PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1906082

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1906082

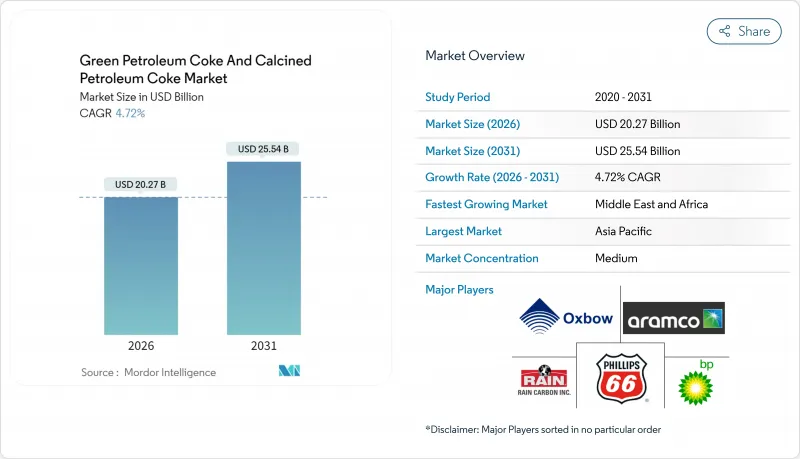

Green Petroleum Coke And Calcined Petroleum Coke - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2026 - 2031)

The Green Petroleum Coke And Calcined Petroleum Coke Market was valued at USD 19.36 billion in 2025 and estimated to grow from USD 20.27 billion in 2026 to reach USD 25.54 billion by 2031, at a CAGR of 4.72% during the forecast period (2026-2031).

This steady climb reflects delayed coking investments in the Middle East and Asia-Pacific, tightening sulfur limits in China's anode sector, and widening price spreads between low-sulfur and high-sulfur grades. The Asia-Pacific region retains its demand leadership as aluminium smelters and cement plants absorb growing volumes, while new complexes in Saudi Arabia, the United Arab Emirates, and Nigeria increase exportable supply. Environmental regulations in the European Union and North America are reshaping trade lanes, favoring low-emission origins and vertically integrated suppliers. Competitive dynamics reveal refiners tightening their control over green coke feedstock, independent calciners adding capacity despite margin pressure, and specialty grades, such as ultra-low-sulfur coke, capturing premiums for use in lithium-ion battery anodes.

Global Green Petroleum Coke And Calcined Petroleum Coke Market Trends and Insights

Rising Aluminium Smelting Capacity Expansions

In 2024, the global aluminium output necessitated a significant amount of calcined coke. This demand solidifies a structural floor for premium low-sulfur feedstocks. China, the dominant player, consumed a substantial share. However, as power prices decline and new smelters secure long-term LNG contracts, regional smelter growth is pivoting towards India and the Gulf Cooperation Council states. While new calcining projects in Oman and Brazil heighten global competition, many of these facilities still rely on imported low-sulfur green coke from other regions. Tightening quality standards-such as stricter sulfur caps and vanadium restrictions-benefit integrated refiners who can manage streams internally, thereby squeezing margins for high-sulfur producers. Additionally, smelters are now incorporating scope-1 CO2 intensity ceilings into long-term offtake contracts, further elevating the value of low-emission coke grades.

Fuel-Grade Petcoke Cost Advantage Over Coal in Cement Kilns

In 2025, high-sulfur petcoke maintained a significant discount to coal, sustaining kiln demand despite volatile freight. India reduced import duties, while Turkey removed tariffs on U.S. supplies, broadening accessible demand pools. Forward trends indicate that discounts are narrowing during hurricane season, prompting some producers to secure multi-quarter contracts. Decarbonization roadmaps envision a transitional kiln fuel split of petcoke, coal, and biomass by 2050, preserving a medium-term niche for petcoke even as carbon costs rise. Covered storage mandates at Indian and U.S. ports add handling costs, yet the net fuel advantage over coal remains intact under most price scenarios.

