PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1910938

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1910938

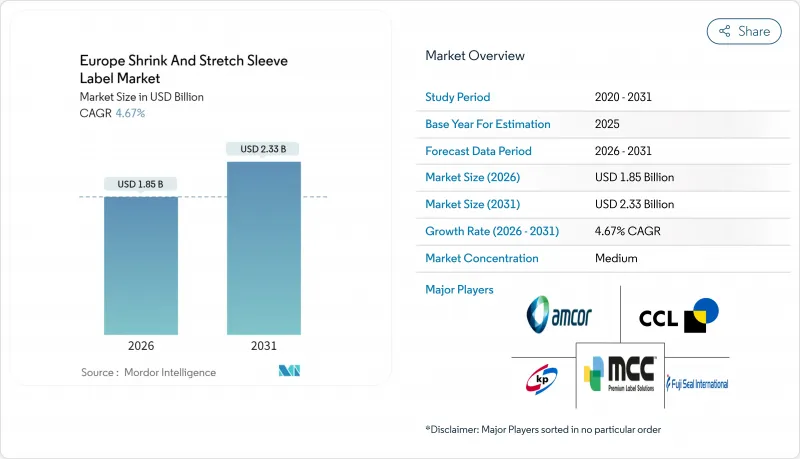

Europe Shrink And Stretch Sleeve Label - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2026 - 2031)

The Europe shrink and stretch sleeve label market was valued at USD 1.77 billion in 2025 and estimated to grow from USD 1.85 billion in 2026 to reach USD 2.33 billion by 2031, at a CAGR of 4.67% during the forecast period (2026-2031).

Sustained demand from premium consumer goods, tightening recyclability rules, and rapid investments in polyolefin converting lines underpin this steady trajectory. Beverage brands are re-engineering sleeves to survive deposit-return schemes without sacrificing visual impact, while personal care players scale 360-degree graphics to justify premium shelf pricing. Material substitution toward polyethylene accelerates as converters seek substrates that pass EU sorting trials. Competitive intensity rises as petrochemical consolidation inflates resin costs, forcing mid-tier converters to choose between capacity upgrades and exit. Inline digital printing unlocks cost-effective short runs that help brand owners localize campaigns and reduce inventory risk.

Europe Shrink And Stretch Sleeve Label Market Trends and Insights

Demand to Increase On-Shelf Appeal

Retail shelf space rationalization intensifies visual competition, prompting brand owners to adopt full-body sleeves that convert an ordinary container into a 360-degree billboard. Craft beverage lines exploit limited-edition graphics to boost unit margins, while mass-market soda brands rotate seasonal artwork without disrupting fill-line speeds. Western European consumers continue to reward premium aesthetics with repeat purchases, helping sleeves defend pricing versus pressure-sensitive labels. As retailers expand private-label ranges, national brands double down on differentiated decoration to avoid commoditization. The broader European packaging sector's value climb from EUR 153 billion in 2024 to EUR 186 billion by 2029 signals headroom for upscale formats.

Need for Tamper-Evident Protection

EU pharmacovigilance rules mandate overt security features, making shrink sleeves attractive because removal leaves visible damage. Nutraceutical producers embed micro-text and color-shift inks to authenticate packages at point of sale. Counterfeit concern has risen sharply since 2024, pushing supermarkets to favor tamper-proof formats even for premium juices. Government inspectors also prefer sleeves that signal breach instantly during cold-chain audits. Growing e-commerce adds another touch-point where packages can be compromised, further raising demand.

Stricter EU Plastics-Packaging Waste Directives

PPWR introduces design-for-recycling checklists that invalidate many legacy sleeve constructions overnight. Converters must finance line trials, laboratory tests, and third-party certifications before 2027 while absorbing EPR fees that escalate annually. Brand owners use the legislation to renegotiate pricing, squeezing suppliers during investment peaks. Western European enforcement agencies already issued EUR 7 million in packaging fines during 2024, underscoring near-term compliance risk.Cash-strapped SMEs defer upgrades, risking market exit.

Other drivers and restraints analyzed in the detailed report include:

- Shift Toward 360° Branding Surfaces

- Adoption of Recyclable Polyolefin Shrink Films

- Limited Recycling Streams for Multilayer Films

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Heat shrink sleeves represented 68.02% of the Europe shrink and stretch sleeve label market size in 2025 thanks to proven conformity around intricate bottle contours and integrated tamper-evidence on beverage lines. They remain the go-to choice for high-volume soda and water brands that run containers through steam tunnels at 50,000 bottles per hour. Yet regulatory and cost headwinds encourage brand owners to trial stretch sleeves, especially where container designs allow friction application without heat. The Europe shrink and stretch sleeve label market expects stretch formats to post a 5.61% CAGR through 2031 as removal ease becomes a compliance differentiator.

