PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1906063

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1906063

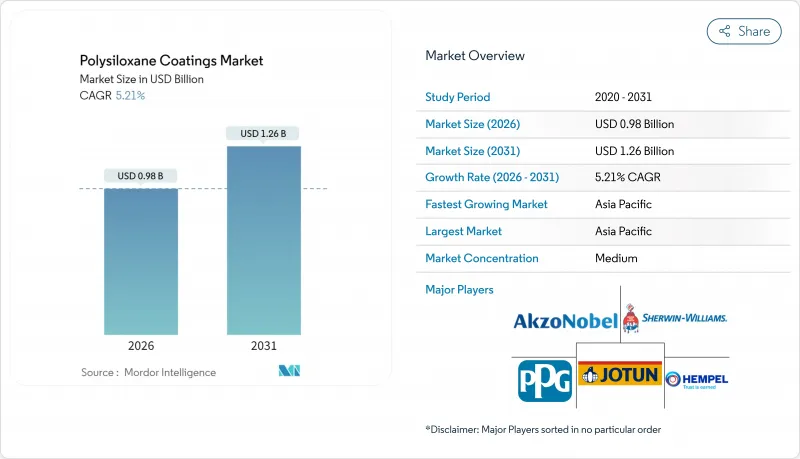

Polysiloxane Coatings - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2026 - 2031)

The Polysiloxane Coatings Market is expected to grow from USD 0.93 billion in 2025 to USD 0.98 billion in 2026 and is forecast to reach USD 1.26 billion by 2031 at 5.21% CAGR over 2026-2031.

The rising specification of these silicone-organic hybrids in harsh marine and energy settings, along with elevated infrastructure spending in emerging economies and tightening global VOC regulations, collectively underpin demand momentum. Specification engineers view polysiloxane systems as an effective path to extend maintenance cycles, cut life-cycle cost, and comply with evolving health and safety norms, an alignment that reinforces premium pricing power. Major suppliers highlight two-coat epoxy-polysiloxane alternatives that replace three-coat zinc-rich epoxy-polyurethane schemes, thereby reducing labor needs at a time of skilled painter scarcity. Meanwhile, ultra-high-solid variations reduce solvent release without sacrificing edge coverage. Competitive emphasis has therefore shifted to resin innovation, acquisition-led portfolio shaping, and region-specific technical service programs that secure repeat orders.

Global Polysiloxane Coatings Market Trends and Insights

Growing Oil and Gas CAPEX in Corrosive Offshore and Shale Assets

Global upstream operators are channeling new capital toward deep-water and shale prospects that expose steel to high concentrations of chloride, CO2, and H2S. Polysiloxane technology provides the required C5 protection in two coats, reducing trimming time on floating production platforms where weather windows narrow each year. Asset owners also cite lower under-film blistering versus conventional epoxies, a benefit that delays costly touch-ups in splash zones. Recent qualified systems have exceeded 15,000 hours of salt-spray testing while maintaining gloss retention above 85% after 3,000 hours of QUV, reinforcing the technology's durability credentials. Offshore contractors, therefore, embed polysiloxane topcoats in standard maintenance specifications for jackets, decks, and flare towers as part of life-extension programs. Service providers emphasize that high film-build capability enables adequate edge protection with one cross-spray pass, easing productivity hurdles created by labor shortages in remote basins.

Public-Private Megaproject Pipelines in Asia and Africa

Governments in China, India, and several African nations are co-funding cross-country pipelines and terminal networks that must withstand humidity swings, desert sand abrasion, and ultraviolet exposure. Polysiloxane systems retain adhesion and flexibility across -40°C to +120°C cycles, reducing the need for shutdowns to recoat above-ground sections. Engineering, procurement, and construction (EPC) consortia largely mandate ISO 12944 C4 or C5 compliance, a threshold that polysiloxane hybrids reach with fewer coats. Local applicators gain speed benefits from faster touch-dry times, a critical factor on linear projects where kilometer-long spreads move daily. Suppliers deepen regional partnerships-exemplified by BASF and Oriental Yuhong-to blend global resin expertise with on-site training that meets local quality standards. Forward schedules for gas pipeline corridors in East Africa and ASEAN suggest a multi-year tailwind for polysiloxane sales into protective segments.

Skilled-Painter Scarcity Inflating Field-Applied Costs

Average hourly wages for NACE-certified sprayers in the United States exceeded USD 50 in 2025, and overtime premiums escalate further during seasonal maintenance peaks. Similar shortages are also evident in Germany and the Netherlands, as an aging workforce retires faster than newcomers enter. Polysiloxane systems require accurate mix ratios and dew-point control, amplifying the impact of labor gaps. Ship-repair yards report bid prices up 15% year-on-year on labor alone, pushing some owners to postpone repaint cycles. Manufacturers counter with single-component or pre-blended kits that reduce on-site handling, but these variants often carry a higher resin cost. Training initiatives led by coating suppliers and trade associations aim to certify new applicators; however, the pipeline will take years to refill, which will mute near-term volume growth.

Other drivers and restraints analyzed in the detailed report include:

- Transition from Solvent-Borne to Ultra-High-Solid Hybrids

- Rapid Expansion of LNG Carrier Fleet

- Regulatory Scrutiny on Cyclic Siloxane By-Products

For complete list of drivers and restraints, kindly check the Table Of Contents.

