- 12.6.1 BRAZIL

13 COMPETITIVE LANDSCAPE

- 13.1 OVERVIEW

- 13.2 KEY PLAYER STRATEGIES/RIGHT TO WIN, 2021-2025

- 13.3 REVENUE ANALYSIS

- 13.4 MARKET SHARE ANALYSIS

- 13.4.1 GANZHOU GRAND SEA TUNGSTEN CO., LTD.

- 13.4.2 XIAMEN TUNGSTEN CO., LTD.

- 13.4.3 H.C. STARCK TUNGSTEN GMBH

- 13.4.4 GLOBAL TUNGSTEN & POWDERS

- 13.4.5 GANZHOU CF TUNGSTEN CO., LTD

- 13.5 COMPANY VALUATION AND FINANCIAL METRICS

- 13.6 PRODUCT COMPARISON ANALYSIS

- 13.7 COMPANY EVALUATION MATRIX: KEY PLAYERS, 2024

- 13.7.1 STARS

- 13.7.2 EMERGING LEADERS

- 13.7.3 PERVASIVE PLAYERS

- 13.7.4 PARTICIPANTS

- 13.7.5 COMPANY FOOTPRINT: KEY PLAYERS, 2024

- 13.7.5.1 Company footprint

- 13.7.5.2 Region footprint

- 13.7.5.3 Type footprint

- 13.7.5.4 Raw material footprint

- 13.7.5.5 Form footprint

- 13.7.5.6 Grade footprint

- 13.7.5.7 Application footprint

- 13.7.5.8 End-use industry footprint

- 13.8 COMPANY EVALUATION MATRIX: STARTUPS/SMES, 2024

- 13.8.1 PROGRESSIVE COMPANIES

- 13.8.2 RESPONSIVE COMPANIES

- 13.8.3 DYNAMIC COMPANIES

- 13.8.4 STARTING BLOCKS

- 13.8.5 COMPETITIVE BENCHMARKING: KEY STARTUPS/SMES, 2024

- 13.8.5.1 Detailed list of key startups/SMEs

- 13.8.5.2 Competitive benchmarking of key startups/SMEs

- 13.9 COMPETITIVE SCENARIO

- 13.9.1 DEALS

14 COMPANY PROFILES

- 14.1 KEY PLAYERS

- 14.1.1 GANZHOU GRAND SEA TUNGSTEN CO., LTD.

- 14.1.1.1 Business overview

- 14.1.1.2 Products/Solutions/Services offered

- 14.1.1.3 MnM view

- 14.1.2 XIAMEN TUNGSTEN CO., LTD.

- 14.1.2.1 Business overview

- 14.1.2.2 Products/Solutions/Services offered

- 14.1.2.3 MnM view

- 14.1.3 H.C. STARCK TUNGSTEN GMBH

- 14.1.3.1 Business overview

- 14.1.3.2 Products/Solutions/Services offered

- 14.1.3.3 Recent developments

- 14.1.3.3.1 Deals

- 14.1.3.4 MnM view

- 14.1.3.4.1 Key strengths

- 14.1.3.4.2 Strategic choices

- 14.1.3.4.3 Weaknesses and competitive threats

- 14.1.4 GLOBAL TUNGSTEN & POWDERS

- 14.1.4.1 Business overview

- 14.1.4.2 Products/Solutions/Services offered

- 14.1.4.3 Recent developments

- 14.1.4.3.1 Deals

- 14.1.4.4 MnM view

- 14.1.4.4.1 Key strengths

- 14.1.4.4.2 Strategic choices

- 14.1.4.4.3 Weaknesses and competitive threats

- 14.1.5 GANZHOU CF TUNGSTEN CO., LTD

- 14.1.5.1 Business overview

- 14.1.5.2 Products/Solutions/Services offered

- 14.1.5.3 MnM view

- 14.1.6 MASAN HIGH-TECH MATERIALS CORPORATION

- 14.1.6.1 Business overview

- 14.1.6.2 Products/Solutions/Services offered

- 14.1.6.3 MnM view

- 14.1.7 EREZTECH LLC

- 14.1.7.1 Business overview

- 14.1.7.2 Products/Solutions/Services offered

- 14.1.7.3 MnM view

- 14.1.8 UNITED WOLFRAM

- 14.1.8.1 Business overview

- 14.1.8.2 Products/Solutions/Services offered

- 14.1.8.3 MnM view

- 14.1.9 ATT ADVANCED ELEMENTAL MATERIALS CO., LTD.

