PUBLISHER: Global Market Insights Inc. | PRODUCT CODE: 1844360

PUBLISHER: Global Market Insights Inc. | PRODUCT CODE: 1844360

Metal Manufacturing Waste Heat Recovery System Market Opportunity, Growth Drivers, Industry Trend Analysis, and Forecast 2025 - 2034

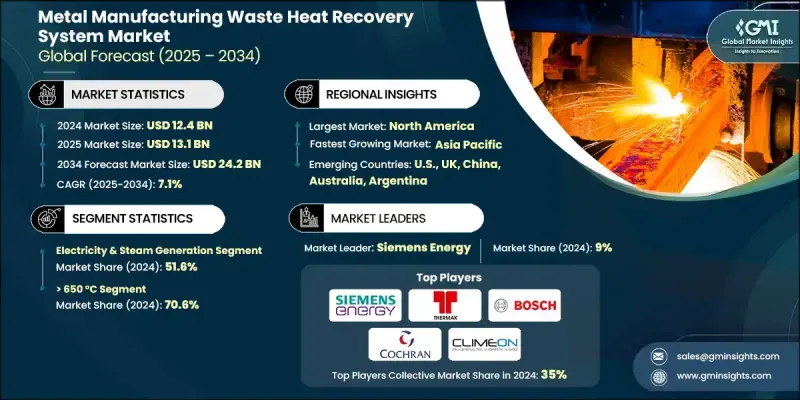

The Global Metal Manufacturing Waste Heat Recovery System Market was valued at USD 12.4 billion in 2024 and is estimated to grow at a CAGR of 7.1% to reach USD 24.2 billion by 2034.

The market continues to experience steady growth as manufacturers place greater emphasis on operational efficiency, sustainability, and reducing overall energy expenses. High-temperature processes such as rolling, forging, smelting, and casting generate large volumes of excess thermal energy. Waste heat recovery systems are engineered to capture this energy and convert it into usable forms such as electricity, steam, or process heat, reintegrating it into operations. This significantly reduces energy consumption, lowers emissions, and helps companies adhere to tightening environmental standards. With global regulatory bodies pushing for carbon reduction and clean production, the pressure is increasing on energy-intensive industries like metal manufacturing. These systems also help companies reduce reliance on primary energy inputs while advancing their sustainability goals. Recent improvements in heat exchanger technology, organic Rankine cycles, and thermoelectric materials have enhanced the performance and dependability of waste heat recovery systems, further supporting industry growth and long-term adoption.

| Market Scope | |

|---|---|

| Start Year | 2024 |

| Forecast Year | 2025-2034 |

| Start Value | $12.4 Billion |

| Forecast Value | $24.2 Billion |

| CAGR | 7.1% |

The electricity and steam generation accounted for a 51.6% share in 2024 and is projected to grow at a CAGR of 8.1% through 2034. Growing deployment of waste heat recovery systems (WHRS) within renewable initiatives and government-backed electrification efforts across emerging regions is accelerating the demand. The rising focus on repurposing industrial waste energy for power and steam applications is also positively influencing market momentum, particularly in infrastructure-challenged regions.

The temperatures above 650 °C segment held a 70.6% share in 2024 and is anticipated to grow at a CAGR of 7% by 2034. Systems designed for high-temperature applications are becoming increasingly critical, especially in direct recovery setups within smelting and casting lines. These systems recover heat directly from extreme exhaust streams, eliminating the need for additional heating stages and improving thermal efficiency. Their robust construction enables them to endure the high-dust and high-heat environments typically seen in converters and blast furnaces, making them ideal for continuous use in intensive industrial settings.

Europe Metal Manufacturing Waste Heat Recovery System Market is expected to grow at a CAGR of 6.6% through 2034, fueled by stringent environmental directives, evolving steel industry practices, and expanded investment in waste-to-energy infrastructure. These systems play a vital role in addressing the energy challenges of urban areas, facing rising utility costs and limited landfill availability, creating strong demand for advanced recovery solutions.

