PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1911700

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1911700

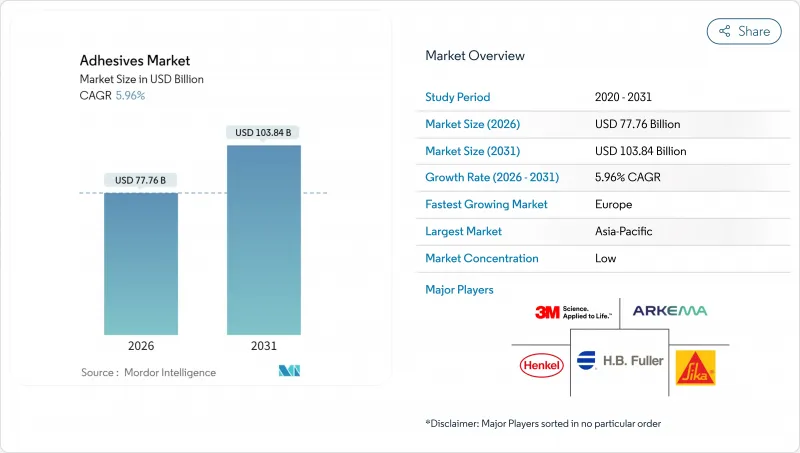

Adhesives - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2026 - 2031)

The Adhesives market is expected to grow from USD 73.39 billion in 2025 to USD 77.76 billion in 2026 and is forecast to reach USD 103.84 billion by 2031 at 5.96% CAGR over 2026-2031.

Demand accelerates as packaging automation scales with e-commerce, infrastructure programs prioritize structural bonding, and automakers increase adhesive volumes to support lightweight multi-material designs. Water-borne chemistries dominate because brands must meet VOC limits, yet hot-melt platforms gain share through solvent-free processing and rapid line speeds. Within resins, acrylics continue to rule high-performance applications, while VAE/EVA lines capture construction volumes thanks to flexibility and cost efficiency. Regional dynamics diverge, with Asia-Pacific supplying volume growth and Europe advancing premium, regulation-ready grades.

Global Adhesives Market Trends and Insights

E-commerce Boom Enlarging Demand for Secure, High-Speed Packaging Adhesives

Online retail warehouses rely on hot-melt and pressure-sensitive grades that cure in milliseconds yet sustain box integrity through conveyor impacts and multi-modal shipping. Fulfilment centers report double-digit order growth, driving 15-20% volume increases for packaging adhesives in key e-commerce corridors. India's online retail sector alone lifted packaging-adhesive offtake by 18% in 2024 as brand owners mandated tamper-evident bonds suitable for tropical climates. Sustainability goals add momentum for water-borne and bio-sourced options compatible with paper recycling streams. Packagers now specify easily removable grades that leave substrates clean, easing secondary fiber recovery.

Global Construction Upcycle Raising Consumption of Structural and Flooring Adhesives

Megaproject pipelines in Asia-Pacific accelerate uptake of high-strength, fast-set formulations for concrete, steel, and composite bonding where mechanical fasteners are slow or prone to failure. Large-format tiles and pre-fabricated panels need shear-resistant adhesives that shorten installation cycles and enhance structural integrity. Wacker Chemie expanded VAE capacity in Nanjing and Calvert City during 2024 to serve rising construction-adhesive demand in tile and insulation systems. Energy-retrofit incentives in Europe and North America sustain airflow-sealant and insulation-adhesive volumes, while updated building codes champion bonded joints for seismic resilience and thermal-bridge reduction.

Petro-Feedstock Price Volatility Squeezing Manufacturer Margins

Crude-linked monomers such as ethylene and propylene account for up to 60% of adhesive raw-material cost. Acrylic-acid prices swung 25-30% during 2024, forcing quarterly surcharges that erode margins, especially for smaller converters without hedging power. Currency shakiness multiplies the burden for firms that source globally but invoice locally. To blunt volatility, producers adopt dual-sourcing and inventory-risk strategies, yet these raise logistics complexity and working-capital needs.