Stricter SOx/PM Limits and Carbon Border Adjustment in European Union

The EU Carbon Border Adjustment Mechanism has entered transitional reporting and will impose fees in the coming years, with residual products, such as petcoke, positioned for phased inclusion in the future. Importers must disclose direct and indirect emissions, as well as the carbon prices in their origin countries, narrowing the cost advantages for high-sulfur coke. In the United States, stand-alone calciners emitted significant levels of SO2, yet many still lack scrubbers. If federal limits tighten to match EU standards, retrofits could add fixed costs, reshaping trade toward lower-emission plants.

Other drivers and restraints analyzed in the detailed report include:

- Capacity Build-Out of Delayed Coking Units in Middle-East Refineries

- Ultra-Low-Sulfur Coke for Li-Ion Battery Anodes

- Community Opposition to Petcoke Handling in Port Cities

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Fuel-grade material held 60.95% of the Green Petroleum Coke and Calcined Petroleum Coke Market share in 2025, driven by demand from cement kilns and boilers. Prices are still undercutting coal, although the discount has narrowed against historical norms. Many refineries optimize delayed-coker operating severity to favor fuel-grade volumes, maximizing vacuum resid destruction over quality. The green petroleum coke and calcined petcoke market size for fuel-grade supply is expected to grow steadily during the forecast period.

Calcined coke is advancing at a 5.76% CAGR, stimulated by aluminium anode expansions and specialty demands in titanium dioxide, recarburizers, and graphite electrodes. Plant additions in India, Oman, and China could significantly increase global calcined capacity in the coming years. Yet sulfur tightening below 3% crimps effective feedstock, prompting refiners to apply desulfurizing additives and blend fit-for-purpose streams. The segment captures higher margins owing to vibrated bulk-density premiums and low metal impurity thresholds, although oversupply risk in the near future may pressure spot differentials.

The Green Petroleum Coke and Calcined Petroleum Coke Market Report is Segmented by Type (Fuel Grade and Calcined Coke), Application (Green Petroleum Coke: Aluminum, Fuel, Iron and Steel, Silicon Metal, and Others; Calcined Petroleum Coke: Aluminum, Titanium Dioxide, Re-Carburizing Market, and Others), and Geography (Asia-Pacific, North America, Europe, and More). The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Asia-Pacific captured 47.90% revenue share in 2025, anchored by China's substantial petcoke requirement and aluminium prebake capacity. Imports of uncalcined coke increased year over year, with the United States, Russia, and Saudi Arabia supplying the bulk. Japan and South Korea maintain advanced needle coke technology, while ASEAN cement kilns substitute high-sulfur pet coke for coal to manage costs amid volatile LNG prices.

The Middle East and Africa Green Petroleum Coke and Calcined Petroleum Coke Market is projected to grow at a 5.62% CAGR through 2031, driven by the introduction of new coking trains in Saudi Arabia, the UAE, Kuwait, Egypt, and Nigeria, which is expected to increase feedstock availability. Integrated complexes such as Dangote's refinery are moving beyond light-product exports to monetize heavy residue streams. Proximity to aluminium smelters in Bahrain and Oman shortens supply chains, while lower sulfur in Arabian medium crudes enables premium calcined output.

North America remains the largest exporter, accounting for a significant portion of the global green coke production. However, port-side environmental constraints on the U.S. West Coast and Gulf Coast increase logistics costs, prompting some refiners to enter long-term contracts for Asia-bound shipments delivered ex-ship. Europe's declining refinery slate curbs indigenous supply even as demand for low-sulfur CPC persists; EU CBAM fees, starting from 2026, will likely shift buyers toward Middle Eastern streams with lower scope-1 emissions profiles.

- Aluminium Bahrain B.S.C. (Alba)

- BP p.l.c

- Chevron Corp

- China Petroleum & Chemical Corporation (Sinopec)

- CNOOC Limited

- ELSID SA

- Exxon Mobil Corp

- Indian Oil Corporation

- Maniayargroup

- Marathon Petroleum

- Numaligarh Refinery Limited

- Oxbow Corporation

- Petrocoque

- Phillips 66 Company

- Rain Carbon Inc.

