PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1850977

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1850977

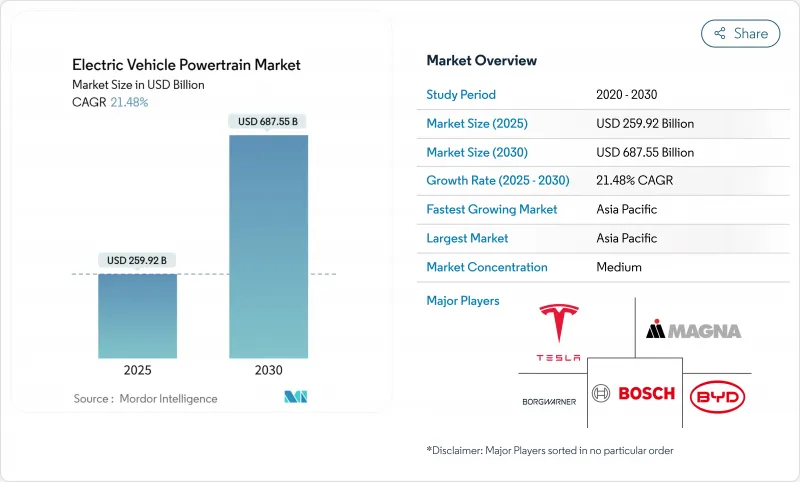

Electric Vehicle Powertrain - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030)

The electric vehicle powertrain market size stands at USD 259.92 billion in 2025 and is projected to reach USD 687.55 billion by 2030, translating into a 21.48% CAGR.

Accelerated phase-outs of combustion engines, steady battery-pack price drops to USD 115 per kWh, and rapid adoption of 800-V architectures propel this expansion. Wide-bandgap semiconductors push inverter efficiency above 96%, while cell-to-pack engineering trims both weight and cost. Asia-Pacific leads the supply chain with integrated battery, motor, and electronics clusters, even as North America and Europe deploy powerful localization incentives.

Global Electric Vehicle Powertrain Market Trends and Insights

Surging Global EV Sales Volumes

Electric-vehicle registrations crossed 17 million units in 2024, lifting plug-in share above 20% of world light-vehicle sales and boosting demand for motors, inverters and battery packs that are three times more semiconductor-intensive than comparable combustion drivetrains. China's 11 million-unit tally alone reshaped volume planning for every supplier, while Europe's incentives preserved double-digit growth despite macro headwinds. Each new EV requires around 80 kg of high-grade copper and significant rare-earth content, so component makers have ramped long-term supply contracts in tandem with capacity additions. Battery demand topped 1 TWh in 2024; with almost half now lithium iron phosphate, OEMs are redesigning pack formats to exploit the chemistry's cost edge. Volume scale pushes total system costs down, yet intensifies supplier competition for long-run contracts that lock in price visibility through 2030.

Stringent Tail-Pipe & ZEV Regulations

The European Union will prohibit sales of new combustion cars by 2035, and California's Advanced Clean Cars II rule enforces the same deadline in the United States . Similar zero-emission mandates cascade across Canada, South Korea and several Latin American markets, stripping automakers of any remaining latitude to delay electrification. Compliance costs for legacy internal-combustion platforms are now higher than the incremental spend required to launch a modern e-powertrain, redirecting R&D budgets toward integrated e-axle solutions and next-generation inverters. Suppliers already proficient in clean-sheet electric designs therefore gain bargaining power in platform sourcing rounds, because OEMs must compress traditional five-year cycles into three-year refreshes to stay ahead of regulation.

Public DC-Fast-Charging Gap in Emerging Markets

Twenty-two developing nations together host barely 14,100 public chargers, a level that deters fleet electrification and weakens consumer confidence . Powertrains tuned for 400-V networks offer sufficient range but miss the full efficiency upside of 800-V hardware that requires higher-powered chargers. The investment deficit stems from fragile utility grids and limited private-sector financing. Vehicle makers must therefore tailor drivetrain configurations to local infrastructure realities, often opting for larger battery packs or onboard generators, which inflate curb weight and blunt energy efficiency gains.

Other drivers and restraints analyzed in the detailed report include:

- Rapid Cost Decline in High-Nickel Battery Chemistries

- OEM Shift to 800-Volt Architectures

- Critical-Mineral Supply Volatility

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Battery packs contributed 38.32% revenue in 2024, making them the single largest element of the electric vehicle powertrain market, yet the power-electronics block is growing faster at 29.42% CAGR as wide-bandgap devices unlock higher switching speeds. Average pack capacity rose to 62 kWh in 2024 for passenger cars, a level that pushes demand for improved thermal paths and integrated structural designs. Silicon-carbide inverters now reach 97% peak efficiency, slicing highway power losses by double digits and extending vehicle range without adding battery mass. Drive-unit suppliers layer permanent-magnet motors with hairpin windings and compact reduction gears, allowing finer torque control while shaving drivetrain noise. Higher-value content per vehicle spurs a wave of mergers among inverter, motor, and gearbox suppliers that pursue e-axle bundles promising double-digit margins. Concurrently, thermal-management specialists introduce multi-channel cold-plate assemblies that cool battery modules and power electronics from a single loop, saving 15% system weight.

