PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1851772

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1851772

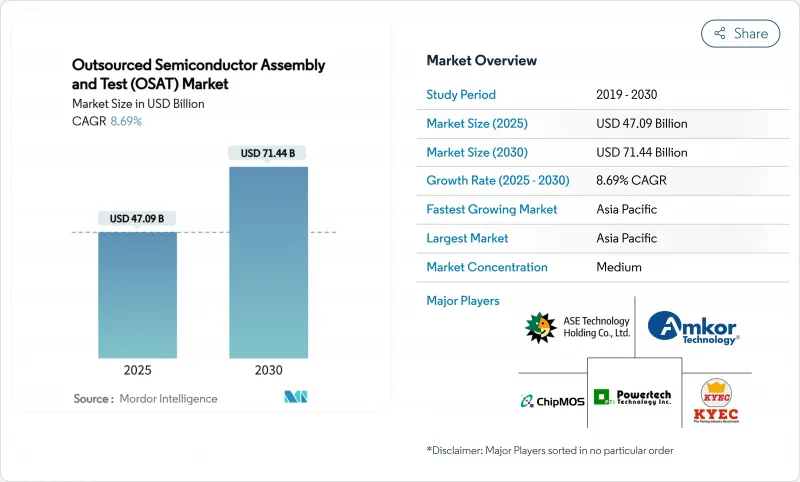

Outsourced Semiconductor Assembly And Test (OSAT) - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030)

The outsourced semiconductor assembly and test market size reached USD 47.09 billion in 2025 and is forecast to attain USD 71.44 billion by 2030, advancing at an 8.69% CAGR.

Sustained progress in artificial intelligence, high-performance computing, and automotive electrification raised demand for advanced packages and safety-critical test flows, thereby widening the total addressable opportunity for specialized backend service providers. Asia-Pacific suppliers preserved pricing leverage owing to mature ecosystems, yet policy-driven capacity build-outs in North America and Europe began to reshape global supply allocation. Hybrid chiplet architectures elevated the importance of heterogeneous integration, motivating strategic investments in fan-out wafer-level and 2.5D/3D platforms. Meanwhile, tighter trade controls and sustainability mandates encouraged customers to shift part of the workload to geographically diversified sites that can demonstrate lower energy use per unit throughput. As foundry capacity remained strained, fab-lite semiconductor companies continued to outsource backend steps, reinforcing the structural relevance of the outsourced semiconductor assembly and test market in the next planning cycle.

Global Outsourced Semiconductor Assembly And Test (OSAT) Market Trends and Insights

Soaring Semiconductor Content Per Vehicle

Automotive OEMs transitioned toward software-defined platforms, lifting semiconductor bill-of-materials per car and intensifying demand for high-reliability packages. Volkswagen Group's traction inverter partnership with onsemi highlighted the rising adoption of silicon carbide devices that need thermally robust power packages.Imec's Automotive Chiplet Program, supported by ASE, BMW, and Bosch, illustrated cross-value-chain alignment on standardized chiplet packaging for functional safety compliance. OSAT providers that qualify to AEC-Q100 and ISO 26262, therefore, captured new design wins and secured multiyear capacity reservations with electric-vehicle suppliers.

5G-Led Demand for Advanced RF Packages

Commercial 5G base-station roll-outs moved the radio front-end into millimetre-wave territory, necessitating low-loss substrates, conformal shielding, and compact SiP footprints. Finwave Semiconductor's E-mode MISHEMT integration at GlobalFoundries signalled commercial deployment of novel gallium-nitride devices that require specialised RF packaging, with mass qualification targeted for 2026. The pipeline for 6G testbeds already incorporates co-packaged optics, urging OSAT firms to expand mixed-signal assembly capabilities and advanced thermal solutions.

Vertical Integration by Leading Foundries and IDMs

TSMC's Wafer Manufacturing 2.0 strategy integrated packaging and testing flows, offering turnkey services that reduced addressable volume for stand-alone OSAT companies. Samsung pursued a similar path, while Intel grew its foundry services to include advanced interposers. These moves compressed third-party share in high-margin segments and obliged OSAT firms to double down on niches such as automotive safety or photonics.

Other drivers and restraints analyzed in the detailed report include:

- AI/HPC Chiplet Architectures Needing Heterogeneous Integration

- Foundry Capacity Shortages Driving Fab-Lite Outsourcing

- Cap-Ex Intensity and Long Equipment Lead-Times

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Testing captured a 10.8% CAGR forecast for 2025-2030, a pace outstripping packaging's expansion yet starting from a smaller base. AI and high-performance computing designs demanded system-level test coverage that verifies chiplet interconnect latency, dynamic thermal throttling, and deep-learning workload performance under varied voltages. The outsourced semiconductor assembly and test market responded by integrating adaptive machine-learning algorithms in automatic test equipment, cutting test time while improving fault isolation.