- 14.1.9.1 Business overview

- 14.1.9.2 Products/Solutions/Services offered

- 14.1.9.3 MnM view

- 14.1.10 NOAH CHEMICALS

- 14.1.10.1 Business overview

- 14.1.10.2 Products/Solutions/Services offered

- 14.1.10.3 MnM view

- 14.1.11 NORTH METAL & CHEMICAL CO.

- 14.1.11.1 Business overview

- 14.1.11.2 Products/Solutions/Services offered

- 14.1.11.3 MnM view

- 14.1.1 GANZHOU GRAND SEA TUNGSTEN CO., LTD.

- 14.2 OTHER KEY PLAYERS

- 14.2.1 NINGBO INNO PHARMCHEM CO., LTD.

- 14.2.2 W&Q METAL PRODUCTS CO., LTD.

- 14.2.3 PROCHEM, INC.

- 14.2.4 NIPPON INORGANIC COLOUR & CHEMICAL CO., LTD.

- 14.2.5 SHANGHAI HUZHENG INDUSTRIAL CO., LTD.

- 14.2.6 ZHUZHOU CEMENTED CARBIDE GROUP CORP., LTD.

- 14.2.7 UNILONG INDUSTRY CO., LTD.

- 14.2.8 CAS CHEMICAL

- 14.2.9 MUBY CHEMICALS

- 14.2.10 MARUTI ENTERPRISE

15 APPENDIX

- 15.1 DISCUSSION GUIDE

- 15.2 KNOWLEDGESTORE: MARKETSANDMARKETS' SUBSCRIPTION PORTAL

- 15.3 CUSTOMIZATION OPTIONS

- 15.4 RELATED REPORTS

- 15.5 AUTHOR DETAILS

List of Tables

- TABLE 1 LIST OF KEY SECONDARY SOURCES

- TABLE 2 KEY REGULATIONS CREATING DEMAND FOR AMMONIUM METATUNGSTATE

- TABLE 3 AMMONIUM METATUNGSTATE MARKET: IMPACT OF PORTER'S FIVE FORCES

- TABLE 4 PROJECTED REAL GDP GROWTH (ANNUAL PERCENT CHANGE) OF KEY COUNTRIES, 2021-2030

- TABLE 5 ROLE OF COMPANIES IN ECOSYSTEM

- TABLE 6 EXPORT DATA HS CODE 284180-COMPLIANT PRODUCTS, BY COUNTRY (USD THOUSAND)

- TABLE 7 IMPORT DATA HS CODE 284180-COMPLIANT PRODUCTS, BY COUNTRY (USD THOUSAND)

- TABLE 8 AMMONIUM METATUNGSTATE MARKET: LIST OF REGULATORY BODIES, GOVERNMENT AGENCIES, AND OTHER ORGANIZATIONS

- TABLE 9 INFLUENCE OF STAKEHOLDERS ON BUYING PROCESS OF KEY END-USE INDUSTRIES (%)

- TABLE 10 BUYING CRITERIA FOR KEY END-USE INDUSTRIES

- TABLE 11 AMMONIUM METATUNGSTATE MARKET: KEY CONFERENCES AND EVENTS, 2025-2026

- TABLE 12 AVERAGE SELLING PRICE TREND OF AMMONIUM METATUNGSTATE, BY REGION, 2022-2030 (USD/KG)

- TABLE 13 AVERAGE SELLING PRICE TREND, BY APPLICATION, 2022-2030 (USD/KG)

- TABLE 14 TOTAL PATENT COUNT, 2014-2024

- TABLE 15 TOP 10 PATENT OWNERS, 2014-2014

- TABLE 16 US-ADJUSTED RECIPROCAL TARIFF RATES

- TABLE 17 AMMONIUM METATUNGSTATE MARKET, BY RAW MATERIAL, 2022-2024 (USD MILLION)

- TABLE 18 AMMONIUM METATUNGSTATE MARKET, BY RAW MATERIAL, 2025-2030 (USD MILLION)

- TABLE 19 AMMONIUM METATUNGSTATE MARKET, BY RAW MATERIAL, 2022-2024 (TON)

- TABLE 20 AMMONIUM METATUNGSTATE MARKET, BY RAW MATERIAL, 2025-2030 (TON)

