PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1939584

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1939584

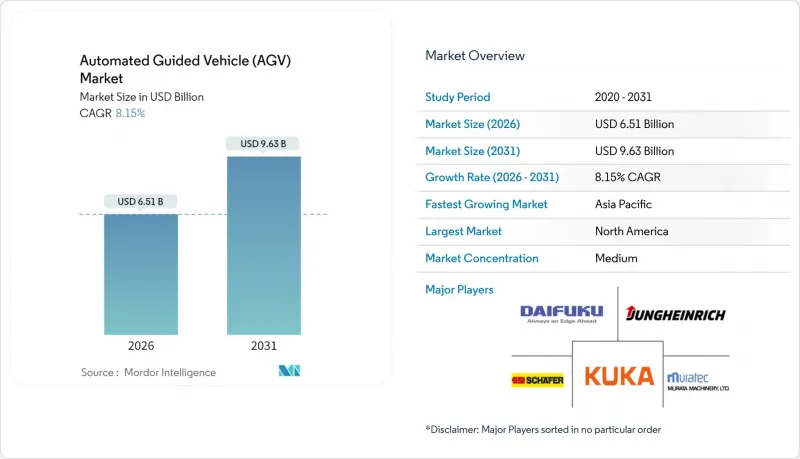

Automated Guided Vehicle (AGV) - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2026 - 2031)

The Automated Guided Vehicle market is expected to grow from USD 6.02 billion in 2025 to USD 6.51 billion in 2026 and is forecast to reach USD 9.63 billion by 2031 at 8.15% CAGR over 2026-2031.

Intensifying e-commerce order spikes, persistent labor shortages, and the need for round-the-clock, error-free material handling are underpinning this trajectory. Operators are turning to autonomous mobile fleets because peak-season order volumes can climb 300-400%, a level traditional manual processes cannot sustain. Private 5G networks now provide the deterministic connectivity AGVs require, delivering 20% productivity gains and 15% lower capex than Wi-Fi in early rollouts. AI-enabled navigation, most notably Visual SLAM, cuts commissioning time by 20% and allows layout re-configuration without physical guides. Heightened cybersecurity focus and looming rare-earth supply constraints temper enthusiasm, yet neither risk has slowed procurement to date.

Global Automated Guided Vehicle (AGV) Market Trends and Insights

Rapid Growth of E-commerce Fulfillment Automation

Omnichannel retail has pushed the automated guided vehicle market beyond efficiency gains and into business-continuity territory. Picking functions absorb roughly 55% of warehousing costs, prompting Kroger, Ocado and other large retailers to quadruple their fleets of goods-to-person robots to keep same-day-delivery promises. Real-time links between AGVs and warehouse-management software are trimming material-handling expenses by 70%. Urban micro-fulfillment sites, often below 1,000 m2, have become viable thanks to slimmer AGV form factors that maneuver in tight corridors. Modular procurement models allow smaller merchants to add vehicles as order volumes escalate, insulating them from large upfront bets. Collectively, these changes ensure the automated guided vehicle market continues scaling on the back of e-commerce growth.

Escalating Labor Costs and Workforce Scarcity

Warehousing attrition routinely exceeds 75%, and a global shortfall of 85 million workers is expected by 2030. In Japan, autonomous forklifts priced at 15 million yen still outcompete manual units because the labor pipeline is crumbling. Documented installations show payback in as little as eight months, strengthening the internal-rate-of-return case for AGVs. Round-the-clock operation without fatigue adds further value, while hybrid workforces pairing people with robots improve both throughput and job satisfaction. Labor scarcity therefore shifts AGV adoption from discretionary to mandatory in many distribution centers, powering growth across the automated guided vehicle market.

High Upfront Capital Expenditure for SMEs

Initial deployments range from USD 50,000 to USD 500,000 and can strain thin margins, especially where borrowing costs run high. Documented labor-intensive use cases, however, hit breakeven in 8-18 months when IoT inventory control accompanies the AGV rollout. Robots-as-a-Service models slash capex and embed ongoing technical support, with vendors such as Agility Robotics spearheading full-service contracts. R&D tax credits worth up to 10% and accelerated depreciation schedules under clean-industry guidelines further lighten cash burdens in North America and the EU. Despite near-term friction, financing innovations help SMEs enter the automated guided vehicle market sooner than in earlier cycles.

Other drivers and restraints analyzed in the detailed report include:

- Advancements in AI-enabled Navigation and Sensor Suites

- Surge in "Dark Warehouse" Adoption Among SMEs

- Shortage of Multi-disciplinary Maintenance Technicians

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Unit-Load platforms captured 31.48% of 2025 sales, anchoring the automated guided vehicle market with their ability to move pallets, containers and totes across multipurpose facilities. Automated Forklift models, though smaller at present, are projected for an 8.54% CAGR, reflecting demand for vertical-reach capability and compatibility with existing racking systems. Tow-tractor variants thrive in automotive plants where heavy framed components require sequential transfer, whereas assembly-line vehicles gain ground in electronics clean rooms that favor particle-free motion.

