PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1687982

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1687982

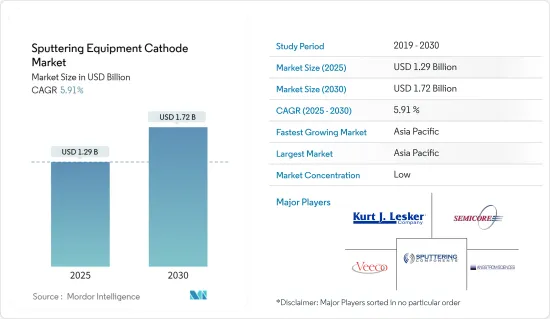

Sputtering Equipment Cathode - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030)

The Sputtering Equipment Cathode Market size is estimated at USD 1.29 billion in 2025, and is expected to reach USD 1.72 billion by 2030, at a CAGR of 5.91% during the forecast period (2025-2030).

The increasing applications of sputtering in the coating of components in the rapidly growing semiconductor industry is expected to be one of the primary factors that will drive the demand for these types of equipment over the forecast period.

Key Highlights

- The emergence of Artificial Intelligence across various end-user industries, such as aerospace and electronics, is expected to increase the demand for semiconductors, which will drive the market's growth. Moreover, the increasing use of semiconductors for implementing virtual reality in gaming is further expected to drive market growth.

- As companies move toward leveraging next-generation manufacturing methods, the processes such as magnetron sputtering technology are increasingly adopted by semiconductor manufacturing companies for enhanced efficiency and quality of semiconductors.

- Magnetron sputtering technology offers advantages such as high deposition rates, high purity films, extremely high adhesion of films, excellent coverage of steps and small features, ability to coat heat-sensitive substrates, ease of automation, high uniformity on large-area substrates, ease of sputtering any metal, alloy, or compound, and many more. These advantages lead to increased use of magnetron sputtering technology in the sputtering of semiconductors.

- The advancement in technology and increased investment in the research and development of new and alternate techniques in the manufacturing of semiconductors provide advantages such as enhanced performance, increased production rate, and many more, reducing the use of physical vapor deposition (PVD) methods. This impacts the market studied.

- The outbreak of the COVID-19 pandemic across the world significantly disrupted the supply chain and production of products in the market during the initial phase of 2020. Due to labor shortages, many of the package and testing plants in the various region reduced or even suspended operations. This also created a bottleneck for companies that depend on such back-end packages and testing capacity.

- Furthermore, the increased number of initiatives taken by major players, such as continuous investments in R&D to develop new manufacturing processes, is further expected to enhance the volume output of the process.

Sputtering Equipment Cathode Market Trends

Rise in the Application of Semiconductors is Expected to Drive the Market

- The demand for semiconductors is being driven by the increase in demand for consumer electronics, industrial tools & equipment, automotive products, networking, and communication products. And many more. These industries have been inspired by technology transitions such as wireless technologies (5G), Artificial intelligence, automation, etc.

- The trend of increasing numbers of Internet of Things (IoT) devices is expected to force the semiconductor industry to invest in this equipment for enhanced production capabilities.

- For instance, according to the recent forecasts of Semiconductor Equipment and Materials International (SEMI), silicon wafer shipments for semiconductor applications are expected to exceed 17,600 million square inches (MSI) by 2025 from 11,810 MSI in 2019.

- In the automotive industry increasing number of semiconductor products per vehicle and trends like autonomous and electric vehicles are increasing the demand for semiconductor manufacturing.

- The increase in applications of the Internet of Things is expected to boost the demand for semiconductors. Moreover, the wireless communications sector is expected to grow with the growth in 5G networks. Fifth-generation networks also indicate the likelihood of consumers upgrading their handsets/devices to drive applications of semiconductors globally.

- With the increasing production of semiconductors in various devices worldwide, the market will witness positive growth over the forecast period.

Asia-Pacific is Expected to Occupy Highest Market Share

- The Asia-Pacific region is expected to be the largest market for sputtering equipment, primarily owing to the increased semiconductor production in countries like China, South Korea, India, and Taiwan. Moreover, the increasing demand for PVD coatings from solar photovoltaic cells and the medical equipment industry is also expected to positively push the market growth during the forecast period.

- China, a global manufacturing hub, is expected to witness an increase in the production of various products such as electronics and automotive, among others, over the forecast period, which is expected to drive the market. Also, the automotive industry comprises various coated components using sputtering equipment. Also, the growth in the production of electric/hybrid vehicles is expected to impact the market.