- TABLE 21 AMMONIUM METATUNGSTATE MARKET, BY FORM, 2022-2024 (USD MILLION)

- TABLE 22 AMMONIUM METATUNGSTATE MARKET, BY FORM, 2025-2030 (USD MILLION)

- TABLE 23 AMMONIUM METATUNGSTATE MARKET, BY FORM, 2022-2024 (TON)

- TABLE 24 AMMONIUM METATUNGSTATE MARKET, BY FORM, 2025-2030 (TON)

- TABLE 25 AMMONIUM METATUNGSTATE MARKET, BY GRADE, 2022-2024 (USD MILLION)

- TABLE 26 AMMONIUM METATUNGSTATE MARKET, BY GRADE, 2025-2030 (USD MILLION)

- TABLE 27 AMMONIUM METATUNGSTATE MARKET, BY GRADE, 2022-2024 (TON)

- TABLE 28 AMMONIUM METATUNGSTATE MARKET, BY GRADE, 2025-2030 (TON)

- TABLE 29 AMMONIUM METATUNGSTATE MARKET, BY APPLICATION, 2022-2024 (USD MILLION)

- TABLE 30 AMMONIUM METATUNGSTATE MARKET, BY APPLICATION, 2025-2030 (USD MILLION)

- TABLE 31 AMMONIUM METATUNGSTATE MARKET, BY APPLICATION, 2022-2024 (TON)

- TABLE 32 AMMONIUM METATUNGSTATE MARKET, BY APPLICATION, 2025-2030 (TON)

- TABLE 33 AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 34 AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 35 AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2022-2024 (TON)

- TABLE 36 AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2025-2030 (TON)

- TABLE 37 AMMONIUM METATUNGSTATE MARKET, BY REGION, 2022-2024 (USD MILLION)

- TABLE 38 AMMONIUM METATUNGSTATE MARKET, BY REGION, 2025-2030 (USD MILLION)

- TABLE 39 AMMONIUM METATUNGSTATE MARKET, BY REGION, 2022-2024 (TON)

- TABLE 40 AMMONIUM METATUNGSTATE MARKET, BY REGION, 2025-2030 (TON)

- TABLE 41 NORTH AMERICA: AMMONIUM METATUNGSTATE MARKET, BY COUNTRY, 2022-2024 (USD MILLION)

- TABLE 42 NORTH AMERICA: AMMONIUM METATUNGSTATE MARKET, BY COUNTRY, 2025-2030 (USD MILLION)

- TABLE 43 NORTH AMERICA: AMMONIUM METATUNGSTATE MARKET, BY COUNTRY, 2022-2024 (TON)

- TABLE 44 NORTH AMERICA: AMMONIUM METATUNGSTATE MARKET, BY COUNTRY, 2025-2030 (TON)

- TABLE 45 NORTH AMERICA: AMMONIUM METATUNGSTATE MARKET, BY APPLICATION, 2022-2024 (USD MILLION)

- TABLE 46 NORTH AMERICA: AMMONIUM METATUNGSTATE MARKET, BY APPLICATION, 2025-2030 (USD MILLION)

- TABLE 47 NORTH AMERICA: AMMONIUM METATUNGSTATE MARKET, BY APPLICATION, 2022-2024 (TON)

- TABLE 48 NORTH AMERICA: AMMONIUM METATUNGSTATE MARKET, BY APPLICATION, 2025-2030 (TON)

- TABLE 49 NORTH AMERICA: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 50 NORTH AMERICA: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 51 NORTH AMERICA: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2022-2024 (TON)

- TABLE 52 NORTH AMERICA: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2025-2030 (TON)

- TABLE 53 US: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 54 US: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 55 US: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2022-2024 (TON)

- TABLE 56 US: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2025-2030 (TON)

- TABLE 57 CANADA: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 58 CANADA: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 59 CANADA: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2022-2024 (TON)

- TABLE 60 CANADA: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2025-2030 (TON)

- TABLE 61 MEXICO: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 62 MEXICO: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 63 MEXICO: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2022-2024 (TON)

- TABLE 64 MEXICO: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2025-2030 (TON)

- TABLE 65 ASIA PACIFIC: AMMONIUM METATUNGSTATE MARKET, BY COUNTRY, 2022-2024 (USD MILLION)