Demand is tilting toward forklift-style vehicles because multilevel warehouses proliferate in land-constrained cities and because dual-mode manual/autonomous operation eases change-management hurdles. Pallet-truck AGVs remain the first automation step for retailers handling inbound freight, while cart and small-load designs suit high-frequency e-commerce picks. Niche opportunities endure for explosion-proof and pharmaceutical-grade units. Collectively, these dynamics underpin sustained growth of the automated guided vehicle market across all product lines.

Automotive manufacturers owned 34.63% of 2025 turnover, using AGVs to feed just-in-time assembly and reduce work-in-process buffers. Yet retail and e-commerce distribution centers should outpace every other vertical at an 8.18% CAGR as same-day delivery becomes non-negotiable for consumers. Food-and-beverage operators extend AGV use into refrigerated zones to sidestep labor shortages in cold environments, while electronics producers exploit millimeter-level positioning for fragile sub-assemblies, reinforcing broader adoption in the automated guided vehicles market.

Pharmaceutical logistics increasingly turns to AGVs to comply with Good Distribution Practices, and third-party logistics firms report 42% labor-hour savings after installing robot fleets. Aerospace adopters demand tight tolerance handling for fuselage sections, spawning ultra-heavy-duty designs. These cross-industry shifts indicate a broadening customer base that strengthens the automated guided vehicle market without over-reliance on any single vertical.

The Automated Guided Vehicle (AGV) Market Report is Segmented by Product Type (Automated Forklift, Tow/Tractor/Tug, and More), End-User Industry (Automotive, Food and Beverage, and More), Payload Capacity (Less Than 500 Kg, 500-1, 000 Kg, 1, 000-2, 000 Kg, and More), Application (Material Handling and Transportation, Order Picking and Sortation, and More), and Geography. The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

North America retained 37.07% revenue share in 2025 in the AVG market due to hourly warehouse wages exceeding USD 25 and deeply entrenched e-commerce networks that demand high fulfillment velocity. Anchor customers such as Amazon and Walmart validate large-scale robotic deployments, which in turn create downstream supplier ecosystems. U.S. fiscal incentive, R&D credits and bonus depreciation schedules, ensure continued capital inflows even as interest rates rise, while Canada favors AGVs for cold-storage and resource-sector logistics.

Asia Pacific will log the fastest 8.36% CAGR through 2031, led by China's "dark factory" push and Japan's acute demographic-driven labor crunch. The region boasts the bulk of the world's 955 private 5G networks, a connectivity edge supporting latency-sensitive AGV controls. India's production-linked incentive schemes and ASEAN supply-chain diversification add new greenfield sites primed for automation.

Europe presents a steady, sustainability-oriented profile. The European Commission's Clean Industrial Transition guidelines extend accelerated depreciation to robotics, accelerating replacement of energy-intensive manual processes. Germany's automotive and machinery sectors adopt holistic Industry 4.0 architectures with AGVs at the core, while the United Kingdom prioritizes logistics hubs ringing major metropolitan areas. The Middle East, Africa and South America remain nascent but attractive for applications in mining, ports and petrochemicals where safety benefits justify investment, expanding the global automated guided vehicle market footprint.

- ABB Ltd.

- AutoStore AS

- BALYO SA

- Berkshire Grey, Inc.

- Clearpath Robotics Inc.

- Daifuku Co., Ltd.

- Dematic Corp. (KION Group)

- Elettric80 S.p.A.

- FANUC Corporation

- Fetch Robotics, Inc.

- John Bean Technologies Corporation

- Jungheinrich AG

- KUKA AG

- Locus Robotics Corp.

- Mobile Industrial Robots A/S

- Murata Machinery, Ltd.

- Oceaneering International, Inc.

- Omron Adept Technologies, Inc.

- Scott Technology Limited

- Seegrid Corporation

- SSI SCHAFER Systems International DWC LLC

- Swisslog Holding AG

- System Logistics S.p.A.

- Toyota Material Handling Co., Ltd.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET LANDSCAPE

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Rapid growth of e-commerce fulfillment automation