- Reliance Industries Ltd

- Rio Tinto

- Saudi Aramco

- Saudi Calcined Petroleum Coke Company (SCPC)

- Valero Energy Corp

- Zhenjiang Coking And Gas Group Co. Ltd

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Rising aluminium smelting capacity expansions

- 4.2.2 Fuel-grade petcoke cost advantage over coal in cement kilns

- 4.2.3 Capacity build-out of delayed coking units in Middle-East refineries

- 4.2.4 Needle-grade CPC demand from graphite electrodes for EAF steel

- 4.2.5 Ultra-low-sulfur coke for Li-ion battery anodes

- 4.3 Market Restraints

- 4.3.1 Volatile crude-oil crack spreads impacting GPC availability

- 4.3.2 Stricter SOx/PM limits and Carbon Border Adjustment in European Union

- 4.3.3 Community opposition to petcoke handling in port cities

- 4.4 Value Chain Analysis

- 4.5 Porter's Five Forces

- 4.5.1 Bargaining Power of Suppliers

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Threat of New Entrants

- 4.5.4 Threat of Substitutes

- 4.5.5 Degree of Competition

5 Market Size and Growth Forecasts (Value)

- 5.1 Type

- 5.1.1 Fuel Grade

- 5.1.2 Calcined Coke

- 5.2 Application

- 5.2.1 Green Petroleum Coke

- 5.2.1.1 Aluminum

- 5.2.1.2 Fuel

- 5.2.1.3 Iron and steel

- 5.2.1.4 Silicon Metal

- 5.2.1.5 Others (Bricks, Glass, Carbon Products, etc)

- 5.2.2 Calcined Petroleum Coke

- 5.2.2.1 Aluminum

- 5.2.2.2 Titanium Dioxide

- 5.2.2.3 Re-carburizing Market

- 5.2.2.4 Others (Needle Coke, Carbon Products, etc)

- 5.2.1 Green Petroleum Coke

- 5.3 By Geography

- 5.3.1 Asia-Pacific

- 5.3.1.1 China

- 5.3.1.2 India

- 5.3.1.3 Japan

- 5.3.1.4 South Korea

- 5.3.1.5 ASEAN Countries

- 5.3.1.6 Rest of Asia-Pacific

- 5.3.2 North America

- 5.3.2.1 United States

- 5.3.2.2 Canada

- 5.3.2.3 Mexico

- 5.3.3 Europe

- 5.3.3.1 Germany

- 5.3.3.2 United Kingdom

- 5.3.3.3 France

- 5.3.3.4 Italy

- 5.3.3.5 Spain

- 5.3.3.6 Russia

- 5.3.3.7 Rest of Europe

- 5.3.4 South America

- 5.3.4.1 Brazil

- 5.3.4.2 Argentina

- 5.3.4.3 Rest of South America

- 5.3.5 Middle-East and Africa

- 5.3.5.1 Saudi Arabia

- 5.3.5.2 South Africa

- 5.3.5.3 Rest of Middle-East and Africa

- 5.3.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share (%)/Ranking Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share, Products and Services, and Recent Developments)

- 6.4.1 Aluminium Bahrain B.S.C. (Alba)

- 6.4.2 BP p.l.c

- 6.4.3 Chevron Corp

- 6.4.4 China Petroleum & Chemical Corporation (Sinopec)

- 6.4.5 CNOOC Limited

- 6.4.6 ELSID SA

- 6.4.7 Exxon Mobil Corp

- 6.4.8 Indian Oil Corporation

- 6.4.9 Maniayargroup

- 6.4.10 Marathon Petroleum

- 6.4.11 Numaligarh Refinery Limited

- 6.4.12 Oxbow Corporation

- 6.4.13 Petrocoque

- 6.4.14 Phillips 66 Company

- 6.4.15 Rain Carbon Inc.

- 6.4.16 Reliance Industries Ltd

- 6.4.17 Rio Tinto

- 6.4.18 Saudi Aramco

- 6.4.19 Saudi Calcined Petroleum Coke Company (SCPC)

- 6.4.20 Valero Energy Corp

- 6.4.21 Zhenjiang Coking And Gas Group Co. Ltd

7 Market Opportunities and Future Outlook

- 7.1 White-space and Unmet-Need Assessment