PUBLISHER: Roots Analysis | PRODUCT CODE: 1919791

PUBLISHER: Roots Analysis | PRODUCT CODE: 1919791

AI in Pharma Manufacturing Market, till 2040: Distribution by Type of Offering, Mode of Deployment, Type of AI Solution, Type of Technology, Application Area, Utility in Drug Manufacturing, Geographical Regions and Key Players

AI in Pharma Manufacturing Market Outlook

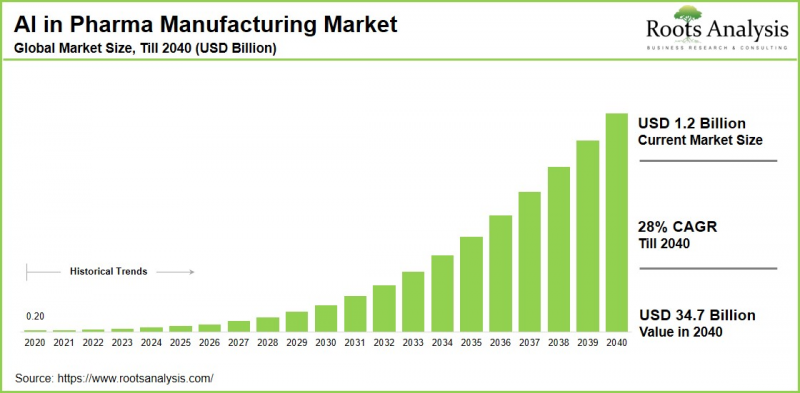

As per Roots Analysis, the global AI in pharma manufacturing market size is estimated to grow from USD 1.20 billion in the current year to USD 34.7 billion by 2040, at a CAGR of 28% during the forecast period, till 2040. The new study provides market size, growth scenarios, industry trends and future forecasts.

Artificial Intelligence (AI) is a subdivision of computer science that enables computers to perform intricate tasks that usually require human intelligence, including learning, reasoning, and making decisions. In the healthcare sector, AI is already being applied in various areas such as drug discovery, clinical trials, diagnostics, personalized medicine, and data management. Within pharmaceutical manufacturing, AI utilizes technologies like computer vision, machine learning, generative AI, and deep learning to improve process monitoring, identify inefficiencies, lower production costs, and enhance product yield.

Pharmaceutical manufacturing faces numerous inefficiencies, including inefficient workflows, equipment downtime, quality control issues, and supply chain interruptions. These inefficiencies can result in higher costs, production delays, and variability in product quality. AI addresses these challenges by enabling process optimization, monitoring the performance of plants and equipment, anticipating equipment failures beforehand, managing supply chains, and automating quality control processes. Several pharmaceutical companies, including Pfizer, Moderna, Novartis, Merck, and Sanofi, are integrating AI into their manufacturing operations as the sector evolves towards Pharma 4.0.

Strategic Insights for Senior Leaders

What are the Use Cases of Artificial Intelligence in Pharmaceutical Manufacturing?

More than 60% of major pharmaceutical companies are utilizing AI to revolutionize their manufacturing processes, improving efficiency, quality, and flexibility. Prominent applications include real-time monitoring, automated quality inspections, predictive maintenance, and optimization of the supply chain.

For example, Sanofi applies AI to enhance production yield and process effectiveness; Novartis uses machine learning techniques for real-time monitoring of plants and AI-powered supply chain optimization in drug production; Merck utilizes AI to decrease false reject rates in quality assessments; and Moderna leverages AI-based tools to improve quality control systems. These technologies not only streamline processes but also lead to cost savings and a better regulatory environment for AI in the drug manufacturing sector.

As top pharmaceutical firms and AI solution providers continue to develop their capabilities, incorporating AI into drug manufacturing has become essential for achieving operational excellence and sustaining a competitive advantage in this swiftly changing industry.

Key Drivers Propelling Growth of AI in Pharma Manufacturing Market

The growth of AI in the drug manufacturing sector is driven by an increasing demand for enhanced process efficiency, lower production costs, and the maintenance of consistent product quality. Additionally, rising regulatory support and the ongoing digital transformation within the pharmaceutical industry further promotes the adoption of cutting-edge AI technologies.

It is worth noting that AI applications in drug manufacturing encompass a range of functions, including quality control, predictive maintenance, process development and optimization, monitoring of plant and equipment performance, as well as supply chain optimization. The broadening range of these applications continues to propel substantial market demand for AI solutions specifically designed for pharmaceutical manufacturing.

AI in Pharma Manufacturing Market: Competitive Landscape of Companies in this Industry

The present market environment consists of approximately 130 participants, including major, large, medium, and small enterprises. These organizations possess the necessary skills to deliver AI solutions for drug production across various geographical areas.

Importantly, over 95% of the companies involved in AI for drug production provide advanced software solutions. Further, nearly 80% of these firms are implementing machine learning to digitize various phases of the drug manufacturing process.

Regional Analysis: Asia-Pacific to Propel the market growth in the Coming Years

According to our projections, currently North America captures the majority of the market, and this trend is unlikely to change in the future as well. This is due to the presence of advanced pharma manufacturing infrastructure, early adoption of artificial intelligence (AI) in healthcare technologies and supportive regulatory framework across the region.

However, it is worth highlighting that the market in Asia-Pacific is expected to grow at a higher CAGR during the forecast period. This is driven by the lower implementation costs, supportive government policies fostering digitalization, and rapidly expanding pharmaceutical sector.

AI in Pharma Manufacturing Evolution: Emerging Trends in the Industry

AI is transforming pharmaceutical manufacturing by making processes smarter, faster, and more reliable. Emerging trends include predictive maintenance using machine learning to spot equipment issues early, cutting downtime and costs. Real-time quality control with AI vision detects defects like cracks or contamination instantly in production lines, ensuring consistent drug quality and regulatory compliance. Process optimization employs advanced controls and digital twins to fine-tune parameters such as temperature and mixing, boosting efficiency and reducing waste. AI combined with robotics and IoT enables automated labs of the future for continuous monitoring and adaptive production. These innovations help pharma companies to produce safer medicines quicker while saving money and meeting strict standards.