Converters hedging risk now operate dual-capability applicators, shifting between resin shrink ratios and stretch roll stocks to match customer specifications. The new equilibrium also benefits low-density polyethylene substrates that accommodate both technologies with minor oven adjustments. Early stretch adopters in personal care report 4% material savings versus shrink alternatives, helping offset resin inflation. Investment in perforation technology further future-proofs heat shrink lines by simplifying post-consumer detachment.

The Europe Shrink and Stretch Sleeve Label Market Report is Segmented by Type (Heat Shrink Sleeve, Stretch Sleeve, and More), Material (PVC, PET-G, PE, PP, and More), Application (Beverage, Food, Personal Care, and More), and Geography (Germany, France, United Kingdom, Italy, Russia, Poland, Netherlands, Spain, and Rest of Europe). The Market Forecasts are Provided in Terms of Value (USD).

List of Companies Covered in this Report:

- Amcor PLC

- CCL Industries Inc.

- Klockner Pentaplast GmbH and Co. KG

- Fuji Seal International Inc.

- Huhtamaki Oyj

- Smurfit WestRock PLC

- Mondi PLC

- Multi-Color Corporation

- Sleevezone Ltd.

- Folienprint Risse Etiketten GmbH

- Oerlemans Plastics B.V.

- Decomatic S.A.

- Polifilm Extrusion GmbH

- Maca S.r.l.

- Sleever International Company

- Derprosa Films S.L.U.

- DOW Chemical Company

- UPM Raflatac Oy

- Constantia Flexibles Group GmbH

- Avery Dennison Corporation

- Label-Aire Inc.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Demand to increase on-shelf appeal

- 4.2.2 Need for tamper-evident protection

- 4.2.3 Shift toward 360° branding surfaces

- 4.2.4 Adoption of recyclable polyolefin shrink films

- 4.2.5 Inline digital printing integration

- 4.2.6 Lithium-metal additive inks enabling ultra-thin sleeves

- 4.3 Market Restraints

- 4.3.1 Stricter EU plastics-packaging waste directives

- 4.3.2 Rising prices of virgin PET-G and PVC resins

- 4.3.3 Limited recycling streams for multi-layer films

- 4.3.4 Sleeve removal bottlenecks in EU deposit-return schemes

- 4.4 Industry Value Chain Analysis

- 4.5 Regulatory Landscape

- 4.6 Technological Outlook

- 4.7 Porter's Five Forces Analysis

- 4.7.1 Threat of New Entrants

- 4.7.2 Bargaining Power of Suppliers

- 4.7.3 Bargaining Power of Buyers/Consumers

- 4.7.4 Threat of Substitute Products

- 4.7.5 Intensity of Competitive Rivalry

- 4.8 Major Machine Suppliers

5 MARKET SIZE AND GROWTH FORECASTS (VALUE)

- 5.1 By Type

- 5.1.1 Heat Shrink Sleeve

- 5.1.2 Stretch Sleeve

- 5.1.3 Other Types

- 5.2 By Material

- 5.2.1 Polyvinyl Chloride (PVC)

- 5.2.2 Polyethylene Terephthalate Glycol-modified (PET-G)

- 5.2.3 Polyethylene (PE)

- 5.2.4 Polypropylene (PP)

- 5.2.5 Other Materials

- 5.3 By Application

- 5.3.1 Beverage

- 5.3.2 Food

- 5.3.3 Personal Care

- 5.3.4 Other Applications

- 5.4 By Country

- 5.4.1 Germany

- 5.4.2 France

- 5.4.3 United Kingdom

- 5.4.4 Italy

- 5.4.5 Russia

- 5.4.6 Poland

- 5.4.7 Netherlands

- 5.4.8 Spain

- 5.4.9 Rest of Europe

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 Amcor PLC

- 6.4.2 CCL Industries Inc.

- 6.4.3 Klockner Pentaplast GmbH and Co. KG

- 6.4.4 Fuji Seal International Inc.

- 6.4.5 Huhtamaki Oyj

- 6.4.6 Smurfit WestRock PLC

- 6.4.7 Mondi PLC

- 6.4.8 Multi-Color Corporation

- 6.4.9 Sleevezone Ltd.

- 6.4.10 Folienprint Risse Etiketten GmbH

- 6.4.11 Oerlemans Plastics B.V.

- 6.4.12 Decomatic S.A.

- 6.4.13 Polifilm Extrusion GmbH

- 6.4.14 Maca S.r.l.

- 6.4.15 Sleever International Company

- 6.4.16 Derprosa Films S.L.U.

- 6.4.17 DOW Chemical Company

- 6.4.18 UPM Raflatac Oy

- 6.4.19 Constantia Flexibles Group GmbH

- 6.4.20 Avery Dennison Corporation

- 6.4.21 Label-Aire Inc.

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-space and Unmet-Need Assessment