- TABLE 66 ASIA PACIFIC: AMMONIUM METATUNGSTATE MARKET, BY COUNTRY, 2025-2030 (USD MILLION)

- TABLE 67 ASIA PACIFIC: AMMONIUM METATUNGSTATE MARKET, BY COUNTRY, 2022-2024 (TON)

- TABLE 68 ASIA PACIFIC: AMMONIUM METATUNGSTATE MARKET, BY COUNTRY, 2025-2030 (TON)

- TABLE 69 ASIA PACIFIC: AMMONIUM METATUNGSTATE MARKET, BY APPLICATION, 2022-2024 (USD MILLION)

- TABLE 70 ASIA PACIFIC: AMMONIUM METATUNGSTATE MARKET, BY APPLICATION, 2025-2030 (USD MILLION)

- TABLE 71 ASIA PACIFIC: AMMONIUM METATUNGSTATE MARKET, BY APPLICATION, 2022-2024 (TON)

- TABLE 72 ASIA PACIFIC: AMMONIUM METATUNGSTATE MARKET, BY APPLICATION, 2025-2030 (TON)

- TABLE 73 ASIA PACIFIC: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 74 ASIA PACIFIC: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 75 ASIA PACIFIC: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2022-2024 (TON)

- TABLE 76 ASIA PACIFIC: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2025-2030 (TON)

- TABLE 77 CHINA: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 78 CHINA: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 79 CHINA: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2022-2024 (TON)

- TABLE 80 CHINA: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2025-2030 (TON)

- TABLE 81 INDIA: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 82 INDIA: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 83 INDIA: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2022-2024 (TON)

- TABLE 84 INDIA: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2025-2030 (TON)

- TABLE 85 JAPAN: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 86 JAPAN: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 87 JAPAN: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2022-2024 (TON)

- TABLE 88 JAPAN: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2025-2030 (TON)

- TABLE 89 SOUTH KOREA: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 90 SOUTH KOREA: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 91 SOUTH KOREA: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2022-2024 (TON)

- TABLE 92 SOUTH KOREA: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2025-2030 (TON)

- TABLE 93 REST OF ASIA PACIFIC: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 94 REST OF ASIA PACIFIC: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 95 REST OF ASIA PACIFIC: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2022-2024 (TON)

- TABLE 96 REST OF ASIA PACIFIC: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2025-2030 (TON)

- TABLE 97 EUROPE: AMMONIUM METATUNGSTATE MARKET, BY COUNTRY, 2022-2024 (USD MILLION)

- TABLE 98 EUROPE: AMMONIUM METATUNGSTATE MARKET, BY COUNTRY, 2025-2030 (USD MILLION)

- TABLE 99 EUROPE: AMMONIUM METATUNGSTATE MARKET, BY COUNTRY, 2022-2024 (TON)

- TABLE 100 EUROPE: AMMONIUM METATUNGSTATE MARKET, BY COUNTRY, 2025-2030 (TON)

- TABLE 101 EUROPE: AMMONIUM METATUNGSTATE MARKET, BY APPLICATION, 2022-2024 (USD MILLION)

- TABLE 102 EUROPE: AMMONIUM METATUNGSTATE MARKET, BY APPLICATION, 2025-2030 (USD MILLION)

- TABLE 103 EUROPE: AMMONIUM METATUNGSTATE MARKET, BY APPLICATION, 2022-2024 (TON)

- TABLE 104 EUROPE: AMMONIUM METATUNGSTATE MARKET, BY APPLICATION, 2025-2030 (TON)

- TABLE 105 EUROPE: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 106 EUROPE: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 107 EUROPE: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2022-2024 (TON)

- TABLE 108 EUROPE: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2025-2030 (TON)

- TABLE 109 GERMANY: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 110 GERMANY: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 111 GERMANY: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2022-2024 (TON)

- TABLE 112 GERMANY: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2025-2030 (TON)

- TABLE 113 FRANCE: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 114 FRANCE: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 115 FRANCE: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2022-2024 (TON)

- TABLE 116 FRANCE: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2025-2030 (TON)

- TABLE 117 UK: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 118 UK: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 119 UK: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2022-2024 (TON)

- TABLE 120 UK: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2025-2030 (TON)

- TABLE 121 ITALY: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 122 ITALY: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 123 ITALY: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2022-2024 (TON)

- TABLE 124 ITALY: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2025-2030 (TON)