Key Market Challenges

The market for AI in pharma manufacturing faces significant challenges that slow its adoption. One of the primary challenges is data issues, with poor quality, biases, silos, and limited availability making AI models unreliable for precise production tasks. High costs for setup, integration with old systems, and ongoing maintenance strain budgets, especially for smaller firms hindering the adoption of such technologies. Additionally, strict regulations like GMP and FDA rules demand validation, transparency, and compliance, but AI's "black box" nature complicates approvals and ethics. Moreover, shortage of personnel skilled in both AI and pharmaceutical expertise hampers effective deployment of AI in the pharmaceutical manufacturing domain.

AI in Pharma Manufacturing Market: Key Market Segmentation

Type of Offering

- Hardware

- Software

- Services

Mode of Deployment

- Cloud

- On-premise

Type of AI Solution

- Standard / Off-the-shelf AI solutions

- Personalized AI solutions

Type of Technology

- Computer Vision

- Deep Learning

- Generative AI

- Machine Learning

- Other Technologies

Application Area

- Process Development and Optimization

- Plant / Equipment Performance Monitoring

- Predictive Maintenance

- Quality Control

- Supply Chain Optimization

- Other Application Areas

Utility in Drug Manufacturing

- Defect Detection

- Packaging and Label Inspection

- Package Counting

- Fill Level Inspection

- Other Utilities

Geographical Regions

- North America

- US

- Canada

- Europe

- Germany

- UK

- Italy

- Spain

- France

- Rest of Europe

- Asia-Pacific

- China

- India

- Japan

- Korea

- Australia

- Latin America

- Brazil

- Argentina

- Rest of Latin America

- Middle East and North Africa

- Saudi Arabia

- UAE

- Egypt

- Rest of MENA

AI in Pharma Manufacturing Market: Key Market Share Insights

Market Share by Type of Offering

Based on the type of offering, the global market is segmented into hardware, software, and services. According to our estimates, currently, software captures majority share of the market. This is driven by the increasing adoption of software-based solutions that integrate advanced techniques, such as predictive analytics, and process optimization, thereby improving operational efficiency and foster innovation in drug manufacturing.

Market Share by Type of AI Solution

Based on the type of AI solution, the global market is segmented into standard / off-the-shelf AI solutions and personalized AI solutions. According to our estimates, currently, standard / off-the-shelf AI solutions capture majority share of the market. This is primarily due to industry's preference towards pre-validated, compliant, and ready-to-deploy solutions that can be deployed and scaled rapidly.

Example Players in AI in Pharma Manufacturing Market

- C3.AI

- AMD

- IBM

- Kalypso

- SAS Institute

- Korber Pharma

- SDG Group

- Catalyx

- Elisa Industriq

- Straive

- Axiomtek

- Appinventiv

- Amplelogic

- Precognize

AI in Pharma Manufacturing Market: Report Coverage

The report on the AI in pharma manufacturing market features insights on various sections, including:

- Market Sizing and Opportunity Analysis: An in-depth analysis of the AI in pharma manufacturing market, focusing on key market segments, including [A] type of offering, [B] mode of deployment, [C] type of AI solution, [D] type of technology, [E] application area, [F] utility in drug manufacturing, [G] geographical regions and [H] key players.

- Competitive Landscape: A comprehensive analysis of the companies engaged in the AI in pharma manufacturing market, based on several relevant parameters, such as [A] year of establishment, [B] company size, [C] location of headquarters and [D] ownership structure.

- Company Profiles: Elaborate profiles of prominent players engaged in the AI in pharma manufacturing market, providing details on [A] location of headquarters, [B] company size, [C] company mission, [D] company footprint, [E] management team, [F] contact details, [G] financial information, [H] operating business segments, [I] portfolio, [J] recent developments, and an informed future outlook.

- Megatrends: An evaluation of ongoing megatrends in the AI in pharma manufacturing industry.

- Recent Developments: An overview of the recent developments made in the AI in pharma manufacturing market, along with analysis based on relevant parameters, including [A] year of initiative, [B] type of initiative, [C] geographical distribution and [D] most active players.

- SWOT Analysis: An insightful SWOT framework, highlighting the strengths, weaknesses, opportunities and threats in the domain. Additionally, it provides Harvey ball analysis, highlighting the relative impact of each SWOT parameter.

Key Questions Answered in this Report

- What is the current and future market size?

- Who are the leading companies in this market?

- What are the growth drivers that are likely to influence the evolution of this market?

- What are the key partnership and funding trends shaping this industry?

- Which region is likely to grow at higher CAGR till 2040?

- How is the current and future market opportunity likely to be distributed across key market segments?

Reasons to Buy this Report

- Detailed Market Analysis: The report provides a comprehensive market analysis, offering detailed revenue projections of the overall market and its specific sub-segments. This information is valuable to both established market leaders and emerging entrants.

- In-depth Analysis of Trends: Stakeholders can leverage the report to gain a deeper understanding of the competitive dynamics within the market. Each report maps ecosystem activity across partnerships, funding, and patent landscapes to reveal growth hotspots and white spaces in the industry.

- Opinion of Industry Experts: The report features extensive interviews and surveys with key opinion leaders and industry experts to validate market trends mentioned in the report.

- Decision-ready Deliverables: The report offers stakeholders with strategic frameworks (Porter's Five Forces, value chain, SWOT), and complimentary Excel / slide packs with customization support.

