PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1842542

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1842542

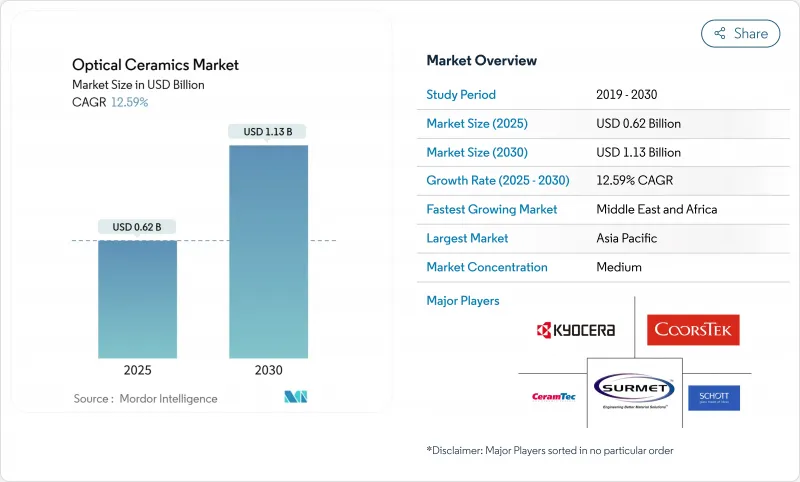

Optical Ceramics - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030)

The optical ceramics market size stood at USD 0.62 billion in 2025 and is forecast to grow to USD 1.13 billion by 2030, registering a 12.59% CAGR.

Strong defense procurement for lighter, infrared-transparent armor, rising use of polycrystalline YAG in surgical lasers, and stricter performance demands in extreme-temperature energy systems supported this momentum. Production innovations such as 'Clean HIP' and vacuum sintering lifted optical clarity while lowering defect rates, encouraging wider use in large-area components. Meanwhile, intellectual-property consolidation and persistently high yield losses for parts above 120 mm diameters limited new entrants, keeping the field moderately concentrated. The intersection of defense, medical, and energy requirements accelerated material transfer across sectors, compressing typical innovation cycles.

Global Optical Ceramics Market Trends and Insights

Rapid Adoption of IR-Transparent Armor in Next-Gen Combat Vehicles

Defense programs integrated ALON and spinel windows that cut weight up to 60% versus laminated glass while maintaining ballistic stop levels, enhancing fuel efficiency, and crew mobility. Components grew to panel sizes of eight square feet, making full-vehicle glazing practical. Machine-learning-guided stacking schemes lowered thickness 22.2% yet raised transmission 42.3%, proving the concept's scalability. Supply contracts from the U.S. Army accelerated the qualification of larger parts and shortened testing cycles. As a result, procurement agencies issued multi-year orders that locked in volume and stabilized pricing.

Surge in UV-LED and Laser-Based Medical Devices Demanding Polycrystalline YAG Optics

Minimally invasive therapies increasingly relied on Ho:YAG and Nd:YAG lasers whose wavelengths are strongly absorbed by water, ensuring precise tissue removal with limited collateral heating. Polycrystalline YAG offered improved thermal conductivity over glass, enabling higher pulse-energy operation and longer component lifetimes. Process innovations delivered 83.7% transmittance at 1064 nm, lifting wall-plug efficiency and facilitating portable surgical platforms well suited to outpatient clinics. Asian contract-device makers expanded production, accelerating regional adoption curves.

Capex-Intensive Hot-Isostatic-Pressing Lines Limiting Emerging-Market Entry

Commercial HIP installations often exceeded USD 15 million, creating high financial thresholds for newcomers. Expertise in pressure-vessel design and controlled-atmosphere operations remained concentrated in mature industrial regions, widening the capability gap. Upgrades such as 'Clean HIP' and 'Steered Cooling' improved performance but also raised capital intensity, reinforcing incumbent advantages.

Other drivers and restraints analyzed in the detailed report include:

- Growth of High-Temperature Gas-Turbine Inspections That Require Sapphire Windows

- Spacecraft Light-Weighting Drives ALON/Spinel Viewports in LEO Satellites

- Yield Losses Above 15% for 120 mm-Diameter Components Keep Unit Costs Uncompetitive vs. Glass

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

YAG retained 30.2% dominance within the optical ceramics market in 2024 through versatility across industrial lasers, scintillators, and sensing optics. Multiple sintering refinements elevated its 1064 nm transmittance, improving beam quality in 10 kW-class laser cutters. ALON posted a 12.3% CAGR by fulfilling aggressive defense and space specifications for lightweight yet ballistic-grade windows. Sapphire maintained energy-sector loyalty thanks to unmatched hardness (Mohs 9) and 2,000 °C thermal stability. Spinel's cubic lattice removed birefringence, supporting airborne imaging. Yttria expanded steadily for plasma-etch chamber liners in semiconductor fabs. Emerging lutetium-based garnets showed promise in next-generation scintillators.