- TABLE 125 SPAIN: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 126 SPAIN: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 127 SPAIN: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2022-2024 (TON)

- TABLE 128 SPAIN: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2025-2030 (TON)

- TABLE 129 REST OF EUROPE: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 130 REST OF EUROPE: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 131 REST OF EUROPE: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2022-2024 (TON)

- TABLE 132 REST OF EUROPE: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2025-2030 (TON)

- TABLE 133 MIDDLE EAST & AFRICA: AMMONIUM METATUNGSTATE MARKET, BY COUNTRY, 2022-2024 (USD MILLION)

- TABLE 134 MIDDLE EAST & AFRICA: AMMONIUM METATUNGSTATE MARKET, BY COUNTRY, 2025-2030 (USD MILLION)

- TABLE 135 MIDDLE EAST & AFRICA: AMMONIUM METATUNGSTATE MARKET, BY COUNTRY, 2022-2024 (TON)

- TABLE 136 MIDDLE EAST & AFRICA: AMMONIUM METATUNGSTATE MARKET, BY COUNTRY, 2025-2030 (TON)

- TABLE 137 MIDDLE EAST & AFRICA: AMMONIUM METATUNGSTATE MARKET, BY APPLICATION, 2022-2024 (USD MILLION)

- TABLE 138 MIDDLE EAST & AFRICA: AMMONIUM METATUNGSTATE MARKET, BY APPLICATION, 2025-2030 (USD MILLION)

- TABLE 139 MIDDLE EAST & AFRICA: AMMONIUM METATUNGSTATE MARKET, BY APPLICATION, 2022-2024 (TON)

- TABLE 140 MIDDLE EAST & AFRICA: AMMONIUM METATUNGSTATE MARKET, BY APPLICATION, 2025-2030 (TON)

- TABLE 141 MIDDLE EAST & AFRICA: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 142 MIDDLE EAST & AFRICA: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 143 MIDDLE EAST & AFRICA: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2022-2024 (TON)

- TABLE 144 MIDDLE EAST & AFRICA: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2025-2030 (TON)

- TABLE 145 SAUDI ARABIA: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 146 SAUDI ARABIA: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 147 SAUDI ARABIA: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2022-2024 (TON)

- TABLE 148 SAUDI ARABIA: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2025-2030 (TON)

- TABLE 149 UAE: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 150 UAE: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 151 UAE: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2022-2024 (TON)

- TABLE 152 UAE: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2025-2030 (TON)

- TABLE 153 REST OF GCC: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 154 REST OF GCC: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 155 REST OF GCC: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2022-2024 (TON)

- TABLE 156 REST OF GCC: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2025-2030 (TON)

- TABLE 157 SOUTH AFRICA: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 158 SOUTH AFRICA: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 159 SOUTH AFRICA: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2022-2024 (TON)

- TABLE 160 SOUTH AFRICA: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2025-2030 (TON)

- TABLE 161 REST OF MIDDLE EAST & AFRICA: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 162 REST OF MIDDLE EAST & AFRICA: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 163 REST OF MIDDLE EAST & AFRICA: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2022-2024 (TON)

- TABLE 164 REST OF MIDDLE EAST & AFRICA: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2025-2030 (TON)

- TABLE 165 SOUTH AMERICA: AMMONIUM METATUNGSTATE MARKET, BY COUNTRY, 2022-2024 (USD MILLION)

- TABLE 166 SOUTH AMERICA: AMMONIUM METATUNGSTATE MARKET, BY COUNTRY, 2025-2030 (USD MILLION)

- TABLE 167 SOUTH AMERICA: AMMONIUM METATUNGSTATE MARKET, BY COUNTRY, 2022-2024 (TON)

- TABLE 168 SOUTH AMERICA: AMMONIUM METATUNGSTATE MARKET, BY COUNTRY, 2025-2030 (TON)

- TABLE 169 SOUTH AMERICA: AMMONIUM METATUNGSTATE MARKET, BY APPLICATION, 2022-2024 (USD MILLION)

- TABLE 170 SOUTH AMERICA: AMMONIUM METATUNGSTATE MARKET, BY APPLICATION, 2025-2030 (USD MILLION)

- TABLE 171 SOUTH AMERICA: AMMONIUM METATUNGSTATE MARKET, BY APPLICATION, 2022-2024 (TON)