Additional Benefits

- Complimentary Dynamic Excel Dashboards for Analytical Modules

- Exclusive 15% Free Content Customization

- Personalized Interactive Report Walkthrough with Our Expert Research Team

- Free Report Updates for Versions Older than 6-12 Months

TABLE OF CONTENTS

1. BACKGROUND

- 1.1. Context

- 1.2. Project Objectives

2. RESEARCH METHODOLOGY

- 2.1. Chapter Overview

- 2.2. Research Assumptions

- 2.2.1. Market Landscape and Market Trends

- 2.2.2. Market Forecast and Opportunity Analysis

- 2.2.3. Comparative Analysis

- 2.3. Database Building

- 2.3.1. Project Commencement

- 2.3.2. Data Collection

- 2.3.3. Data Validation

- 2.3.4. Data Analysis

- 2.4. Project Methodology

- 2.4.1. Secondary Research

- 2.4.1.1. Annual Reports

- 2.4.1.2. Academic Research Papers

- 2.4.1.3. Company Websites

- 2.4.1.4. Investor Presentations

- 2.4.1.5. Regulatory Filings

- 2.4.1.6. White Papers

- 2.4.1.7. Industry Publications

- 2.4.1.8. Conferences and Seminars

- 2.4.1.9. Government Portals

- 2.4.1.10. Media and Press Releases

- 2.4.1.11. Newsletters

- 2.4.1.12. Industry Databases

- 2.4.1.13. Roots Proprietary Databases

- 2.4.1.14. Paid Databases and Sources

- 2.4.1.15. Social Media Portals

- 2.4.1.16. Other Secondary Sources

- 2.4.2. Primary Research

- 2.4.2.1. Types of Primary Research

- 2.4.2.1.1. Qualitative Research

- 2.4.2.1.2. Quantitative Research

- 2.4.2.1.3. Hybrid Approach

- 2.4.2.2. Advantages of Primary Research

- 2.4.2.3. Techniques for Primary Research

- 2.4.2.3.1. Interviews

- 2.4.2.3.2. Surveys

- 2.4.2.3.3. Focus Groups

- 2.4.2.3.4. Observational Research

- 2.4.2.3.5. Social Media Interactions

- 2.4.2.4. Key Opinion Leaders Considered in Primary Research

- 2.4.2.4.1. Company Executives (CXOs)

- 2.4.2.4.2. Board of Directors

- 2.4.2.4.3. Company Presidents and Vice Presidents

- 2.4.2.4.4. Research and Development Heads

- 2.4.2.4.5. Technical Experts

- 2.4.2.4.6. Subject Matter Experts

- 2.4.2.4.7. Scientists

- 2.4.2.4.8. Doctors and Other Healthcare Providers

- 2.4.2.5. Ethics and Integrity

- 2.4.2.5.1. Research Ethics

- 2.4.2.5.2. Data Integrity

- 2.4.2.1. Types of Primary Research

- 2.4.3. Analytical Tools and Databases

- 2.4.1. Secondary Research

- 2.5. Robust Quality Control

3. MARKET DYNAMICS

- 3.1. Chapter Overview

- 3.2. Forecast Methodology

- 3.2.1. Top-down Approach

- 3.2.2. Bottom-up Approach

- 3.2.3. Hybrid Approach

- 3.3. Market Assessment Framework

- 3.3.1. Total Addressable Market (TAM)

- 3.3.2. Serviceable Addressable Market (SAM)

- 3.3.3. Serviceable Obtainable Market (SOM)

- 3.3.4. Currently Acquired Market (CAM)

- 3.4. Forecasting Tools and Techniques

- 3.4.1. Qualitative Forecasting

- 3.4.2. Correlation

- 3.4.3. Regression

- 3.4.4. Extrapolation

- 3.4.5. Convergence

- 3.4.6. Sensitivity Analysis

- 3.4.7. Scenario Planning

- 3.4.8. Data Visualization

- 3.4.9. Time Series Analysis

- 3.4.10. Forecast Error Analysis

- 3.5. Key Considerations

- 3.5.1. Demographics

- 3.5.2. Government Regulations

- 3.5.3. Reimbursement Scenarios

- 3.5.4. Market Access

- 3.5.5. Supply Chain

- 3.5.6. Industry Consolidation

- 3.5.7. Pandemic / Unforeseen Disruptions Impact

- 3.6. Limitations

4. MACRO-ECONOMIC INDICATORS

- 4.1. Chapter Overview

- 4.2. Market Dynamics

- 4.2.1. Time Period

- 4.2.1.1. Historical Trends

- 4.2.1.2. Current and Forecasted Estimates

- 4.2.2. Currency Coverage

- 4.2.2.1. Major Currencies Affecting the Market

- 4.2.2.2. Factors Affecting Currency Fluctuations on the Industry

- 4.2.2.3. Impact of Currency Fluctuations on the Industry

- 4.2.3. Foreign Currency Exchange Rate

- 4.2.3.1. Impact of Foreign Exchange Rate Volatility on the Market

- 4.2.3.2. Strategies for Mitigating Foreign Exchange Risk

- 4.2.4. Recession

- 4.2.4.1. Assessment of Current Economic Conditions and Potential Impact on the Market