Integrated DC-DC converters share common cooling plates with on-board chargers, shrinking under-hood space requirements in compact crossover models. Motor suppliers increase permanent-magnet free designs that use copper-rotor induction or switched-reluctance topologies to reduce dependence on dysprosium and neodymium. Tier-1 giants announce multi-year supply accords with domestic and Chinese chip fabricators to secure next-generation 1,200-V SiC dies for 2028 vehicle launches. As suppliers vertically integrate, intellectual-property battles intensify around gate-drive algorithms and heat-spreader layouts that deliver the last two points of efficiency.

Battery electric vehicles captured 71.24% of share in 2024 and are forecast to clip along at 24.80% CAGR, confirming the market's pivot away from plug-in hybrids and range-extended architectures. Dedicated BEV skateboard platforms shave 30 kg of wiring and simplify assembly by integrating the battery pack as a stressed chassis member. Regulatory credit regimes in China, the European Union, and twelve U.S. states give carmakers an effective price advantage of USD 3,000-USD 5,000 per BEV compared with hybrid equivalents, widening BEV adoption. Fast-charger build-outs across Germany, France, and Norway raise public confidence, enabling compact-segment BEVs with smaller packs, which in turn shift component demand toward higher power-density inverters. Automakers employ cell-to-pack and cell-to-chassis strategies to strip module casings and increase volumetric energy density by up to 20%, indirectly boosting thermal-management spending.

Fuel-cell electric vehicles remain below 1% of unit volume yet draw significant R&D within heavy-duty logistics corridors in California, Japan, and South Korea, where hydrogen fueling networks cluster. Over the forecast horizon, BEVs siphon share from mild-hybrid and conventional powertrains in urban buses, municipal fleets and ride-hail operators that optimize around lower total cost of ownership. Component suppliers respond with scalable inverter families that toggle between 400 V and 800 V to serve both BEV and PHEV platforms without redesign, while software-defined powertrain controllers handle dual traction sources for transitional architectures.

The Electric Vehicle Powertrain Market Report is Segmented by Component (Battery Pack, Power Electronics, and More), Propulsion Type (Battery Electric Vehicle (BEV) and More), Vehicle Class (Passenger Cars, Light Commercial Vehicles, and More), Voltage Architecture (800 V Systems and More), Sales Channel (OEM-Fitted Powertrains and More) and Geography. The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Asia-Pacific commanded 57.66% of the electric vehicle powertrain market in 2024 and is projected to grow at 26.64% CAGR through 2030 as China exports value-priced electric crossovers to Latin America and Eastern Europe. Chinese battery champions held 37.9% global share, giving the region scale advantages that drive pack prices toward USD 90 per kWh. India's Production-Linked Incentive program disburses subsidies equal to up to 15% of domestic value added, spurring local assembly of motors, controllers and lithium iron phosphate cells. Japan leverages power-device know-how to ship SiC MOSFETs worldwide, while South Korea supplies high-nickel NCM cathodes to European gigafactories.

North America trails in volume but benefits from USD 250 billion of announced investment across batteries, motors and inverter fabs since mid-2022. The Inflation Reduction Act's clean-vehicle credit requires 60% North-American battery-component value in 2025, prompting Korean and Japanese suppliers to build cathode-active-material plants in Kentucky, Tennessee and Quebec. Mexico rises as a low-cost e-motor hub exporting to both U.S. and European plants. Canada's mineral wealth underpins cathode refining ventures that aim to supply half of the continent's lithium needs by 2030.

Europe wrestles with uneven momentum: Germany and France sustain double-digit BEV penetration, yet the United Kingdom saw a 20% retreat in electric-vehicle output during 2024 due to stalled incentives and battery-capacity shortfalls. The European Union's Fit-for-55 package and CO2 fleet mandates keep long-term demand intact, driving suppliers such as ZF to open an 800 V testing lab near Birmingham in October 2024. Eastern European countries pitch competitive labor costs to attract final-assembly plants, filling the gap left by ICE component contraction. Meanwhile, Middle East and Africa remain nascent but post 40% annual growth from a small base, aided by Gulf sovereign-wealth funds that bankroll battery-cell manufacturing in Saudi Arabia and the United Arab Emirates.

- Tesla, Inc.

- BYD Co. Ltd.

- Bosch Mobility (Robert Bosch GmbH)

- Magna International Inc.

- BorgWarner Inc.

- ZF Friedrichshafen AG

- Dana Incorporated

- GKN Automotive

- Hitachi Astemo, Ltd.

- Mitsubishi Electric Corporation

- AVL List GmbH

- Cummins Inc.

