PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1911726

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1911726

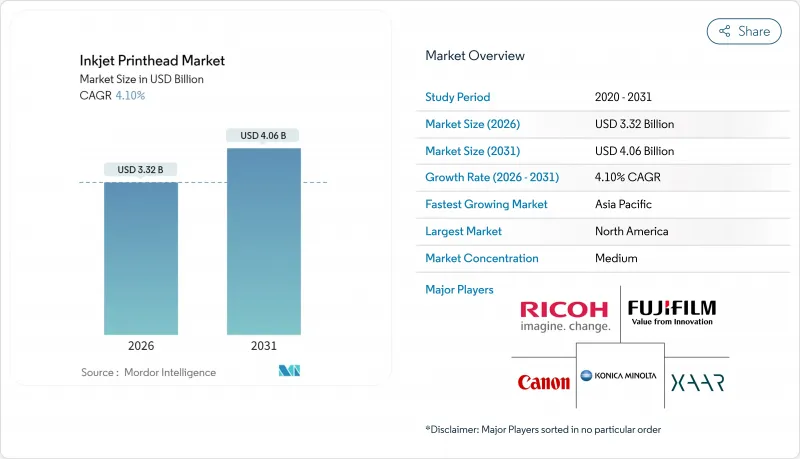

Inkjet Printhead - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2026 - 2031)

The inkjet printhead market is expected to grow from USD 3.19 billion in 2025 to USD 3.32 billion in 2026 and is forecast to reach USD 4.06 billion by 2031 at 4.1% CAGR over 2026-2031.

A migration from office printing toward high-precision industrial use underpins this trajectory as manufacturers exploit micro-electromechanical systems, thin-film piezo actuators, and single-pass architectures. Robust e-commerce activity, brand personalization strategies, and rising sustainability mandates are reinforcing demand for water-based pigmented inks, while additive manufacturing creates fresh, high-margin opportunities. Established vendors defend their positions through multi-year patent portfolios and platform sales models that expand the accessible customer base without diluting margins. Supply chain volatility in ceramics and semiconductors continues to pressure gross profits, yet predictive-maintenance analytics soften downtime risks and lift overall equipment effectiveness.

Global Inkjet Printhead Market Trends and Insights

Explosion of Single-Pass Digital Presses in Packaging and Textiles

Single-pass presses eliminate multi-pass cycles and cut production time by up to 70%, making short runs financially viable. EFI's Nozomi C18000 installs across European converters and delivers 400 linear ft/min at 1,200 dpi, validating throughput economics. Textile producers observe similar gains; Kornit's Atlas MAX handles seasonal micro-batches without sacrificing color accuracy. Demand for agile turnaround fuels sustained printhead orders, especially those rated for diverse viscosities and high-speed operation. As personalization expands within packaging, single-pass systems transform once-static production lines into flexible, data-driven assets. Because each unit uses multiple rows of piezo heads, the technology generates a steady pull-through for component suppliers.

MEMS and Thin-Film Piezo Allowing < 2 pL Drops at 300 m/min

MEMS nozzle arrays paired with thin-film actuators achieve sub-2 picoliter droplets at line speeds of 300 m/min, unlocking precision tasks such as pharmaceutical coatings and fine-line circuitry. Xaar's 2024 patent series details independent drive electronics for each nozzle that modulate volume on the fly. Kyocera's KJ4 platform commercialized the concept with 600 nozzles/inch and variable drops from 1.5 to 42 pL, enabling both graphics and functional deposition. The advance reduces ink waste and lowers operating costs because smaller drops translate into less pigment usage per square meter. Over the long term, these heads underpin bioprinting and smart-packaging initiatives where accuracy outranks raw speed.

Cap-ex Premium versus Laser and Analog Heads

Advanced inkjet lines cost 40-60% more than laser coders or flexo presses with similar throughput. Small manufacturers in price-sensitive regions delay upgrades despite lower setup and plate costs over the long haul. Financing programs offered by OEMs soften initial barriers, yet ROI calculations still favor legacy kit for mono-color marking or ultra-high-volume SKUs. Currency volatility in emerging economies reinforces the hesitation, slightly tempering the inkjet printhead market growth pace.