- 4.2.2 Escalating labor costs and workforce scarcity

- 4.2.3 Advancements in AI-enabled navigation and sensor suites

- 4.2.4 Surge in "dark warehouse" adoption among SMEs

- 4.2.5 Integration with private 5G networks for deterministic control

- 4.2.6 ESG-driven automation incentives in developed markets

- 4.3 Market Restraints

- 4.3.1 High upfront capital expenditure for SMEs

- 4.3.2 Shortage of multi-disciplinary maintenance technicians

- 4.3.3 Cyber-security liabilities in fleet management software

- 4.3.4 Scarcity of rare-earth materials for high-torque AGV motors

- 4.4 Regulatory Landscape

- 4.5 Technological Outlook

- 4.6 Porter's Five Forces Analysis

- 4.6.1 Bargaining Power of Suppliers

- 4.6.2 Bargaining Power of Buyers

- 4.6.3 Threat of New Entrants

- 4.6.4 Threat of Substitutes

- 4.6.5 Intensity of Competitive Rivalry

- 4.7 Impact of Macroeconomic and Post-Pandemic Factors

5 MARKET SIZE AND GROWTH FORECASTS (VALUE)

- 5.1 By Product Type

- 5.1.1 Automated Forklift AGVs

- 5.1.2 Tow / Tractor / Tug AGVs

- 5.1.3 Unit-Load AGVs

- 5.1.4 Assembly-Line AGVs

- 5.1.5 Pallet Truck AGVs

- 5.1.6 Cart and Small Load AGVs

- 5.1.7 Special-Purpose AGVs

- 5.1.8 Other Product Types

- 5.2 By End-User Industry

- 5.2.1 Automotive

- 5.2.2 Food and Beverage

- 5.2.3 Retail and E-Commerce

- 5.2.4 Electronics and Electrical

- 5.2.5 Pharmaceutical and Healthcare

- 5.2.6 Logistics and 3PL

- 5.2.7 Aerospace and Defense

- 5.2.8 General Manufacturing

- 5.2.9 Other End-User Industries

- 5.3 By Payload Capacity

- 5.3.1 Less than 500 kg

- 5.3.2 500 - 1,000 kg

- 5.3.3 1,000 - 2,000 kg

- 5.3.4 above 2,000 kg

- 5.4 By Application

- 5.4.1 Material Handling and Transportation

- 5.4.2 Order Picking and Sortation

- 5.4.3 Trailer Loading / Unloading

- 5.4.4 Packaging and Palletizing

- 5.4.5 Assembly Operations

- 5.4.6 Cold-Chain and Refrigerated Storage

- 5.4.7 Hazardous Materials Handling

- 5.5 By Geography

- 5.5.1 North America

- 5.5.1.1 United States

- 5.5.1.2 Canada

- 5.5.2 South America

- 5.5.2.1 Brazil

- 5.5.2.2 Argentina

- 5.5.2.3 Rest of South America

- 5.5.3 Europe

- 5.5.3.1 Germany

- 5.5.3.2 United Kingdom

- 5.5.3.3 France

- 5.5.3.4 Italy

- 5.5.3.5 Spain

- 5.5.3.6 Russia

- 5.5.3.7 Rest of Europe

- 5.5.4 Asia Pacific

- 5.5.4.1 China

- 5.5.4.2 Japan

- 5.5.4.3 South Korea

- 5.5.4.4 India

- 5.5.4.5 ASEAN

- 5.5.4.6 Rest of Asia Pacific

- 5.5.5 Middle East and Africa

- 5.5.5.1 Middle East

- 5.5.5.1.1 United Arab Emirates

- 5.5.5.1.2 Saudi Arabia

- 5.5.5.1.3 Turkey

- 5.5.5.1.4 Rest of Middle East

- 5.5.5.2 Africa

- 5.5.5.2.1 South Africa

- 5.5.5.2.2 Egypt

- 5.5.5.2.3 Rest of Africa

- 5.5.5.1 Middle East

- 5.5.1 North America

6 COMPETITIVE LANDSCAPE

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share Analysis

- 6.4 Company Profiles (includes Global-level Overview, Market-level Overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share, Products and Services, Recent Developments)

- 6.4.1 ABB Ltd.

- 6.4.2 AutoStore AS

- 6.4.3 BALYO SA

- 6.4.4 Berkshire Grey, Inc.

- 6.4.5 Clearpath Robotics Inc.

- 6.4.6 Daifuku Co., Ltd.

- 6.4.7 Dematic Corp. (KION Group)

- 6.4.8 Elettric80 S.p.A.

- 6.4.9 FANUC Corporation

- 6.4.10 Fetch Robotics, Inc.

- 6.4.11 John Bean Technologies Corporation

- 6.4.12 Jungheinrich AG

- 6.4.13 KUKA AG

- 6.4.14 Locus Robotics Corp.

- 6.4.15 Mobile Industrial Robots A/S

- 6.4.16 Murata Machinery, Ltd.

- 6.4.17 Oceaneering International, Inc.

- 6.4.18 Omron Adept Technologies, Inc.

- 6.4.19 Scott Technology Limited

- 6.4.20 Seegrid Corporation

- 6.4.21 SSI SCHAFER Systems International DWC LLC

- 6.4.22 Swisslog Holding AG

- 6.4.23 System Logistics S.p.A.

- 6.4.24 Toyota Material Handling Co., Ltd.

7 MARKET OPPORTUNITIES AND FUTURE OUTLOOK

- 7.1 White-Space and Unmet-Need Assessment