- 4.2.4.2. Historical Analysis of Past Recessions and Lessons Learnt

- 4.2.5. Inflation

- 4.2.5.1. Measurement and Analysis of Inflationary Pressures in the Economy

- 4.2.5.2. Potential Impact of Inflation on the Market Evolution

- 4.2.6. Interest Rates

- 4.2.6.1. Interest Rates and Their Impact on the Market

- 4.2.6.2. Strategies for Managing Interest Rate Risk

- 4.2.7. Commodity Flow Analysis

- 4.2.7.1. Type of Commodity

- 4.2.7.2. Origins and Destinations

- 4.2.7.3. Values and Weights

- 4.2.7.4. Modes of Transportation

- 4.2.8. Global Trade Dynamics

- 4.2.8.1. Import Scenario

- 4.2.8.2. Export Scenario

- 4.2.8.3. Trade Policies

- 4.2.8.4. Strategies for Mitigating the Risks Associated with Trade Barriers

- 4.2.8.5. Impact of Trade Barriers on the Market

- 4.2.9. War Impact Analysis

- 4.2.9.1. Russian-Ukraine War

- 4.2.9.2. Israel-Hamas War

- 4.2.10. COVID Impact / Related Factors

- 4.2.10.1. Global Economic Impact

- 4.2.10.2. Industry-specific Impact

- 4.2.10.3. Government Response and Stimulus Measures

- 4.2.10.4. Future Outlook and Adaptation Strategies

- 4.2.11. Other Indicators

- 4.2.11.1. Fiscal Policy

- 4.2.11.2. Consumer Spending

- 4.2.11.3. Gross Domestic Product

- 4.2.11.4. Employment

- 4.2.11.5. Taxes

- 4.2.11.6. Stock Market Performance

- 4.2.11.7. Cross Border Dynamics

- 4.2.1. Time Period

- 4.3. Conclusion

5. EXECUTIVE SUMMARY

6. INTRODUCTION

- 6.1. Overview of AI in Pharma Manufacturing

- 6.2. Need for AI in Pharma Manufacturing

- 6.3. Role of AI across the Drug Manufacturing Value Chain

- 6.4. Types of AI Technology used in Drug Manufacturing

- 6.5. Applications of AI in Pharma Manufacturing

- 6.6. Advantages of AI in Pharma Manufacturing

- 6.7. Challenges Associated with AI Adoption in Drug Manufacturing

- 6.8. Recent Developments and Future Perspectives

7. MARKET LANDSCAPE: AI IN PHARMA MANUFACTURING SOLUTION PROVIDERS

- 7.1. Methodology and Key Parameters

- 7.2. AI in Pharma Manufacturing: Market Landscape

- 7.2.1. Analysis by Year of Establishment

- 7.2.2. Analysis by Company Size

- 7.2.3. Analysis by Location of Headquarters (Region)

- 7.2.4. Analysis by Location of Headquarters (Country)

- 7.2.5. Analysis by Company Ownership

- 7.2.6. Analysis by Type of Company

- 7.2.7. Analysis by Type of AI Solution

- 7.2.8. Analysis by Type of Offering

- 7.2.9. Analysis by Type of Technology

- 7.2.10. Analysis by Mode of Deployment

- 7.2.11. Analysis by Application Area

- 7.2.12. Analysis by Utility in Drug Manufacturing

8. COMPANY COMPETITIVENESS ANALYSIS

- 8.1. Methodology and Key Parameters

- 8.2. Scoring Criteria

- 8.3. Overview of Peer Groups

- 8.4. AI in Pharma Manufacturing: Company Competitiveness Analysis

- 8.4.1. AI in Pharma Manufacturing Solution Providers in North America: Peer Group I

- 8.4.1.1. Leading Players in Peer Group I

- 8.4.2. AI in Pharma Manufacturing Solution Providers in Europe: Peer Group II

- 8.4.2.1. Leading Players in Peer Group II

- 8.4.3. AI in Pharma Manufacturing Solution Providers in Asia-Pacific and Rest of the World: Peer Group III

- 8.4.3.1. Leading Players in Peer Group III

- 8.4.1. AI in Pharma Manufacturing Solution Providers in North America: Peer Group I