Other drivers and restraints analyzed in the detailed report include:

- OEM Shift to Open-Platform Printhead Sales

- Sustainability Push for Water-Based Pigmented Inks

- Clogging Risk with Nanoparticle and White Inks

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Drop-on-Demand accounted for 67.98% of the inkjet printhead market share in 2025, far outpacing continuous-flow systems. Piezo-based variants supply industrial sites that require sub-2 pL accuracy without thermal stress, while thermal cartridges hold ground in cost-sensitive office devices. The segment is forecast to post a 5.17% CAGR, reflecting continuous material science refinements rather than unit-growth spikes. Continuous technology retains coding niches where uninterrupted streams enable top speeds, but precision shortfalls curb its broader penetration.

Thin-film actuators cut power draw and raise native resolution to 1,200 dpi, giving Drop-on-Demand an advantage in high-density graphics and functional printing. Ricoh's MH5421F ships with multi-drop waveforms that lay down 4-42 pL volumes on demand, serving both signage and PCB substrates. As single-pass lines spread across corrugated and textile plants, each machine integrates hundreds of nozzles, embedding a substantial replacement-spares annuity into the inkjet printhead market size.

Aqueous inks commanded 31.76% revenue in 2025, buoyed by regulatory incentives and stronger pigment-encapsulation chemistries. UV-curables trail but are set to log a 5.72% CAGR to 2031, lifted by LED curing that bonds instantly to plastics and metals without high-heat exposure. Solvent fluids persist in outdoor banners where weathering resistance overrides environmental trade-offs, and latex blends serve high-stretch textiles that need elasticity.

Bio-based formulations occupy a rising niche as brand owners target circular-economy metrics. INX's plant-derived portfolio shows that sustainable inputs no longer compromise gamut or durability. UV heads, meanwhile, penetrate folding carton lines because instant cure accelerates lamination steps, trimming total turnaround.

The Inkjet Printhead Market Report is Segmented by Technology Type (Drop-On-Demand, and Continuous), Ink Type (Aqueous, Solvent-Based, UV-Curable, and More), Application (Packaging and Labeling, Textile Printing, and More), End-User (Office and Consumer-Based, Industrial Printing, Graphic Printing, and More), and Geography. The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

North America maintained 39.70% of 2025 revenue on the strength of entrenched R&D ecosystems and swift uptake of predictive-maintenance platforms. Federal environmental rules that restrict solvent discharge spur investment in water-based upgrades, and a mature e-commerce backbone secures demand for serialized, scannable packaging.

Asia-Pacific is expected to post a 6.43% CAGR, propelled by Chinese smart-factory programs and Japanese actuator know-how. Epson's new Chinese assembly hubs shorten lead times and hedge currency swings, whereas Mimaki's TS200 aims at Southeast Asian polyester mills with sublimation heads attuned to high-stretch fabrics. Regional cost advantages attract OEM outsourcing, intensifying local component clusters for ceramics and MEMS chips integral to inkjet jets.

Europe remains technology-rich but growth-mature as replacement buying overtakes greenfield installations. REACH regulations accelerate switchover to low-VOC fluids, and Koenig and Bauer Durst deploys carton presses that justify high cap-ex via premium short-run jobs. Government incentives for circular packaging underpin steady head retrofits across food and pharma converters.

- Ricoh Company, Ltd.

- FUJIFILM Holdings Corporation

- Canon Inc.

- Konica Minolta, Inc.

- Xaar plc

- Memjet Holdings Ltd.

- Funai Electric Co., Ltd.

- Kyocera Corporation

- Toshiba Corporation

- HP Development Company, L.P.

- Seiko Epson Corporation

- Xerox Holdings Corporation

- Domino Printing Sciences plc

- Brother Industries, Ltd.

- Hitachi Industrial Equipment Systems Co., Ltd.

- Videojet Technologies, Inc.

- Lexmark International, Inc.