Other drivers and restraints analyzed in the detailed report include:

- Lightweighting and EV Platforms Accelerating Automotive Adhesive Penetration

- Near-Shoring of Acrylic Monomer Supply in the United States

- Escalating VOC and Chemicals Regulation Curbing Solvent-Borne Sales

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Acrylic systems held a 22.60% share of the global adhesives market in 2025, supported by weather-resistant performance across construction facades, automotive trim, and pressure-sensitive labels. VAE/EVA lines are growing at a 6.28% CAGR through 2031, propelled by flexible flooring, tile-setting, and packaging-film lamination. Polyurethane grades stay entrenched in transportation and aerospace where high bond strength, chemical resistance, and elasticity are critical. Epoxies serve electronics and wind-blade joints that face extreme heat and fatigue, though their growth lags due to longer cure cycles. Hybrid chemistries now combine acrylic UV resistance with polyurethane toughness or VAE flexibility with epoxy rigidity, widening formulator toolkits.

Continuous resin innovation keeps the global adhesives market expanding as converters fine-tune performance for specific substrates and service environments. Acrylic players invest in self-crosslinking emulsions that boost water whitening resistance, while VAE suppliers ramp polar-monomer content to enhance adhesion to low-surface-energy films. Demand for bio-based feedstocks rises, yet cost and supply scalability limit rapid penetration. Strategic resin selection increasingly balances regulatory compliance, service temperature, and total applied cost, enabling manufacturers to differentiate within commoditized end uses.

The Adhesives Report is Segmented by Resin (Polyurethane, Epoxy, Acrylic, Cyanoacrylate, VAE/EVA, and More), Technology (Water-Borne, Solvent-Borne, Reactive, and More), End-User Industry (Building and Construction, Packaging, Automotive, Aerospace, Woodworking and Joinery, and More), and Geography (Asia-Pacific, North America, Europe, and More). The Market Forecasts are Provided in Terms of Value (USD)

Geography Analysis

Asia-Pacific holds 36.30% of the global adhesives market thanks to concentrated manufacturing clusters and public infrastructure spending across China, India, and Southeast Asia. China's urban rail and residential projects spur demand for structural acrylics, while India's tile-adhesive segment grows more than 15% annually on rapid urban housing. Regional suppliers, including new Henkel and tesa plants, enhance local availability and cut lead times. Overcapacity concerns persist, particularly in EVA and acrylic emulsions, where planned expansions risk surplus inventory if downstream uptake slows.

Europe is forecast to post the fastest 6.25% CAGR through 2031 as regulations push converters toward recyclable, low-emission systems. The EU Packaging and Packaging Waste Regulation, effective in 2026, will require adhesives that separate cleanly in mechanical recycling streams and eliminate PFAS content. Germany's EV transition drives demand for thermally conductive and flame-retardant adhesives, while France's building-retrofit subsidies stimulate insulation-bond volumes.

North America records steady momentum as tariff-induced monomer investments bolster supply security. Gulf Coast acrylic-acid capacity coming online from 2025 lessens reliance on imports and supports regional formulators with shorter transit times. Mexico's role as an automotive export hub lifts demand for structural and hem-flange bonding systems, whereas Canada's cold-weather construction codes favor freeze-resistant adhesives for panelized housing. The trajectory hinges on infrastructure-bill progress and automotive production cycles but remains positive amid reshoring and sustainability commitments.

- 3M

- Aica Kogyo Co..Ltd.

- Arkema

- AVERY DENNISON CORPORATION

- Dow

- H.B. Fuller Company

- Henkel AG & Co. KGaA

- Huntsman International LLC

- Illinois Tool Works Inc.

- Jowat SE

- MAPEI S.p.A.

- NANPAO RESINS CHEMICAL GROUP

- Pidilite Industries Ltd.

- Sika AG

- Soudal Holding N.V.