- 8.5. AI in Pharma Manufacturing: Benchmarking Analysis

- 8.5.1. Benchmarking based on Supplier Strength Score

- 8.5.2. Benchmarking based on Technology Strength Score

- 8.5.3. Benchmarking based on Application Diversity Score

9. COMPANY PROFILES: AI IN PHARMA MANUFACTURING SOLUTION PROVIDERS IN NORTH AMERICA

- 9.1. Overview

- 9.2. C3.AI

- 9.2.1. Company Details

- 9.2.2. Technology Portfolio

- 9.2.3. Financial Information

- 9.2.4. SWOT Analysis

- 9.2.5. Strategic Framework

- 9.2.6. Future Outlook

- 9.3. AMD

- 9.4. IBM

- 9.5. Kalypso: A Rockwell Automation Business

- 9.6. SAS Institute

10. COMPANY PROFILES: AI IN PHARMA MANUFACTURING SOLUTION PROVIDERS IN EUROPE

- 10.1. Overview

- 10.2. Korber Pharma

- 10.2.1. Company Details

- 10.2.2. Technology Portfolio

- 10.2.3. Financial Information

- 10.2.4. SWOT Analysis

- 10.2.5. Strategic Framework

- 10.2.6. Future Outlook

- 10.3. SDG Group

- 10.4. Catalyx

- 10.5. Elisa Industriq

11. COMPANY PROFILES: AI IN PHARMA MANUFACTURING SOLUTION PROVIDERS IN ASIA-PACIFIC AND REST OF THE WORLD

- 11.1. Overview

- 11.2. Straive

- 11.2.1. Company Details

- 11.2.2. Technology Portfolio

- 11.2.3. SWOT Analysis

- 11.2.4. Strategic Framework

- 11.2.5. Future Outlook

- 11.3. Axiomtek

- 11.4. Appinventiv

- 11.5. Amplelogic

- 11.6. Samson Precognize Solutions

12. PARTNERSHIPS AND COLLABORATIONS

- 12.1. Partnership Models

- 12.2. AI in Pharma Manufacturing: Partnerships and Collaborations

- 12.2.1. Analysis by Year of Partnership

- 12.2.2. Analysis by Type of Partnership

- 12.2.3. Analysis by Year and Type of Partnership

- 12.2.4. Analysis by Type of Partner

- 12.2.5. Analysis by Geographical Activity

- 12.2.5.1. Local and International Deals

- 12.2.5.2. Intracontinental and Intercontinental Deals

- 12.2.6. Most Active Players: Analysis by Number of Partnerships

13. FUNDING AND INVESTMENT ANALYSIS

- 13.1. Funding Models

- 13.2. Funding Lifecycle Analysis

- 13.3. Investment Case: Risk and Return

- 13.4. AI in Pharma Manufacturing: Funding and Investment Analysis

- 13.4.1. Analysis of Instances by Year of Funding

- 13.4.2. Analysis of Instances by Type of Funding

- 13.4.3. Analysis of Instances by Year and Type of Funding

- 13.4.4. Analysis of Amount Raised by Year of funding

- 13.4.5. Analysis of Amount Raised by Type of Funding

- 13.4.6. Analysis by Geography

- 13.4.7. Most Active Players: Analysis by Number of Funding Instances

- 13.4.8. Most Active Players: Analysis by Amount Raised

- 13.4.9. Leading Investors: Analysis by Number of Funding Instances

- 13.5. Evolution and Relative Assessment of Funding Models

- 13.5.1. Grants / Awards

- 13.5.2. Venture Capital

- 13.5.3. Private Placement

- 13.6. Summary of Funding and Investment Opportunities

14. START-UP HEALTH INDEXING

- 14.1. Chapter Overview

- 14.2. Start-ups Offering AI Solutions for Drug Manufacturing

- 14.2.1. Analysis by Location of Headquarters

- 14.3. Benchmarking of Start-ups

- 14.3.1. Analysis by Technology Strength

- 14.3.2. Analysis by Application Diversity

- 14.3.3. Analysis by Utility in Drug Manufacturing

- 14.3.4. Analysis by Funding Activity

- 14.3.5. Analysis by Revenue

- 14.3.6. Start-up Health Indexing: Roots Analysis Perspective

15. AI IN PHARMA MANUFACTURING MARKET: MEGATRENDS ANALYSIS

- 15.1. Megatrends Analysis: An Overview of Emerging Trends

- 15.1.1. Pharma 4.0 Adoption

- 15.1.2. Increasing Emphasis on Regulatory Compliance

- 15.1.3. Transition towards Continuous Manufacturing

- 15.1.4. Digitization of Batch Records and Manufacturing Documentation

- 15.1.5. Shift towards Predictive Maintenance Approach

- 15.1.6. Rise in Strategic Collaborations and Investments

16. MARKET IMPACT ANALYSIS: DRIVERS, RESTRAINTS, OPPORTUNITIES AND CHALLENGES

- 16.1. Chapter Overview

- 16.2. Market Drivers

- 16.3. Market Restraints

- 16.4. Market Opportunities

- 16.5. Market Challenges

- 16.6. Conclusion

17. GLOBAL AI IN PHARMA MANUFACTURING MARKET

- 17.1. Methodology

- 17.2. AI in Pharma Manufacturing Market, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 17.2.1. Multivariate Scenario Analysis

- 17.2.1.1. Conservative Scenario

- 17.2.1.2. Optimistic Scenario

- 17.2.1. Multivariate Scenario Analysis

- 17.3. Key Market Segmentations

- 17.4. Key Assumptions and Data Validation

18. AI in Pharma Manufacturing MARKET, BY tYPE OF OFFERINg

- 18.1. Methodology

- 18.2. AI in Pharma Manufacturing Market: Distribution by Type of Offering

- 18.2.1. AI in Pharma Manufacturing Market for Software, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 18.2.2. AI in Pharma Manufacturing Market for Hardware, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 18.2.3. AI in Pharma Manufacturing Market for Services, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 18.3. Data Triangulation and Validation

19. AI IN PHARMA MANUFACTURING MARKET, BY MODe of deployment

- 19.1. Methodology

- 19.2. AI in Pharma Manufacturing Market: Distribution by Mode of Deployment

- 19.2.1. AI in Pharma Manufacturing Market for Cloud-based Solutions, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 19.2.2. AI in Pharma Manufacturing Market for On-premise Solutions, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 19.3. Data Triangulation and Validation

20. AI IN PHARMA MANUFACTURING MARKET, BY TYPE OF AI solution

- 20.1. Methodology

- 20.2. AI in Pharma Manufacturing Market: Distribution by Type of AI Solution

- 20.2.1. AI in Pharma Manufacturing Market for Off-the-Shelf AI Solutions, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 20.2.2. AI in Pharma Manufacturing Market for Personalized AI Solutions, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 20.3. Data Triangulation and Validation

21. AI IN PHARMA MANUFACTURING MARKET, BY TYPE OF Technology

- 21.1. Methodology

- 21.2. AI in Pharma Manufacturing Market: Distribution by Type of Technology

- 21.2.1. AI in Pharma Manufacturing Market for Computer Vision, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 21.2.2. AI in Pharma Manufacturing Market for Machine Learning, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 21.2.3. AI in Pharma Manufacturing Market for Deep Learning, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 21.2.4. AI in Pharma Manufacturing Market for Generative AI, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 21.2.5. AI in Pharma Manufacturing Market for Other Technologies, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 21.3. Data Triangulation and Validation

22. AI IN PHARMA MANUFACTURING MARKET, BY Application AREA

- 22.1. Methodology

- 22.2. AI in Pharma Manufacturing Market: Distribution by Application Area

- 22.2.1. AI in Pharma Manufacturing Market for Quality Control, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 22.2.2. AI in Pharma Manufacturing Market for Predictive Maintenance, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 22.2.3. AI in Pharma Manufacturing Market for Process Development and Optimization, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 22.2.4. AI in Pharma Manufacturing Market for Plant or Equipment Performance Monitoring, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 22.2.5. AI in Pharma Manufacturing Market for Supply Chain Optimization, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 22.2.6. AI in Pharma Manufacturing Market for Other Application Areas, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 22.3. Data Triangulation and Validation

23. AI IN PHARMA MANUFACTURING MARKET, BY Utility in Drug Manufacturing

- 23.1. Methodology

- 23.2. AI in Pharma Manufacturing Market: Distribution by Utility in Drug Manufacturing