- TABLE 172 SOUTH AMERICA: AMMONIUM METATUNGSTATE MARKET, BY APPLICATION, 2025-2030 (TON)

- TABLE 173 SOUTH AMERICA: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 174 SOUTH AMERICA: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 175 SOUTH AMERICA: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2022-2024 (TON)

- TABLE 176 SOUTH AMERICA: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2025-2030 (TON)

- TABLE 177 BRAZIL: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 178 BRAZIL: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 179 BRAZIL: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2022-2024 (TON)

- TABLE 180 BRAZIL: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2025-2030 (TON)

- TABLE 181 ARGENTINA: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 182 ARGENTINA: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 183 ARGENTINA: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2022-2024 (TON)

- TABLE 184 ARGENTINA: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2025-2030 (TON)

- TABLE 185 REST OF SOUTH AMERICA: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2022-2024 (USD MILLION)

- TABLE 186 REST OF SOUTH AMERICA: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2025-2030 (USD MILLION)

- TABLE 187 REST OF SOUTH AMERICA: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2022-2024 (TON)

- TABLE 188 REST OF SOUTH AMERICA: AMMONIUM METATUNGSTATE MARKET, BY END-USE INDUSTRY, 2025-2030 (TON)

- TABLE 189 AMMONIUM METATUNGSTATE MARKET: OVERVIEW OF STRATEGIES ADOPTED BY KEY MANUFACTURERS, 2021-2025

- TABLE 190 AMMONIUM METATUNGSTATE MARKET: DEGREE OF COMPETITION, 2024

- TABLE 191 AMMONIUM METATUNGSTATE MARKET: REGION FOOTPRINT

- TABLE 192 AMMONIUM METATUNGSTATE MARKET: TYPE FOOTPRINT

- TABLE 193 AMMONIUM METATUNGSTATE MARKET: RAW MATERIAL FOOTPRINT

- TABLE 194 AMMONIUM METATUNGSTATE MARKET: FORM FOOTPRINT

- TABLE 195 AMMONIUM METATUNGSTATE MARKET: GRADE FOOTPRINT

- TABLE 196 AMMONIUM METATUNGSTATE MARKET: APPLICATION FOOTPRINT

- TABLE 197 AMMONIUM METATUNGSTATE MARKET: END-USE INDUSTRY FOOTPRINT

- TABLE 198 AMMONIUM METATUNGSTATE MARKET: DETAILED LIST OF KEY STARTUPS/SMES

- TABLE 199 AMMONIUM METATUNGSTATE MARKET: COMPETITIVE BENCHMARKING OF STARTUPS/SMES

- TABLE 200 AMMONIUM METATUNGSTATE MARKET: DEALS, JANUARY 2021-JUNE 2025

- TABLE 201 GANZHOU GRAND SEA TUNGSTEN CO., LTD.: COMPANY OVERVIEW

- TABLE 202 GANZHOU GRAND SEA TUNGSTEN CO., LTD.: PRODUCTS/SOLUTIONS/ SERVICES OFFERED

- TABLE 203 XIAMEN TUNGSTEN CO., LTD.: COMPANY OVERVIEW

- TABLE 204 XIAMEN TUNGSTEN CO., LTD: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 205 H.C. STARCK TUNGSTEN GMBH: COMPANY OVERVIEW

- TABLE 206 H.C. STARCK TUNGSTEN GMBH: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 207 H.C. STARCK TUNGSTEN GMBH: DEALS, JANUARY 2021-JUNE 2025

- TABLE 208 GLOBAL TUNGSTEN & POWDERS: COMPANY OVERVIEW

- TABLE 209 GLOBAL TUNGSTEN & POWDERS: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 210 GLOBAL TUNGSTEN & POWDERS: DEALS, JANUARY 2021-JUNE 2025

- TABLE 211 GANZHOU CF TUNGSTEN CO., LTD: COMPANY OVERVIEW

- TABLE 212 GANZHOU CF TUNGSTEN CO., LTD: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 213 MASAN HIGH-TECH MATERIALS CORPORATION: COMPANY OVERVIEW

- TABLE 214 MASAN HIGH-TECH MATERIALS CORPORATION: PRODUCTS/SOLUTIONS/ SERVICES OFFERED

- TABLE 215 EREZTECH LLC: COMPANY OVERVIEW

- TABLE 216 EREZTECH LLC: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 217 UNITED WOLFRAM: COMPANY OVERVIEW

- TABLE 218 UNITED WOLFRAM: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 219 ATT ADVANCED ELEMENTAL MATERIALS CO., LTD.: COMPANY OVERVIEW