The optical ceramics market size for YAG systems is projected to rise at 11.6% annually, while ALON share gains are forecast to elevate total industry value without materially eroding YAG volumes. Supply chains now routinely dual-source YAG and ALON to tailor mixed-material assemblies, reflecting design optimization rather than strict substitution.

Hot isostatic pressing secured 41.3% revenue in 2024 by producing near-theoretical-density parts with low porosity, essential for ballistic armor and high-power optics. Process refinements like gas-purified chambers raised yield in large panels, reinforcing HIP's economic edge in premium products. Vacuum sintering, however, posted the highest 11.2% CAGR outlook by delivering 70% transmittance in transparent alumina at lower unit energy, appealing to cost-sensitive sectors. Solid-state sintering kept relevance for simpler geometries, while additive manufacturing joined the "Others" category as researchers printed gradient-index elements.

Through 2030, the optical ceramics market share for HIP may slip modestly as vacuum sintering scales, yet overall output from HIP furnaces will climb because larger armor sets drive volume. Hybrid flows that combine vacuum pre-sintering with final HIP densification are under evaluation to balance clarity and cost.

Optical Ceramics Industry is Segmented by Material Type (Yttrium Aluminum Garnet, and More), Fabrication Method (Solid-State Sintering, and More), Product Type (Polycrystalline and Monocrystalline), Application (Transparent Armor and Bullet-Resistant Windows, and More), End-Use Industry (Aerospace and Defense, Healthcare, and More), and Geography (North America, South America, Europe, Asia-Pacific, and Middle East and Africa).

Geography Analysis

Asia-Pacific led the optical ceramics market with 38.3% 2024 revenue thanks to China's rapid battery-pack laser expansion and Japan's focus on light-weighted satellite optics. South Korea and Taiwan added fabs specializing in ceramic flash lamps and sensor windows. Government initiatives such as Japan's Fine Ceramics Roadmap 2050 mapped long-range technology needs.

North America leveraged strong defense spending, particularly U.S. programs upgrading transparent armor and laser systems, maintaining a sizeable share. Collaborative clusters involving Sandia National Laboratories and private industry shortened development cycles by replacing trial-and-error with physics-based modeling. Canada and Mexico contributed specialized production and R&D, securing resiliency in North American supply chains.

The Middle East and Africa recorded the fastest 11.2% CAGR, with Saudi Arabia and the United Arab Emirates funding airborne IR sensor domes built from ALON. Israel's Ceramic and Silicate Institute enabled regional know-how transfer, fostering domestic ballistic-grade armor developments.

Europe retained critical expertise in high-temperature sapphire windows for turbines and precision optics for scientific research. Germany and the United Kingdom drove product innovation, while the Nordic cluster pioneered hydrogen-fired kilns to cut carbon footprints in ceramic processing. South America grew from a small base as Brazil and Argentina introduced sapphire inspection ports in refining and healthcare sectors, leveraging local mineral resources.

- Surmet Corporation

- CoorsTek Inc.

- CeramTec GmbH

- CeraNova Corporation

- Schott AG

- Saint-Gobain S.A.

- Kyocera Corporation

- Murata Manufacturing Co., Ltd.

- Konoshima Chemical Co., Ltd.

- Ceradyne Inc. (3M)

- II-VI Incorporated / Coherent Corp.

- Rubicon Technology Inc.

- Adamant Namiki Precision Jewel Co., Ltd.

- Crystalwise Technology Inc.

- Advanced Ceramics Manufacturing LLC

- AGC Inc.

- Baikowski SA

- Zhongke Jingcheng New Material Co., Ltd.

- Sinoma Advanced Nitride Ceramics Co., Ltd.

- SICCAS High-Tech Materials Co., Ltd.

- American Elements

- Toshima Manufacturing Co., Ltd.

- Ceratec Technical Ceramics BV

- Tera YAG Co., Ltd.

- Precision Ceramics International Ltd.

- Blasch Precision Ceramics Inc.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Rapid adoption of infra-red transparent armor in next-gen combat vehicles

- 4.2.2 Surge in UV-LED and laser-based medical devices demanding polycrystalline YAG optics

- 4.2.3 Growth of high-temperature gas-turbine inspections that require sapphire windows

- 4.2.4 Spacecraft light-weighting drives ALON/spinel viewports in LEO satellites

- 4.2.5 Large-area Li-ion battery pack lasers using ceramic flash lamps

- 4.2.6 Military modernization budgets earmarked for airborne IR sensors with ceramic domes

- 4.3 Market Restraints

- 4.3.1 Capex-intensive hot-isostatic-pressing lines limiting emerging-market entry

- 4.3.2 Yield-losses (>15 %) above 120 mm diameter keep unit costs uncompetitive vs. glass

- 4.3.3 Limited transmittance in the 5-7 µm band constrains long-wave IR adoption