- 23.2.1. AI in Pharma Manufacturing Market for Defect Detection, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 23.2.2. AI in Pharma Manufacturing Market for Packaging and Label Inspection, Historical Trends (since 2023) and Forecasted Estimates (till 2040)

- 23.2.3. AI in Pharma Manufacturing Market for Package Counting, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 23.2.4. AI in Pharma Manufacturing Market for Fill Level Inspection, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 23.2.5. AI in Pharma Manufacturing Market for Other Utilities, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 23.3. Data Triangulation and Validation

24. AI IN PHARMA MANUFACTURING MARKET, BY Geographical Regions

- 24.1. Methodology

- 24.2. AI in Pharma Manufacturing Market: Distribution by Geographical Regions

- 24.2.1. AI in Pharma Manufacturing Market in North America, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 24.2.1.1. AI in Pharma Manufacturing Market in the US, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 24.2.1.2. AI in Pharma Manufacturing Market in Canada, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 24.2.2. AI in Pharma Manufacturing Market in Europe, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 24.2.2.1. AI in Pharma Manufacturing Market in Germany, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 24.2.2.2. AI in Pharma Manufacturing Market in France, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 24.2.2.3. AI in Pharma Manufacturing Market in Spain, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 24.2.2.4. AI in Pharma Manufacturing Market in Italy, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 24.2.2.5. AI in Pharma Manufacturing Market in the UK, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 24.2.2.6. AI in Pharma Manufacturing Market in the Rest of Europe, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 24.2.3. AI in Pharma Manufacturing Market in Asia-Pacific, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 24.2.3.1. AI in Pharma Manufacturing Market in Australia, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 24.2.3.2. AI in Pharma Manufacturing Market in China, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 24.2.3.3. AI in Pharma Manufacturing Market in Japan, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 24.2.3.4. AI in Pharma Manufacturing Market in India, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 24.2.3.5. AI in Pharma Manufacturing Market in South Korea, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 24.2.3.6. AI in Pharma Manufacturing Market in the Rest of Asia-Pacific, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 24.2.4. AI in Pharma Manufacturing Market in the Middle East and North Africa, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 24.2.4.1. AI in Pharma Manufacturing Market in Saudi Arabia, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 24.2.4.2. AI in Pharma Manufacturing Market in UAE, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 24.2.4.3. AI in Pharma Manufacturing Market in Egypt, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 24.2.4.4. AI in Pharma Manufacturing Market in the Rest of Middle East and North Africa, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 24.2.5. AI in Pharma Manufacturing Market in Latin America, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 24.2.5.1. AI in Pharma Manufacturing Market in Brazil, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 24.2.5.2. AI in Pharma Manufacturing Market in Argentina, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 24.2.5.3. AI in Pharma Manufacturing Market in the Rest of Latin America, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 24.2.1. AI in Pharma Manufacturing Market in North America, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 24.3. AI in Pharma Manufacturing Market, By Geographical Regions: Market Dynamics Assessment

- 24.3.1. Penetration-Growth (P-G) Matrix

- 24.3.2. Market Movement Analysis

25. AI IN PHARMA MANUFACTURING MARKET, BY KEY Players

26. MARKET OPPORTUNITY ANALYSIS: NORTH AMERICA

- 26.1. AI in Pharma Manufacturing Market in North America: Distribution by Type of Offering

- 26.1.1. AI in Pharma Manufacturing Market in North America for Software, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 26.1.2. AI in Pharma Manufacturing Market in North America for Hardware, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 26.1.3. AI in Pharma Manufacturing Market in North America for Services, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 26.2. AI in Pharma Manufacturing Market in North America: Distribution by Type of AI Solution

- 26.2.1. AI in Pharma Manufacturing Market in North America for Off-the-Shelf AI Solutions, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 26.2.2. AI in Pharma Manufacturing Market in North America for Personalized AI Solutions, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 26.3. AI in Pharma Manufacturing Market in North America: Distribution by Mode of Deployment

- 26.3.1. AI in Pharma Manufacturing Market in North America Cloud-based Solutions, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 26.3.2. AI in Pharma Manufacturing Market in North America for On-premise Solutions, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 26.4. AI in Pharma Manufacturing Market in North America: Distribution by Type of Technology

- 26.4.1. AI in Pharma Manufacturing Market in North America for Computer Vision, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 26.4.2. AI in Pharma Manufacturing Market in North America for Machine Learning, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 26.4.3. AI in Pharma Manufacturing Market in North America for Deep Learning, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 26.4.4. AI in Pharma Manufacturing Market in North America for Generative AI, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 26.4.5. AI in Pharma Manufacturing Market in North America for Other Technologies, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 26.5. AI in Pharma Manufacturing Market in North America: Distribution by Application Area

- 26.5.1. AI in Pharma Manufacturing Market in North America for Quality Control, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 26.5.2. AI in Pharma Manufacturing Market in North America for Predictive Maintenance, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 26.5.3. AI in Pharma Manufacturing Market in North America for Process Development and Optimization, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 26.5.4. AI in Pharma Manufacturing Market in North America for Supply Chain Optimization, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 26.5.5. AI in Pharma Manufacturing Market in North America for Other Application Areas, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 26.6. AI in Pharma Manufacturing Market in North America: Distribution by Utility in Drug Manufacturing

- 26.6.1. AI in Pharma Manufacturing Market in North America for Defect Detection, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 26.6.2. AI in Pharma Manufacturing Market in North America for Packaging and Label Inspection, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 26.6.3. AI in Pharma Manufacturing Market in North America for Package Counting, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 26.6.4. AI in Pharma Manufacturing Market in North America for Fill Level Inspection, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 26.6.5. AI in Pharma Manufacturing Market in North America for Other Utilities, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