- Wacker Chemie AG

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 E-commerce boom enlarging demand for secure, high-speed packaging adhesives

- 4.2.2 Global construction upcycle raising consumption of structural and flooring adhesives

- 4.2.3 Lightweighting and EV platforms accelerating automotive adhesive penetration

- 4.2.4 AI-driven formulation optimisation slashing research and development timelines and custom-bonding costs

- 4.2.5 Near-shoring of acrylic monomer supply in US post-2025 tariffs reshapes regional capacity

- 4.3 Market Restraints

- 4.3.1 Petro-feedstock price volatility squeezing adhesive manufacturer margins

- 4.3.2 Escalating VOC and chemicals regulation curbing solvent-borne adhesive sales

- 4.3.3 Global shortage of senior adhesive formulators slowing commercialisation cycles

- 4.4 Value Chain Analysis

- 4.5 Porter's Five Forces

- 4.5.1 Bargaining Power of Suppliers

- 4.5.2 Bargaining Power of Buyers

- 4.5.3 Threat of New Entrants

- 4.5.4 Threat of Substitutes

- 4.5.5 Competitive Rivalry

5 Market Size and Growth Forecasts (Value)

- 5.1 By Resin

- 5.1.1 Polyurethane

- 5.1.2 Epoxy

- 5.1.3 Acrylic

- 5.1.4 Cyanoacrylate

- 5.1.5 VAE/EVA

- 5.1.6 Silicone

- 5.1.7 Other Resins

- 5.2 By Technology

- 5.2.1 Water-borne

- 5.2.2 Solvent-borne

- 5.2.3 Reactive

- 5.2.4 Hot Melt

- 5.2.5 UV Cured Adhesives

- 5.3 By End-user Industry

- 5.3.1 Building and Construction

- 5.3.2 Packaging

- 5.3.3 Automotive

- 5.3.4 Aerospace

- 5.3.5 Woodworking and Joinery

- 5.3.6 Footwear and Leather

- 5.3.7 Healthcare

- 5.3.8 Other End-user Industries

- 5.4 By Geography

- 5.4.1 Asia-Pacific

- 5.4.1.1 China

- 5.4.1.2 Japan

- 5.4.1.3 India

- 5.4.1.4 South Korea

- 5.4.1.5 Australia

- 5.4.1.6 Indonesia

- 5.4.1.7 Malaysia

- 5.4.1.8 Singapore

- 5.4.1.9 Thailand

- 5.4.1.10 Rest of Asia-Pacific

- 5.4.2 North America

- 5.4.2.1 United States

- 5.4.2.2 Canada

- 5.4.2.3 Mexico

- 5.4.3 Europe

- 5.4.3.1 Germany

- 5.4.3.2 United Kingdom

- 5.4.3.3 France

- 5.4.3.4 Italy

- 5.4.3.5 Spain

- 5.4.3.6 Russia

- 5.4.3.7 Rest of Europe

- 5.4.4 South America

- 5.4.4.1 Brazil

- 5.4.4.2 Argentina

- 5.4.4.3 Rest of South America

- 5.4.5 Middle-East and Africa

- 5.4.5.1 Saudi Arabia

- 5.4.5.2 South Africa

- 5.4.5.3 Rest of Middle-East and Africa

- 5.4.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share (%)/Ranking Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 3M

- 6.4.2 Aica Kogyo Co..Ltd.

- 6.4.3 Arkema

- 6.4.4 AVERY DENNISON CORPORATION

- 6.4.5 Dow

- 6.4.6 H.B. Fuller Company

- 6.4.7 Henkel AG & Co. KGaA

- 6.4.8 Huntsman International LLC

- 6.4.9 Illinois Tool Works Inc.

- 6.4.10 Jowat SE

- 6.4.11 MAPEI S.p.A.

- 6.4.12 NANPAO RESINS CHEMICAL GROUP

- 6.4.13 Pidilite Industries Ltd.

- 6.4.14 Sika AG

- 6.4.15 Soudal Holding N.V.

- 6.4.16 Wacker Chemie AG

7 Market Opportunities and Future Outlook

- 7.1 White-space and Unmet-Need Assessment