PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1687115

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1687115

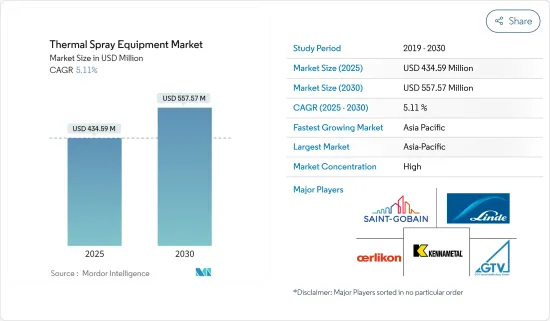

Thermal Spray Equipment - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030)

The Thermal Spray Equipment Market size is estimated at USD 434.59 million in 2025, and is expected to reach USD 557.57 million by 2030, at a CAGR of 5.11% during the forecast period (2025-2030).

The market was negatively impacted in 2020 because of the COVID-19 pandemic. The nationwide lockdowns and stringent social distancing mandates caused supply chain disruptions across various markets. However, in 2021, the demand from various sectors recovered and is expected to grow at a significant rate in the coming years.

Key Highlights

- Major factors driving the market study are the rising popularity of thermal spray ceramic coatings, the increasing use of thermal spray coatings in the aerospace industry, and the evolution in the power generation sector.

- On the flip side, issues regarding process reliability and consistency hinder the growth of the market studied.

- Current progress in solution precursor plasma spraying of cermets, advancements in the cold spray process, the emergence of HVOF coatings and systems, and growth prospects for twin wire arc thermal spraying systems are expected to offer various opportunities for the growth of the market studied.

- The Asia-Pacific region is expected to dominate the global market during the forecast period.

Thermal Spray Equipment Market Trends

Rising Application in the Aerospace Industry

- Thermal spray equipment is employed for several purposes in jet engine components, such as crankshafts, piston rings, cylinders, valves, etc. In addition, it is also applied in the coating of landing gear to withstand the forces during landing and take-off.

- Thermal spray coatings systems are used for coating purposes in rocket combustion chambers, compressor air seals, and high-pressure nozzles. Coatings of chromium cobalt, aluminum oxide, and chromium carbide are employed in turbine air seals, fuel nozzles, and turbine vanes, respectively.

- Boeing led the aerospace industry to adapt and implement thermal spray equipment as an alternative for hard chromium plating on numerous structural components. According to the Boeing Commercial Outlook 2022-2041, the global forecast for commercial aviation services (which include flight operations, maintenance and engineering, ground, station, and cargo operations, and others) is expected to be USD 3,615 billion by 2041.

- Furthermore, according to the International Air Transport Association (IATA), the global revenue for commercial airlines was valued at USD 373 billion in 2020 and was estimated at USD 472 billion in 2021, registering a growth rate of 26.7% Y-o-Y. Furthermore, the revenue was expected to reach USD 658 billion by 2022.

- Aircraft manufacturers are looking for ways to accelerate production to fill order backlogs. For instance, according to the Boeing Commercial Outlook 2022-2041, the total global deliveries of new airplanes are estimated to be 41,170 by 2041. The global airplane fleet amounted to around 25,900 units as of the year 2019 and the fleet number is likely to reach 47,080 units by 2041.

- Overall, there is a promising growth for the demand for thermal spray equipment in the aerospace industry over the forecast period.

China to Dominate the Asia-Pacific Region

- The thermal spray equipment market in China is experiencing healthy growth, mirroring the manufacturing section of the aerospace and automotive industry of the country.

- China is one of the largest steel producers, and steel mills use thermal spray coatings for protection. The steel industry mainly uses coatings of processing rolls by HVOF, spray fusing, plasma spraying, and plasma-transferred arc overlaying welding.

- The Chinese aerospace policy represents one of the most comprehensive attempts to enter the top levels of aerospace development and production. China has the second-largest domestic aviation market in the world. It also has the world's fastest-growing domestic aviation industry, with passenger traffic increasing at 6.6% per year.

- In China, according to the Boeing Commercial Outlook 2022-2041, around 8,485 new deliveries will be made by 2041 with a market service value of USD 545 billion.

- According to the International Organization of Motor Vehicle Manufacturers (OICA), China has the largest automotive production base in the world, with a total vehicle production of 26.08 million units in 2021, registering an increase of 3% compared to 25.23 million units produced in last year.

- A growth of 106% in battery-plugged electric vehicles was witnessed in November 2021 compared to the same period in 2020. The country's sales of electric vehicles reached around 413,094 units in November 2021. In addition, the market share also increased to 19%, including 15% of all-electric and 4% of plug-in hybrid cars.