27. MARKET OPPORTUNITY ANALYSIS: EUROPE

- 27.1. AI in Pharma Manufacturing Market in Europe: Distribution by Type of Offering

- 27.1.1. AI in Pharma Manufacturing Market in Europe for Software, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 27.1.2. AI in Pharma Manufacturing Market in Europe for Hardware, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 27.1.3. AI in Pharma Manufacturing Market in Europe for Services, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 27.2. AI in Pharma Manufacturing Market in Europe: Distribution by Type of AI Solution

- 27.2.1. AI in Pharma Manufacturing Market in Europe for Off-the-Shelf AI Solutions, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 27.2.2. AI in Pharma Manufacturing Market in Europe for Personalized AI Solutions, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 27.3. AI in Pharma Manufacturing Market in Europe: Distribution by Mode of Deployment

- 27.3.1. AI in Pharma Manufacturing Market in Europe Cloud-based Solutions, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 27.3.2. AI in Pharma Manufacturing Market in Europe for On-premise Solutions, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 27.4. AI in Pharma Manufacturing Market in Europe: Distribution by Type of Technology

- 27.4.1. AI in Pharma Manufacturing Market in Europe for Computer Vision, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 27.4.2. AI in Pharma Manufacturing Market in Europe for Machine Learning, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 27.4.3. AI in Pharma Manufacturing Market in Europe for Deep Learning, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 27.4.4. AI in Pharma Manufacturing Market in Europe for Generative AI, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 27.4.5. AI in Pharma Manufacturing Market in Europe for Other Technologies, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 27.5. AI in Pharma Manufacturing Market in Europe: Distribution by Application Area

- 27.5.1. AI in Pharma Manufacturing Market in Europe for Quality Control, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 27.5.2. AI in Pharma Manufacturing Market in Europe for Predictive Maintenance, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 27.5.3. AI in Pharma Manufacturing Market in Europe for Process Development and Optimization, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 27.5.4. AI in Pharma Manufacturing Market in Europe for Supply Chain Optimization, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 27.5.5. AI in Pharma Manufacturing Market in Europe for Other Application Areas, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 27.6. AI in Pharma Manufacturing Market in Europe: Distribution by Utility in Drug Manufacturing

- 27.6.1. AI in Pharma Manufacturing Market in Europe for Defect Detection, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 27.6.2. AI in Pharma Manufacturing Market in Europe for Packaging and Label Inspection, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 27.6.3. AI in Pharma Manufacturing Market in Europe for Package Counting, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 27.6.4. AI in Pharma Manufacturing Market in Europe for Fill Level Inspection, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 27.6.5. AI in Pharma Manufacturing Market in Europe for Other Utilities, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

28. MARKET OPPORTUNITY ANALYSIS: ASIA-PACIFIC

- 28.1. AI in Pharma Manufacturing Market in Asia-Pacific: Distribution by Type of Offering

- 28.1.1. AI in Pharma Manufacturing Market in Asia-Pacific for Software, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 28.1.2. AI in Pharma Manufacturing Market in Asia-Pacific for Hardware, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 28.1.3. AI in Pharma Manufacturing Market in Asia-Pacific for Services, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 28.2. AI in Pharma Manufacturing Market in Asia-Pacific: Distribution by Type of AI Solution

- 28.2.1. AI in Pharma Manufacturing Market in Asia-Pacific for Off-the-Shelf AI Solutions, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 28.2.2. AI in Pharma Manufacturing Market in Asia-Pacific for Personalized AI Solutions, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 28.3. AI in Pharma Manufacturing Market in Asia-Pacific: Distribution by Mode of Deployment

- 28.3.1. AI in Pharma Manufacturing Market in Asia-Pacific Cloud-based Solutions, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 28.3.2. AI in Pharma Manufacturing Market in Asia-Pacific for On-premise Solutions, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 28.4. AI in Pharma Manufacturing Market in Asia-Pacific: Distribution by Type of Technology

- 28.4.1. AI in Pharma Manufacturing Market in Asia-Pacific for Computer Vision, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 28.4.2. AI in Pharma Manufacturing Market in Asia-Pacific for Machine Learning, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 28.4.3. AI in Pharma Manufacturing Market in Asia-Pacific for Deep Learning, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 28.4.4. AI in Pharma Manufacturing Market in Asia-Pacific for Generative AI, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 28.4.5. AI in Pharma Manufacturing Market in Asia-Pacific for Other Technologies, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 28.5. AI in Pharma Manufacturing Market in Asia-Pacific: Distribution by Application Area

- 28.5.1. AI in Pharma Manufacturing Market in Asia-Pacific for Quality Control, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 28.5.2. AI in Pharma Manufacturing Market in Asia-Pacific for Predictive Maintenance, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 28.5.3. AI in Pharma Manufacturing Market in Asia-Pacific for Process Development and Optimization, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 28.5.4. AI in Pharma Manufacturing Market in Asia-Pacific for Supply Chain Optimization, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 28.5.5. AI in Pharma Manufacturing Market in Asia-Pacific for Other Application Areas, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 28.6. AI in Pharma Manufacturing Market in Asia-Pacific: Distribution by Utility in Drug Manufacturing

- 28.6.1. AI in Pharma Manufacturing Market in Asia-Pacific for Defect Detection, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 28.6.2. AI in Pharma Manufacturing Market in Asia-Pacific for Packaging and Label Inspection, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 28.6.3. AI in Pharma Manufacturing Market in Asia-Pacific for Package Counting, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 28.6.4. AI in Pharma Manufacturing Market in Asia-Pacific for Fill Level Inspection, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 28.6.5. AI in Pharma Manufacturing Market in Asia-Pacific for Other Utilities, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

29. MARKET OPPORTUNITY ANALYSIS: MIDDLE EAST AND NORTH AFRICA

- 29.1. AI in Pharma Manufacturing Market in Middle East and North Africa: Distribution by Type of Offering