- TABLE 220 ATT ADVANCED ELEMENTAL MATERIALS CO., LTD.: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 221 NOAH CHEMICALS: COMPANY OVERVIEW

- TABLE 222 NOAH CHEMICALS: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 223 NORTH METAL & CHEMICAL CO.: COMPANY OVERVIEW

- TABLE 224 NORTH METAL & CHEMICAL CO.: PRODUCTS/SOLUTIONS/SERVICES OFFERED

- TABLE 225 NINGBO INNO PHARMCHEM CO., LTD.: COMPANY OVERVIEW

- TABLE 226 W&Q METAL PRODUCTS CO., LTD.: COMPANY OVERVIEW

- TABLE 227 PROCHEM, INC.: COMPANY OVERVIEW

- TABLE 228 NIPPON INORGANIC COLOUR & CHEMICAL CO., LTD.: COMPANY OVERVIEW

- TABLE 229 SHANGHAI HUZHENG INDUSTRIAL CO., LTD.: COMPANY OVERVIEW

- TABLE 230 ZHUZHOU CEMENTED CARBIDE GROUP CORP., LTD.: COMPANY OVERVIEW

- TABLE 231 UNILONG INDUSTRY CO., LTD.: COMPANY OVERVIEW

- TABLE 232 CAS CHEMICAL: COMPANY OVERVIEW

- TABLE 233 MUBY CHEMICALS: COMPANY OVERVIEW

- TABLE 234 MARUTI ENTERPRISE: COMPANY OVERVIEW

List of Figures

- FIGURE 1 AMMONIUM METATUNGSTATE MARKET SEGMENTATION AND REGIONAL SCOPE

- FIGURE 2 AMMONIUM METATUNGSTATE MARKET: RESEARCH DESIGN

- FIGURE 3 AMMONIUM METATUNGSTATE MARKET: BOTTOM-UP APPROACH

- FIGURE 4 AMMONIUM METATUNGSTATE MARKET: TOP-DOWN APPROACH

- FIGURE 5 AMMONIUM METATUNGSTATE MARKET SIZE ESTIMATION: TOP-DOWN APPROACH

- FIGURE 6 DEMAND-SIDE FORECAST

- FIGURE 7 AMMONIUM METATUNGSTATE MARKET: DATA TRIANGULATION

- FIGURE 8 VIRGIN ORE ROUTE TO BE PREFERRED RAW MATERIAL SOURCE BETWEEN 2025 AND 2030

- FIGURE 9 AQUEOUS SOLUTION FORM TO LEAD AMMONIUM METATUNGSTATE MARKET, 2025-2030

- FIGURE 10 STANDARD GRADE AMMONIUM METATUNGSTATE TO BE LARGEST SEGMENT, 2025-2030

- FIGURE 11 CATALYSTS APPLICATION TO DOMINATE AMMONIUM METATUNGSTATE MARKET, 2025-2030.