- Panasonic Holdings Corporation

- Durst Group AG

- Kodak Alaris, Inc.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Explosion of single-pass digital presses in packaging and textiles

- 4.2.2 MEMS and thin-film piezo allowing <2 pL drops at 300 m/min

- 4.2.3 OEM shift to open-platform printhead sales (Epson, Xerox)

- 4.2.4 Sustainability push for water-based pigmented inks

- 4.2.5 AI-driven predictive maintenance lowering downtime

- 4.2.6 Emerging EHD printheads for high-viscosity functional fluids

- 4.3 Market Restraints

- 4.3.1 Cap-ex premium vs. laser and analog heads

- 4.3.2 Clogging risk with nanoparticle and white inks

- 4.3.3 Patent thickets limiting new entrant scalability

- 4.3.4 Volatile ceramics and semiconductor supply chains

- 4.4 Industry Value Chain Analysis

- 4.5 Technological Outlook

- 4.6 The Impact of Macroeconomic Factors on the Market

- 4.7 Porter's Five Forces Analysis

- 4.7.1 Bargaining Power of Suppliers

- 4.7.2 Bargaining Power of Buyers

- 4.7.3 Threat of New Entrants

- 4.7.4 Threat of Substitutes

- 4.7.5 Competitive Rivalry

- 4.8 Regulatory Landscape

5 MARKET SIZE AND GROWTH FORECASTS (VALUE)

- 5.1 By Technology Type

- 5.1.1 Drop-on-Demand

- 5.1.1.1 Thermal

- 5.1.1.2 Piezo-based

- 5.1.2 Continuous

- 5.1.1 Drop-on-Demand

- 5.2 By Ink Type

- 5.2.1 Aqueous

- 5.2.2 Solvent-based

- 5.2.3 UV-curable

- 5.2.4 Latex and Sublimation

- 5.2.5 Other Ink Types

- 5.3 By Application

- 5.3.1 Packaging and Labeling

- 5.3.2 Textile Printing

- 5.3.3 Electronics and Functional Materials

- 5.3.4 3D / Additive Manufacturing

- 5.3.5 Coding and Marking

- 5.3.6 Other Applications

- 5.4 By End-user

- 5.4.1 Office and Consumer-based

- 5.4.2 Industrial Printing

- 5.4.3 Graphic Printing

- 5.4.4 Other End-users

- 5.5 By Geographic

- 5.5.1 North America

- 5.5.1.1 United States

- 5.5.1.2 Canada

- 5.5.1.3 Mexico

- 5.5.2 South America

- 5.5.2.1 Brazil

- 5.5.2.2 Argentina

- 5.5.2.3 Rest of South America

- 5.5.3 Europe

- 5.5.3.1 Germany

- 5.5.3.2 United Kingdom

- 5.5.3.3 France

- 5.5.3.4 Italy

- 5.5.3.5 Spain

- 5.5.3.6 Rest of Europe

- 5.5.4 Asia-Pacific

- 5.5.4.1 China

- 5.5.4.2 Japan

- 5.5.4.3 India

- 5.5.4.4 South Korea

- 5.5.4.5 Australia

- 5.5.4.6 Rest of Asia-Pacific

- 5.5.5 Middle East and Africa

- 5.5.5.1 Middle East

- 5.5.5.1.1 Saudi Arabia

- 5.5.5.1.2 United Arab Emirates

- 5.5.5.1.3 Turkey

- 5.5.5.1.4 Rest of Middle East

- 5.5.5.2 Africa

- 5.5.5.2.1 South Africa

- 5.5.5.2.2 Nigeria

- 5.5.5.2.3 Rest of Africa

- 5.5.5.1 Middle East

- 5.5.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share for key companies, Products and Services, and Recent Developments)

- 6.4.1 Ricoh Company, Ltd.

- 6.4.2 FUJIFILM Holdings Corporation

- 6.4.3 Canon Inc.

- 6.4.4 Konica Minolta, Inc.

- 6.4.5 Xaar plc

- 6.4.6 Memjet Holdings Ltd.

- 6.4.7 Funai Electric Co., Ltd.

- 6.4.8 Kyocera Corporation

- 6.4.9 Toshiba Corporation

- 6.4.10 HP Development Company, L.P.

- 6.4.11 Seiko Epson Corporation

- 6.4.12 Xerox Holdings Corporation

- 6.4.13 Domino Printing Sciences plc

- 6.4.14 Brother Industries, Ltd.

- 6.4.15 Hitachi Industrial Equipment Systems Co., Ltd.

- 6.4.16 Videojet Technologies, Inc.

- 6.4.17 Lexmark International, Inc.

- 6.4.18 Panasonic Holdings Corporation

- 6.4.19 Durst Group AG

- 6.4.20 Kodak Alaris, Inc.

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-Space and Unmet-Need Assessment