- Japan holds a significant position in the semiconductor industry as it is home to some of the important IC chipset manufacturers and the electronics industry. According to WSTS, the semiconductor industry revenue in Japan for 2021 stood at USD 43.69 billion, and it is expected to reach USD 47.93 billion in 2022 and grow steadily in the future.

- Furthermore, technological innovations in the robotics industry in countries like China and Japan are projected to boost the demand for semiconductor coatings. The increasing demand for semiconductor chips is expected to be supported by the increased demand from the robotics industry.

- The Indian semiconductor ecosystem is robust, with most major global semiconductor players having their R&D centers in India. However, with supportive government policies, semiconductor manufacturing facilities are not significantly developed in the country. There are massive opportunities for the studied market.

- The India Electronics and Semiconductor Association stated that the semiconductor component market in the region is expected to be worth USD 32.35 billion by 2025 while witnessing a CAGR of 10.1% (2018 -2025). This indicates high potential activity in the country's electronics sector, leading to several opportunities for the market studied.

- In January 2021, the Ministry of Trade, Industry, and Energy announced that South Korea's ICT exports and imports increased by 3.8% and 3.9% to USD 183.6 billion and USD 112.6 billion, respectively, in 2020. The government also reported that in 2020, the country's semiconductor exports totaled USD 100.25 billion. The exports decreased by 1.5% in the first half of 2020; however, they increased by around 12.3% in the second half. Especially, system-on-chip exports increased by 17.8% to an all-time high of USD 30.3 billion. Memory chip exports increased by 1.5% to USD 63.9 billion.

Sputtering Equipment Cathode Industry Overview

The Sputtering Equipment Cathode Market is highly competitive owing to the presence of various large players supplying equipment in domestic and international markets. The market appears to be consolidated as few of the players currently dominate the market. Major players in the market are adopting strategies like product innovation and partnerships to expand their reach and stay ahead of the competition. Some of the major players in the market are Semicore Equipment, Inc., Sputtering Components, Inc., Angstrom Sciences Inc., and Veeco Instruments, Inc., among others.

- January 2022 - Kurt J. Lesker Company (KJLC) has announced that it has substantially acquired all of the KDF Electronics & Vacuum Services (KDF Technologies) assets through an asset purchase agreement. From the beginning of 2022, KDF Electronics & Vacuum Services will become known as KDF Technologies. KDF will continue to operate independently of KJLC while leveraging some shared services.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definitions

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Value Chain Analysis

- 4.3 Industry Attractiveness - Porter's Five Forces Analysis

- 4.3.1 Bargaining Power of Suppliers

- 4.3.2 Bargaining Power of Buyers

- 4.3.3 Threat of New Entrants

- 4.3.4 Threat of Substitutes

- 4.3.5 Intensity of Competitive Rivalry

- 4.4 Assesment of Impact of COVID-19 on the Market

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Rise in the Applications of Semiconductors

- 5.1.2 Advancement in Technology Such as Magnetron Sputtering Technology

- 5.2 Market Restraints

- 5.2.1 Rise of Alternative Technologies Such as Thermal Evaporation

6 MARKET SEGMENTATION

- 6.1 By Product

- 6.1.1 Linear

- 6.1.2 Circular

- 6.2 By Geography

- 6.2.1 North America

- 6.2.1.1 United States

- 6.2.1.2 Canada

- 6.2.2 Europe

- 6.2.2.1 Germany

- 6.2.2.2 United Kingdom

- 6.2.2.3 France

- 6.2.2.4 Rest of Europe

- 6.2.3 Asia-Pacific

- 6.2.3.1 China

- 6.2.3.2 Japan

- 6.2.3.3 India

- 6.2.3.4 Rest of Asia-Pacific

- 6.2.4 Rest of the World

- 6.2.4.1 Latin America

- 6.2.4.2 Middle-East and Africa

- 6.2.1 North America

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Kurt J. Lesker Company

- 7.1.2 Veeco Instruments, Inc.

- 7.1.3 Semicore Equipment Inc.

- 7.1.4 Impact Coatings AB

- 7.1.5 AJA International Inc.

- 7.1.6 Soleras Advanced Coatings

- 7.1.7 Sputtering Components, Inc.

- 7.1.8 KDF Technologies

- 7.1.9 Angstrom Sciences, Inc.

- 7.1.10 Angstrom Engineering Inc.

8 INVESTMENT ANALYSIS

9 MARKET OPPORTUNITIES AND FUTURE TRENDS