- 29.1.1. AI in Pharma Manufacturing Market in Middle East and North Africa for Software, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 29.1.2. AI in Pharma Manufacturing Market in Middle East and North Africa for Hardware, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 29.1.3. AI in Pharma Manufacturing Market in Middle East and North Africa for Services, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 29.2. AI in Pharma Manufacturing Market in Middle East and North Africa: Distribution by Type of AI Solution

- 29.2.1. AI in Pharma Manufacturing Market in Middle East and North Africa for Off-the-Shelf AI Solutions, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 29.2.2. AI in Pharma Manufacturing Market in Middle East and North Africa for Personalized AI Solutions, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 29.3. AI in Pharma Manufacturing Market in Middle East and North Africa: Distribution by Mode of Deployment

- 29.3.1. AI in Pharma Manufacturing Market in Middle East and North Africa Cloud-based Solutions, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 29.3.2. AI in Pharma Manufacturing Market in Middle East and North Africa for On-premise Solutions, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 29.4. AI in Pharma Manufacturing Market in Middle East and North Africa: Distribution by Type of Technology

- 29.4.1. AI in Pharma Manufacturing Market in Middle East and North Africa for Computer Vision, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 29.4.2. AI in Pharma Manufacturing Market in Middle East and North Africa for Machine Learning, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 29.4.3. AI in Pharma Manufacturing Market in Middle East and North Africa for Deep Learning, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 29.4.4. AI in Pharma Manufacturing Market in Middle East and North Africa for Generative AI, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 29.4.5. AI in Pharma Manufacturing Market in Middle East and North Africa for Other Technologies, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 29.5. AI in Pharma Manufacturing Market in Middle East and North Africa: Distribution by Application Area

- 29.5.1. AI in Pharma Manufacturing Market in Middle East and North Africa for Quality Control, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 29.5.2. AI in Pharma Manufacturing Market in Middle East and North Africa for Predictive Maintenance, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 29.5.3. AI in Pharma Manufacturing Market in Middle East and North Africa for Process Development and Optimization, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 29.5.4. AI in Pharma Manufacturing Market in Middle East and North Africa for Supply Chain Optimization, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 29.5.5. AI in Pharma Manufacturing Market in Middle East and North Africa for Other Application Areas , Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 29.6. AI in Pharma Manufacturing Market in Middle East and North Africa: Distribution by Utility in Drug Manufacturing

- 29.6.1. AI in Pharma Manufacturing Market in Middle East and North Africa for Defect Detection, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 29.6.2. AI in Pharma Manufacturing Market in Middle East and North Africa for Packaging and Label Inspection, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 29.6.3. AI in Pharma Manufacturing Market in Middle East and North Africa for Package Counting, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 29.6.4. AI in Pharma Manufacturing Market in Middle East and North Africa for Fill Level Inspection, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 29.6.5. AI in Pharma Manufacturing Market in Middle East and North Africa for Other Utilities, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

30. MARKET OPPORTUNITY ANALYSIS: LATIN AMERICA

- 30.1. AI in Pharma Manufacturing Market in Latin America: Distribution by Type of Offering

- 30.1.1. AI in Pharma Manufacturing Market in Latin America for Software, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 30.1.2. AI in Pharma Manufacturing Market in Latin America for Hardware, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 30.1.3. AI in Pharma Manufacturing Market in Latin America for Services, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 30.2. AI in Pharma Manufacturing Market in Latin America: Distribution by Type of AI Solution

- 30.2.1. AI in Pharma Manufacturing Market in Latin America for Off-the-Shelf AI Solutions, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 30.2.2. AI in Pharma Manufacturing Market in Latin America for Personalized AI Solutions, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 30.3. AI in Pharma Manufacturing Market in Latin America: Distribution by Mode of Deployment

- 30.3.1. AI in Pharma Manufacturing Market in Latin America Cloud-based Solutions, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 30.3.2. AI in Pharma Manufacturing Market in Latin America for On-premise Solutions, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 30.4. AI in Pharma Manufacturing Market in Latin America: Distribution by Type of Technology

- 30.4.1. AI in Pharma Manufacturing Market in Latin America for Computer Vision, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 30.4.2. AI in Pharma Manufacturing Market in Latin America for Machine Learning, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 30.4.3. AI in Pharma Manufacturing Market in Latin America for Deep Learning, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 30.4.4. AI in Pharma Manufacturing Market in Latin America for Generative AI, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 30.4.5. AI in Pharma Manufacturing Market in Latin America for Other Technologies, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 30.5. AI in Pharma Manufacturing Market in Latin America: Distribution by Application Area

- 30.5.1. AI in Pharma Manufacturing Market in Latin America for Quality Control, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 30.5.2. AI in Pharma Manufacturing Market in Latin America for Predictive Maintenance, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 30.5.3. AI in Pharma Manufacturing Market in Latin America for Process Development and Optimization, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 30.5.4. AI in Pharma Manufacturing Market in Latin America for Supply Chain Optimization, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 30.5.5. AI in Pharma Manufacturing Market in Latin America for Other Application Areas, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 30.6. AI in Pharma Manufacturing Market in Latin America: Distribution by Utility in Drug Manufacturing

- 30.6.1. AI in Pharma Manufacturing Market in Latin America for Defect Detection, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 30.6.2. AI in Pharma Manufacturing Market in Latin America for Packaging and Label Inspection, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 30.6.3. AI in Pharma Manufacturing Market in Latin America for Package Counting, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 30.6.4. AI in Pharma Manufacturing Market in Latin America for Fill Level Inspection, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

- 30.6.5. AI in Pharma Manufacturing Market in Latin America for Other Utilities, Historical Trends (since 2021) and Forecasted Estimates (till 2040)

31. CONCLUDING INSIGHTS

32. EXECUTIVE INSIGHTS

33. TABULATED DATA

34. LIST OF COMPANIES AND ORGANIZATIONS