Companies leading the Global Metal Manufacturing Waste Heat Recovery System Market include Siemens Energy, IHI Corporation, Echogen Power Systems, Climeon, Thermax, Bosch, Promec Engineering, Kanin Energy, Mitsubishi Heavy Industries, AURA, Forbes Marshall, Turboden, CMR Green Technologies Ltd., FirstESCO India Pvt. Ltd., Kawasaki Heavy Industries, John Wood Group, Cochran, Primetals Technologies, Sofinter, and CTP TEAM. To enhance their presence, companies are focusing on strategic product development, cross-sector collaborations, and technological innovations. They are investing in more compact and high-efficiency recovery systems that meet a wide range of industrial requirements, including harsh environmental conditions and high-dust applications.

Table of Contents

Chapter 1 Methodology & Scope

- 1.1 Research design

- 1.2 Base estimates & calculations

- 1.3 Forecast calculation

- 1.4 Data sources

- 1.4.1 Primary

- 1.4.2 Secondary

- 1.4.2.1 Paid

- 1.4.2.2 Public

- 1.5 Market definitions

Chapter 2 Executive Summary

- 2.1 Industry synopsis, 2021 - 2034

Chapter 3 Industry Insights

- 3.1 Industry ecosystem analysis

- 3.2 Regulatory landscape

- 3.3 Industry impact forces

- 3.3.1 Growth drivers

- 3.3.2 Industry pitfalls & challenges

- 3.4 Growth potential analysis

- 3.5 Porter's analysis

- 3.5.1 Bargaining power of suppliers

- 3.5.2 Bargaining power of buyers

- 3.5.3 Threat of new entrants

- 3.5.4 Threat of substitutes

- 3.6 PESTEL analysis

- 3.6.1 Political factors

- 3.6.2 Economic factors

- 3.6.3 Social factors

- 3.6.4 Technology factors

- 3.6.5 environmental factors

- 3.6.6 Legal factors

- 3.7 Emerging opportunities & trends

- 3.7.1 Digitalization and IoT integration

- 3.7.2 Emerging market penetration

Chapter 4 Competitive landscape, 2025

- 4.1 Introduction

- 4.2 Company market share analysis, by region, 2024

- 4.2.1 North America

- 4.2.2 Europe

- 4.2.3 Asia Pacific

- 4.2.4 Middle East and Africa

- 4.2.5 Latin America

- 4.3 Strategic initiatives

- 4.4 Competitive benchmarking

- 4.5 Strategic dashboard

- 4.6 Innovation & technology landscape

Chapter 5 Market Size and Forecast, By Application, 2021 - 2034 (USD Million)

- 5.1 Key trends

- 5.2 Pre-heating

- 5.3 Electricity & steam generation

- 5.3.1 Steam rankine cycle

- 5.3.2 Organic rankine cycle

- 5.3.3 Kalina cycle

- 5.4 Others

Chapter 6 Market Size and Forecast, By Temperature, 2021 - 2034 (USD Million)

- 6.1 Key trends

- 6.2 < 230 °C

- 6.3 230°C - 650 °C

- 6.4 > 650 °C

Chapter 7 Market Size and Forecast, By Region, 2021 - 2034 (USD Million)

- 7.1 Key trends

- 7.2 North America

- 7.2.1 U.S.

- 7.2.2 Canada

- 7.2.3 Mexico

- 7.3 Europe

- 7.3.1 Germany

- 7.3.2 UK

- 7.3.3 France

- 7.3.4 Italy

- 7.3.5 Spain

- 7.4 Asia Pacific

- 7.4.1 China

- 7.4.2 Australia

- 7.4.3 India

- 7.4.4 Japan

- 7.4.5 South Korea

- 7.5 Middle East & Africa

- 7.5.1 Saudi Arabia

- 7.5.2 UAE

- 7.5.3 South Africa

- 7.6 Latin America

- 7.6.1 Brazil

- 7.6.2 Argentina

Chapter 8 Company Profiles

- 8.1 AURA

- 8.2 Bosch

- 8.3 Climeon

- 8.4 CMR Green Technologies Ltd.

- 8.5 Cochran

- 8.6 CTP TEAM

- 8.7 Echogen Power Systems

- 8.8 FirstESCO India Pvt. Ltd.

- 8.9 Forbes Marshall

- 8.10 IHI Corporation

- 8.11 John Wood Group

- 8.12 Kanin Energy

- 8.13 Kawasaki Heavy Industries

- 8.14 Mitsubishi Heavy Industries

- 8.15 Primetals Technologies

- 8.16 Promec Engineering

- 8.17 Siemens Energy

- 8.18 Sofinter

- 8.19 Thermax

- 8.20 Turboden