Thermal Spray Equipment Industry Overview

The global thermal spray equipment market is partially consolidated in nature. The major players in the market studied include (not in any particular order) Oerlikon, Linde, GTV Verschleibschutz GmbH, Kennametal, and Saint-Gobain, amongst others.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET DYNAMICS

- 4.1 Drivers

- 4.1.1 Rising Application in Aerospace Industry

- 4.1.2 Rising Popularity of Thermal Spray Ceramic Coatings

- 4.1.3 Evolution in Power Generation Sector

- 4.2 Restraints

- 4.2.1 Issues Regarding Process Reliability and Consistency

- 4.3 Industry Value Chain Analysis

- 4.4 Porter's Five Forces Analysis

- 4.4.1 Bargaining Power of Suppliers

- 4.4.2 Bargaining Power of Consumers

- 4.4.3 Threat of New Entrants

- 4.4.4 Threat of Substitute Products and Services

- 4.4.5 Degree of Competition

- 4.5 Technological Snapshot

5 MARKET SEGMENTATION (Market Size in Value)

- 5.1 Product Type

- 5.1.1 Thermal Spray Coating Systems

- 5.1.2 Dust Collection Equipment

- 5.1.3 Spray Guns and Nozzles

- 5.1.4 Feeder Equipment

- 5.1.5 Spare Parts

- 5.1.6 Noise-reducing Enclosures

- 5.1.7 Other Product Types

- 5.2 Process

- 5.2.1 Combustion

- 5.2.2 Electric Energy

- 5.3 End-user Industry

- 5.3.1 Aerospace

- 5.3.2 Industrial Gas Turbines

- 5.3.3 Automotive

- 5.3.4 Electronics

- 5.3.5 Oil and Gas

- 5.3.6 Medical Devices

- 5.3.7 Energy and Power

- 5.3.8 Other End-user Industries

- 5.4 Geography

- 5.4.1 Asia-Pacific

- 5.4.1.1 China

- 5.4.1.2 India

- 5.4.1.3 Japan

- 5.4.1.4 South Korea

- 5.4.1.5 ASEAN Countries

- 5.4.1.6 Rest of Asia-Pacific

- 5.4.2 North America

- 5.4.2.1 United States

- 5.4.2.2 Canada

- 5.4.2.3 Mexico

- 5.4.3 Europe

- 5.4.3.1 Germany

- 5.4.3.2 United Kingdom

- 5.4.3.3 France

- 5.4.3.4 Italy

- 5.4.3.5 Rest of Europe

- 5.4.4 South America

- 5.4.4.1 Brazil

- 5.4.4.2 Argentina

- 5.4.4.3 Rest of South America

- 5.4.5 Middle-East and Africa

- 5.4.5.1 Saudi Arabia

- 5.4.5.2 South Africa

- 5.4.5.3 Rest of Middle-East and Africa

- 5.4.1 Asia-Pacific

6 COMPETITIVE LANDSCAPE

- 6.1 Mergers, Acquisitions, Joint Ventures, Collaborations, and Agreements

- 6.2 Market Ranking Analysis

- 6.3 Strategies Adopted by Leading Players

- 6.4 Company Profiles

- 6.4.1 Air Products and Chemicals Inc.

- 6.4.2 Lincotek Equipment

- 6.4.3 Arzell Inc.

- 6.4.4 ASB Industries Inc.

- 6.4.5 Bay State Surface Technologies Inc. (Aimtek)

- 6.4.6 Camfil Air Pollution Control

- 6.4.7 Castolin Eutectic

- 6.4.8 Donaldson Company Inc.

- 6.4.9 Flame Spray Technologies BV

- 6.4.10 Thermion

- 6.4.11 GTV Verschleibschutz GmbH

- 6.4.12 HAI Inc.

- 6.4.13 Imperial Systems Inc.

- 6.4.14 Kennametal Inc.

- 6.4.15 Linde

- 6.4.16 CenterLine Holdings Inc. (Supersonic Spray Technologies)

- 6.4.17 Metallisation Ltd

- 6.4.18 Metallizing Equipment Co. Pvt. Ltd

- 6.4.19 OC Oerlikon Management AG

- 6.4.20 Plasma Powders & Systems Inc.

- 6.4.21 Powder Feed Dynamics Inc.

- 6.4.22 Progressive Surface

- 6.4.23 Saint-Gobain

7 MARKET OPPORTUNITIES AND FUTURE TRENDS

- 7.1 Current Progress in Solution Precursor Plasma Spraying of Cermets

- 7.2 Advancements in Cold Spray Process

- 7.3 Emergence of HVOF Coatings and Systems

- 7.4 Growth Prospects for Twin Wire Arch Thermal Spraying Systems