- FIGURE 12 CHEMICALS TO CAPTURE LARGEST SHARE IN AMMONIUM METATUNGSTATE MARKET

- FIGURE 13 ASIA PACIFIC TO BE LARGEST AND FASTEST-GROWING REGION BETWEEN 2025 AND 2030

- FIGURE 14 EMERGING ECONOMIES TO OFFER ATTRACTIVE OPPORTUNITIES DURING FORECAST PERIOD

- FIGURE 15 VIRGIN ORE ROUTE TO CAPTURE LARGER MARKET SHARE BY 2030

- FIGURE 16 AQUEOUS SOLUTION FORM TO LEAD MARKET DURING FORECAST PERIOD

- FIGURE 17 STANDARD GRADE TO LEAD MARKET DURING FORECAST PERIOD

- FIGURE 18 CATALYSTS TO LEAD MARKET DURING FORECAST PERIOD

- FIGURE 19 CHEMICAL INDUSTRY TO LEAD MARKET DURING FORECAST PERIOD

- FIGURE 20 MARKET IN CHINA TO REGISTER HIGHEST CAGR FROM 2025 TO 2030

- FIGURE 21 DRIVERS, RESTRAINTS, OPPORTUNITIES, AND CHALLENGES IN AMMONIUM METATUNGSTATE MARKET

- FIGURE 22 AMMONIUM METATUNGSTATE MARKET: PORTER'S FIVE FORCES ANALYSIS

- FIGURE 23 OVERVIEW OF AMMONIUM METATUNGSTATE MARKET VALUE CHAIN

- FIGURE 24 AMMONIUM METATUNGSTATE MARKET: ECOSYSTEM

- FIGURE 25 AMMONIUM METATUNGSTATE MARKET: TRENDS/DISRUPTIONS IMPACTING CUSTOMER BUSINESS

- FIGURE 26 EXPORT DATA FOR TOP 10 COUNTRIES

- FIGURE 27 IMPORT DATA FOR TOP 10 COUNTRIES

- FIGURE 28 INFLUENCE OF STAKEHOLDERS ON BUYING PROCESS OF KEY END-USE INDUSTRIES

- FIGURE 29 BUYING CRITERIA FOR KEY END-USE INDUSTRIES

- FIGURE 30 AVERAGE SELLING PRICE TREND OF AMMONIUM METATUNGSTATE, BY REGION (USD/KG), 2022-2024

- FIGURE 31 AVERAGE SELLING PRICE TREND, BY APPLICATION, 2022-2024 (USD/KG)

- FIGURE 32 AMMONIUM METATUNGSTATE MARKET: INVESTMENT AND FUNDING SCENARIO

- FIGURE 33 TOTAL NUMBER OF PATENTS FOR 2014-2024

- FIGURE 34 NUMBER OF PATENTS YEAR-WISE FROM 2014 TO 2024

- FIGURE 35 PATENT ANALYSIS, BY LEGAL STATUS

- FIGURE 36 TOP JURISDICTION, BY DOCUMENT, 2014-2024

- FIGURE 37 TOP 10 COMPANIES/APPLICANTS WITH HIGHEST NUMBER OF PATENTS, 2014-2024

- FIGURE 38 VIRGIN ORE ROUTE TO BE LARGER RAW MATERIAL SEGMENT OF AMMONIUM METATUNGSTATE MARKET BY 2030

- FIGURE 39 AQUEOUS SOLUTION SEGMENT TO HOLD LARGEST SHARE OF AMMONIUM METATUNGSTATE MARKET IN 2030

- FIGURE 40 STANDARD GRADE TO HOLD LARGEST SHARE OF AMMONIUM METATUNGSTATE MARKET IN 2030

- FIGURE 41 CATALYSTS TO HOLD LARGEST SHARE OF AMMONIUM METATUNGSTATE MARKET IN 2030

- FIGURE 42 CHEMICAL INDUSTRY TO ACCOUNT FOR LARGEST MARKET SHARE DURING FORECAST PERIOD

- FIGURE 43 INDIA TO GROW AT HIGHEST CAGR DURING FORECAST PERIOD

- FIGURE 44 NORTH AMERICA: AMMONIUM METATUNGSTATE MARKET SNAPSHOT

- FIGURE 45 ASIA PACIFIC: AMMONIUM METATUNGSTATE MARKET SNAPSHOT

- FIGURE 46 AMMONIUM METATUNGSTATE MARKET: REVENUE ANALYSIS OF KEY PLAYERS, 2022-2024 (USD BILLION)

- FIGURE 47 AMMONIUM METATUNGSTATE MARKET SHARE ANALYSIS, 2024

- FIGURE 48 AMMONIUM METATUNGSTATE MARKET: COMPANY VALUATION OF KEY COMPANIES, 2024 (USD BILLION)

- FIGURE 49 AMMONIUM METATUNGSTATE MARKET: FINANCIAL METRICS OF KEY COMPANIES, 2024

- FIGURE 50 AMMONIUM METATUNGSTATE MARKET: PRODUCT COMPARISON

- FIGURE 51 AMMONIUM METATUNGSTATE MARKET: COMPANY EVALUATION MATRIX (KEY PLAYERS), 2024

- FIGURE 52 AMMONIUM METATUNGSTATE MARKET: COMPANY FOOTPRINT

- FIGURE 53 AMMONIUM METATUNGSTATE MARKET: COMPANY EVALUATION MATRIX (STARTUPS/SMES), 2024

- FIGURE 54 MASAN HIGH-TECH MATERIALS CORPORATION: COMPANY SNAPSHOT