Packaging retained 77.5% of 2024 revenue, but its composition evolved toward fan-out panel-level, 2.5D interposer, and co-packaged optics lines. As customers consolidated suppliers, OSAT groups bundled turnkey offerings that merge fixture design, final test, and logistics. Advantest secured its sixth consecutive leadership in assembly test equipment after adding AI-enabled analytics to its V93000 series.

Ball grid array technology maintained a 24.3% share in 2024 by serving mainstream consumer and industrial platforms that value mechanical robustness. However, fan-out wafer-level packages expanded at 11.5% CAGR as mobile processors and AI accelerators transitioned to high-density redistribution layers. This trend strengthened the outsourced semiconductor assembly and test market because only a limited pool of vendors can process larger panel formats without yield drift.

ASE's USD 200 million panel-level expansion to 310 mm X 310 mm glass panels illustrated a cap-ex commitment toward cost-effective, large-area builds. Through-silicon-via and through-glass-via variants proliferated in high-bandwidth memory stacks. FC-BGA substrates benefited from advanced node adoption, bridging the gap between organic laminates and silicon interposers for networking ASICs.

Outsourced Semiconductor Assembly and Test (OSAT) Market is Segmented by Service Type (Packaging, and Testing), Packaging Type (Ball Grid Array, Chip-Scale Package, and More), Application (Communication, Consumer Electronics, Automotive, Computing and Networking, and More), Technology Node (>=28 Nm, 16/14 Nm, 10/7 Nm, and More), and Geography (North America, South America, Europe, Asia-Pacific, and Middle East and Africa).

Geography Analysis

Asia-Pacific retained 73.5% share of outsourced semiconductor assembly and test market revenue in 2024 and posted a 9.6% CAGR outlook through 2030. Taiwan, China, and South Korea anchored the cluster owing to proximity to foundries and substrate makers, yet escalating trade frictions prompted diversification into Malaysia, Vietnam, and the Philippines. India accelerated incentive programmes, endorsing Kaynes Technology's USD 413 million plant in Gujarat and Tata Electronics' USD 3 billion Assam package-test complex.

North America regained strategic weight following the CHIPS Act funding. Amkor broke ground on an advanced packaging facility in Arizona designed to supply domestic automotive and AI customers. Texas Instruments earmarked USD 60 billion for multiple wafer fabs and corresponding backend capacity, while SkyWater's USD 93 million acquisition of Infineon's Austin fab added sovereign redundancy.

Europe moved from niche R&D toward scaled production. Silicon Box obtained EU approval for a EUR 1.3 billion (USD 1.47 billion) panel-level plant in Italy, targeting >100 million SiP units per year. Thales, Radiall, and Foxconn explored a French OSAT alliance to serve defence and aeronautics users. Onsemi committed USD 2 billion to a silicon-carbide line in the Czech Republic, assuring local supply for e-mobility projects. The Middle East and Africa remained an emerging frontier, with Israel and the UAE assessing policy frameworks to attract backend investors.

- ASE Technology Holding Co., Ltd.

- Amkor Technology, Inc.

- Jiangsu Changjiang Electronics Technology Co., Ltd.

- Siliconware Precision Industries Co., Ltd.

- Powertech Technology Inc.

- King Yuan Electronics Co., Ltd.

- Tongfu Microelectronics Co., Ltd.

- Tianshui Huatian Technology Co., Ltd.

- UTAC Holdings Ltd.

- Unisem (M) Berhad

- Hana Micron Inc.

- ChipMOS Technologies Inc.

- Formosa Advanced Technologies Co., Ltd.

- Chipbond Technology Corporation

- Lingsen Precision Industries, Ltd.

- Suchi Semicon Pvt. Ltd.

- Nepes Corporation

- Silicon Box Pte. Ltd.

- Shinko Electric Industries Co., Ltd.

- Carsem (M) Sdn. Bhd.

- SFA Semicon Co., Ltd.

- Stats ChipPAC Pte. Ltd.

- Orient Semiconductor Electronics, Ltd.

- Integra Technologies LLC

- Anam Semiconductor Inc.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Soaring semiconductor content per vehicle