- Siemens AG (eMobility)

- Nidec Corporation

- Continental AG

- Valeo SA

- Vitesco Technologies Group AG

- AISIN Corporation

- Denso Corporation

- Schaeffler AG

- Hyundai Mobis Co., Ltd.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions & Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Surging global EV sales volumes

- 4.2.2 Stringent tail-pipe & ZEV regulations

- 4.2.3 Rapid cost decline in high-nickel battery chemistries

- 4.2.4 OEM shift to 800-volt architectures

- 4.2.5 Localization incentives for e-drive manufacturing

- 4.2.6 Tier-1 vertical integration of e-Axle bundles

- 4.3 Market Restraints

- 4.3.1 Public DC-fast-charging gap in emerging markets

- 4.3.2 Critical-mineral supply volatility

- 4.3.3 Thermal-runaway safety & warranty-cost exposure

- 4.3.4 High-voltage talent shortage in manufacturing hubs

- 4.4 Value / Supply-Chain Analysis

- 4.5 Regulatory Landscape

- 4.6 Technological Outlook

- 4.7 Porter's Five Forces

- 4.7.1 Threat of New Entrants

- 4.7.2 Bargaining Power of Buyers

- 4.7.3 Bargaining Power of Suppliers

- 4.7.4 Threat of Substitutes

- 4.7.5 Intensity of Competitive Rivalry

5 Market Size & Growth Forecasts (Value, USD)

- 5.1 By Component

- 5.1.1 Electric Motors

- 5.1.1.1 Permanent-Magnet Synchronous

- 5.1.1.2 Induction

- 5.1.1.3 Switched-Reluctance

- 5.1.2 Transmission / e-Axle Systems

- 5.1.2.1 Single-Speed

- 5.1.2.2 Multi-Speed

- 5.1.3 Power Electronics

- 5.1.3.1 Inverters

- 5.1.3.2 DC-DC Converters

- 5.1.3.3 On-Board Chargers

- 5.1.4 Battery Pack

- 5.1.5 Thermal Management Systems

- 5.1.6 High-Voltage Cabling & Controllers

- 5.1.1 Electric Motors

- 5.2 By Propulsion Type

- 5.2.1 Battery Electric Vehicle (BEV)

- 5.2.2 Plug-in Hybrid Electric Vehicle (PHEV)

- 5.2.3 Fuel-Cell Electric Vehicle (FCEV)

- 5.3 By Vehicle Class

- 5.3.1 Passenger Cars

- 5.3.2 Light Commercial Vehicles

- 5.3.3 Heavy Commercial Vehicles

- 5.3.4 Two and Three-Wheelers

- 5.3.5 Off-Highway Vehicles

- 5.4 By Voltage Architecture

- 5.4.1 Less than equal to 400 V Systems

- 5.4.2 800 V Systems

- 5.4.3 Above 800 V Systems

- 5.5 By Sales Channel

- 5.5.1 OEM-Fitted Powertrains

- 5.5.2 Aftermarket Retrofit Kits

- 5.6 By Geography

- 5.6.1 North America

- 5.6.1.1 United States

- 5.6.1.2 Canada

- 5.6.1.3 Rest of North America

- 5.6.2 South America

- 5.6.2.1 Brazil

- 5.6.2.2 Argentina

- 5.6.2.3 Rest of South America

- 5.6.3 Europe

- 5.6.3.1 Germany

- 5.6.3.2 United Kingdom

- 5.6.3.3 France

- 5.6.3.4 Italy

- 5.6.3.5 Spain

- 5.6.3.6 Netherlands

- 5.6.3.7 Rest of Europe

- 5.6.4 Asia-Pacific

- 5.6.4.1 China

- 5.6.4.2 Japan

- 5.6.4.3 India

- 5.6.4.4 South Korea

- 5.6.4.5 Thailand

- 5.6.4.6 Vietnam

- 5.6.4.7 Rest of Asia-Pacific

- 5.6.5 Middle East and Africa

- 5.6.5.1 Saudi Arabia

- 5.6.5.2 United Arab Emirates

- 5.6.5.3 Turkey

- 5.6.5.4 South Africa

- 5.6.5.5 Egypt

- 5.6.5.6 Rest of Middle East and Africa

- 5.6.1 North America

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global-level Overview, Market-level Overview, Core Segments, Financials, Strategic Information, Market Rank/Share, Products & Services, Recent Developments)

- 6.4.1 Tesla, Inc.

- 6.4.2 BYD Co. Ltd.

- 6.4.3 Bosch Mobility (Robert Bosch GmbH)

- 6.4.4 Magna International Inc.

- 6.4.5 BorgWarner Inc.

- 6.4.6 ZF Friedrichshafen AG

- 6.4.7 Dana Incorporated

- 6.4.8 GKN Automotive

- 6.4.9 Hitachi Astemo, Ltd.

- 6.4.10 Mitsubishi Electric Corporation

- 6.4.11 AVL List GmbH

- 6.4.12 Cummins Inc.

- 6.4.13 Siemens AG (eMobility)

- 6.4.14 Nidec Corporation

- 6.4.15 Continental AG

- 6.4.16 Valeo SA

- 6.4.17 Vitesco Technologies Group AG

- 6.4.18 AISIN Corporation

- 6.4.19 Denso Corporation

- 6.4.20 Schaeffler AG

- 6.4.21 Hyundai Mobis Co., Ltd.

7 Market Opportunities & Future Outlook

- 7.1 White-Space & Unmet-Need Assessment