- 4.3.4 IP consolidation-over 120 active U.S. patents block new formulations

- 4.4 Value Chain Analysis

- 4.5 Technological Outlook

- 4.6 Regulatory Outlook

- 4.7 Porter's Five Forces

- 4.7.1 Threat of New Entrants

- 4.7.2 Bargaining Power of Buyers

- 4.7.3 Bargaining Power of Suppliers

- 4.7.4 Threat of Substitutes

- 4.7.5 Competitive Rivalry

- 4.8 Investment and Funding Trends Analysis

- 4.9 Impact of Macroeconomic factors

5 MARKET SIZE AND GROWTH FORECASTS (VALUE)

- 5.1 By Material Type

- 5.1.1 Yttrium Aluminum Garnet (YAG)

- 5.1.2 Aluminum Oxynitride (ALON)

- 5.1.3 Spinel

- 5.1.4 Sapphire

- 5.1.5 Yttria

- 5.1.6 Others

- 5.2 By Fabrication Method

- 5.2.1 Solid-state Sintering

- 5.2.2 Hot Isostatic Pressing (HIP)

- 5.2.3 Vacuum Sintering

- 5.2.4 Others

- 5.3 By Product Type

- 5.3.1 Polycrystalline

- 5.3.2 Monocrystalline

- 5.4 By Application

- 5.4.1 Transparent Armor and Bullet-resistant Windows

- 5.4.2 Sensor and Imaging Optics

- 5.4.3 Laser and Lighting Components

- 5.4.4 Medical Imaging and Diagnostics

- 5.4.5 LEDs and Phosphors

- 5.4.6 Energy and Power Generation Optics

- 5.4.7 Others

- 5.5 By End-Use Industry

- 5.5.1 Aerospace and Defense

- 5.5.2 Healthcare

- 5.5.3 Energy

- 5.5.4 Consumer Electronics

- 5.5.5 Industrial and Manufacturing

- 5.5.6 Research and Instrumentation

- 5.5.7 Others

- 5.6 By Geography

- 5.6.1 North America

- 5.6.1.1 United States

- 5.6.1.2 Canada

- 5.6.1.3 Mexico

- 5.6.2 South America

- 5.6.2.1 Brazil

- 5.6.2.2 Argentina

- 5.6.2.3 Rest of South America

- 5.6.3 Europe

- 5.6.3.1 Germany

- 5.6.3.2 United Kingdom

- 5.6.3.3 France

- 5.6.3.4 Italy

- 5.6.3.5 Nordics (Sweden, Finland, Norway, Denmark)

- 5.6.3.6 Rest of Europe

- 5.6.4 Asia-Pacific

- 5.6.4.1 China

- 5.6.4.2 Japan

- 5.6.4.3 South Korea

- 5.6.4.4 Taiwan

- 5.6.4.5 Rest of Asia-Pacific

- 5.6.5 Middle East and Africa

- 5.6.5.1 Middle East

- 5.6.5.1.1 Saudi Arabia

- 5.6.5.1.2 United Arab Emirates

- 5.6.5.1.3 Turkey

- 5.6.5.1.4 Rest of Middle East

- 5.6.5.2 Africa

- 5.6.5.2.1 South Africa

- 5.6.5.2.2 Nigeria

- 5.6.5.2.3 Rest of Africa

- 5.6.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles {(includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)}

- 6.4.1 Surmet Corporation

- 6.4.2 CoorsTek Inc.

- 6.4.3 CeramTec GmbH

- 6.4.4 CeraNova Corporation

- 6.4.5 Schott AG

- 6.4.6 Saint-Gobain S.A.

- 6.4.7 Kyocera Corporation

- 6.4.8 Murata Manufacturing Co., Ltd.

- 6.4.9 Konoshima Chemical Co., Ltd.

- 6.4.10 Ceradyne Inc. (3M)

- 6.4.11 II-VI Incorporated / Coherent Corp.

- 6.4.12 Rubicon Technology Inc.

- 6.4.13 Adamant Namiki Precision Jewel Co., Ltd.

- 6.4.14 Crystalwise Technology Inc.

- 6.4.15 Advanced Ceramics Manufacturing LLC

- 6.4.16 AGC Inc.

- 6.4.17 Baikowski SA

- 6.4.18 Zhongke Jingcheng New Material Co., Ltd.

- 6.4.19 Sinoma Advanced Nitride Ceramics Co., Ltd.

- 6.4.20 SICCAS High-Tech Materials Co., Ltd.

- 6.4.21 American Elements

- 6.4.22 Toshima Manufacturing Co., Ltd.

- 6.4.23 Ceratec Technical Ceramics BV

- 6.4.24 Tera YAG Co., Ltd.

- 6.4.25 Precision Ceramics International Ltd.

- 6.4.26 Blasch Precision Ceramics Inc.

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-space and Unmet-need Assessment