- 4.2.2 5G-led demand for advanced RF packages

- 4.2.3 AI/HPC chiplet architectures needing heterogeneous integration

- 4.2.4 Foundry capacity shortages driving fab-lite outsourcing

- 4.2.5 U.S. CHIPS and EU Chips Acts incentivising local OSAT build-out

- 4.2.6 Sustainability mandates pushing wafer-level fan-out adoption

- 4.3 Market Restraints

- 4.3.1 Vertical integration by leading foundries and IDMs

- 4.3.2 Cap-ex intensity and long equipment lead-times

- 4.3.3 Geopolitical export controls on advanced tools

- 4.3.4 Skilled-labour shortages in advanced packaging engineering

- 4.4 Value Chain Analysis

- 4.5 Regulatory Landscape

- 4.6 Technological Outlook

- 4.7 Impact of Macroeconomic Factors

- 4.8 Porter's Five Forces Analysis

- 4.8.1 Bargaining Power of Suppliers

- 4.8.2 Bargaining Power of Buyers

- 4.8.3 Threat of New Entrants

- 4.8.4 Threat of Substitutes

- 4.8.5 Intensity of Competitive Rivalry

5 MARKET SIZE AND GROWTH FORECASTS (VALUE)

- 5.1 By Service Type

- 5.1.1 Packaging

- 5.1.2 Testing

- 5.2 By Packaging Type

- 5.2.1 Ball Grid Array (BGA)

- 5.2.2 Chip-Scale Package (CSP)

- 5.2.3 Quad Flat / Dual-Inline (QFP/DIP)

- 5.2.4 Multi-Chip Module (MCM)

- 5.2.5 Wafer-Level Packaging (WLP)

- 5.2.6 Fan-Out Packaging (FO-WLP / FO-BGA)

- 5.2.7 System-in-Package (SiP)

- 5.2.8 Through-Silicon Via (2.5D/3D TSV)

- 5.2.9 Flip-Chip (FC-BGA / FC-CSP)

- 5.3 By Application

- 5.3.1 Communication

- 5.3.2 Consumer Electronics

- 5.3.3 Automotive

- 5.3.4 Computing and Networking

- 5.3.5 Industrial

- 5.3.6 Other Applications

- 5.4 By Technology Node

- 5.4.1 >=28 nm

- 5.4.2 16/14 nm

- 5.4.3 10/7 nm

- 5.4.4 5 nm and below

- 5.4.5 Legacy (90-65 nm)

- 5.5 By Geography

- 5.5.1 North America

- 5.5.1.1 United States

- 5.5.1.2 Canada

- 5.5.1.3 Mexico

- 5.5.2 South America

- 5.5.2.1 Brazil

- 5.5.2.2 Argentina

- 5.5.2.3 Rest of South America

- 5.5.3 Europe

- 5.5.3.1 Germany

- 5.5.3.2 France

- 5.5.3.3 United Kingdom

- 5.5.3.4 Italy

- 5.5.3.5 Netherlands

- 5.5.3.6 Russia

- 5.5.3.7 Rest of Europe

- 5.5.4 Asia-Pacific

- 5.5.4.1 China

- 5.5.4.2 Taiwan

- 5.5.4.3 South Korea

- 5.5.4.4 Japan

- 5.5.4.5 Singapore

- 5.5.4.6 Malaysia

- 5.5.4.7 India

- 5.5.4.8 Rest of Asia-Pacific

- 5.5.5 Middle East and Africa

- 5.5.5.1 Middle East

- 5.5.5.1.1 Israel

- 5.5.5.1.2 United Arab Emirates

- 5.5.5.1.3 Saudi Arabia

- 5.5.5.1.4 Turkey

- 5.5.5.1.5 Rest of Middle East

- 5.5.5.2 Africa

- 5.5.5.2.1 South Africa

- 5.5.5.2.2 Nigeria

- 5.5.5.2.3 Rest of Africa

- 5.5.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level Overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share, Products and Services, Recent Developments)

- 6.4.1 ASE Technology Holding Co., Ltd.

- 6.4.2 Amkor Technology, Inc.

- 6.4.3 Jiangsu Changjiang Electronics Technology Co., Ltd.

- 6.4.4 Siliconware Precision Industries Co., Ltd.

- 6.4.5 Powertech Technology Inc.

- 6.4.6 King Yuan Electronics Co., Ltd.

- 6.4.7 Tongfu Microelectronics Co., Ltd.

- 6.4.8 Tianshui Huatian Technology Co., Ltd.

- 6.4.9 UTAC Holdings Ltd.

- 6.4.10 Unisem (M) Berhad

- 6.4.11 Hana Micron Inc.

- 6.4.12 ChipMOS Technologies Inc.

- 6.4.13 Formosa Advanced Technologies Co., Ltd.

- 6.4.14 Chipbond Technology Corporation

- 6.4.15 Lingsen Precision Industries, Ltd.

- 6.4.16 Suchi Semicon Pvt. Ltd.

- 6.4.17 Nepes Corporation

- 6.4.18 Silicon Box Pte. Ltd.

- 6.4.19 Shinko Electric Industries Co., Ltd.

- 6.4.20 Carsem (M) Sdn. Bhd.

- 6.4.21 SFA Semicon Co., Ltd.

- 6.4.22 Stats ChipPAC Pte. Ltd.

- 6.4.23 Orient Semiconductor Electronics, Ltd.

- 6.4.24 Integra Technologies LLC

- 6.4.25 Anam Semiconductor Inc.

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-space and Unmet-Need Assessment