Segment Analysis

Epoxy-polysiloxane hybrids accounted for the largest share of the polysiloxane coatings market, with a revenue share of 38.86% in 2025. Their dominance stems from the union of epoxy's primer-level adhesion with silicone's UV stability, which together allow a two-layer build to meet ISO 12944 C5-M performance. Field studies on offshore jackets confirm maintenance intervals above 15 years, a result that amplifies total cost-of-ownership savings when labor is scarce. End-users thus perceive price premiums as acceptable, anchoring long-term contracts for platform upgrades and naval refits.

Acrylic-polysiloxane hybrids, although having a smaller base, boast the quickest 5.62% CAGR due to their superior color retention and low yellowing, which appeal to cruise vessels, architectural facades, and bridge girder projects. Strict VOC limits in California and the European Economic Area further steer specifiers toward water-based acrylic-siloxane dispersions that release fewer solvents without sacrificing gloss. Polyester-modified grades carve a niche in chemical plants exposed to acids and alkalis, leveraging ester linkages to boost chemical resistance. Fluorinated polysiloxane blends and ceramic-filled variants target extreme-temperature units and graffiti-prone transit structures, respectively, underscoring a broader trend: resin chemists seek multi-attribute performance to replace multi-coat stacks. Recent lab work on room-temperature-curing emulsifier-free silicone binders reduces hydrolytic stress, suggesting next-generation offerings will merge zero-VOC status with higher mechanical strength.

The Polysiloxane Coatings Market Report is Segmented by Resin Type (Epoxy-Polysiloxane Hybrids, Acrylic-Polysiloxane Hybrids, Polyester-Modified Polysiloxane, and Other Resin Types), End-User Industry (Protective, Marine, and Other End-User Industries), and Geography (Asia-Pacific, North America, Europe, South America, and Middle East and Africa). The Market Forecasts are Provided in Terms of Value (USD).

Geography Analysis

Asia-Pacific captured a 54.88% share of the polysiloxane coatings market in 2025 and is set to log a 6.55% CAGR from 2026-2031, anchored by China's unrivaled shipbuilding scale and South Korea's dominance in LNG vessel construction. Beijing's push for locally built naval ships and the country's 14th Five-Year Plan, which targets 260 GW of offshore wind capacity, intensifies domestic demand for these products. Japan contributes through high-spec chemical carriers and FSRU projects that specify silicone-rich topcoats to resist cargo spillage. India's Sagarmala port upgrade and the growth of modular fabrication yards across ASEAN widen the regional customer pool.

North America holds the second-largest share, driven by the Gulf of Mexico's floating production unit refurbishment, the modularization of Canadian oil sands, and federal infrastructure renewal projects across bridges and airports. The US EPA's aim to clamp VOCs below 275 g/L in industrial maintenance coatings steers asset owners toward ultra-high-solid polysiloxane systems. Regional power-utilities adopt these hybrids for flue-gas desulfurization ducting because silicone backbones withstand acidic condensation cycles. Free-trade logistics under USMCA streamline cross-border resin and pigment supply, lowering lead times for high-build polysiloxane shipments into Mexican offshore EPC hubs.

Europe shows steadier growth yet stays strategically important. North Sea decommissioning and wind-farm repowering generate maintenance coatings work, while Nordic yards fabricate ice-class supply vessels requiring low-temperature cure polysiloxane primers. The upcoming EU cyclic-siloxane restriction drives early conversion to compliant water-based dispersions, making the region a test bed for next-generation formulations. Germany's autobahn bridge renewal program specifies 25-year anti-corrosion performance, a target that epoxy-polysiloxane duplex systems can meet in two layers, thereby curbing lane-closure days. Middle East & Africa and South America emerge as long-term demand centers. Brazil's pre-salt FPSO backlog and UAE's port expansions are likely to adopt polysiloxane technology to meet extended inspection cycles in hot saline environments.

- Akzo Nobel N.V.

- Asian Paints Ltd.

- Hempel A/S

- Jotun

- KISHO Corporation Co.,Ltd

- Metcon Coatings & Chemicals India Private Limited.

- NCP Coatings LLC

- PPG Industries, Inc.

- The Sherwin-Williams Company

- Thomas Industrial Coatings

- Tianjin Jinhai Special Coatings & Decoration Co., Ltd.

- Tikkurila

- Tnemec

- Yung Chi Paint & Varnish MFG. CO.,LTD

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 Introduction

- 1.1 Study Assumptions & Market Definition

- 1.2 Scope of the Study

2 Research Methodology

3 Executive Summary

4 Market Landscape

- 4.1 Market Overview

- 4.2 Market Drivers

- 4.2.1 Growing oil and gas CAPEX in corrosive offshore and shale asset

- 4.2.2 Public-private megaproject pipelines in Asia and Africa

- 4.2.3 Transition from solvent-borne to ultra-high-solid hybrids

- 4.2.4 Surge of modular wind-tower fabrication yards

- 4.2.5 Rapid expansion of LNG carrier fleet

- 4.3 Market Restraints

- 4.3.1 Skilled-painter scarcity inflating field-applied costs

- 4.3.2 Regulatory scrutiny on cyclic siloxane by-products

- 4.3.3 Edge-defect failures under high-temperature cycling

- 4.3.4 Competitive threat from fluoropolymer top-coats

- 4.4 Value Chain Analysis

- 4.5 Porter's Five Forces

- 4.5.1 Bargaining Power of Suppliers

- 4.5.2 Bargaining Power of Consumers

- 4.5.3 Threat of New Entrants

- 4.5.4 Threat of Substitute Products & Services

- 4.5.5 Degree of Competition

5 Market Size & Growth Forecasts (Value)

- 5.1 By Resin Type

- 5.1.1 Epoxy-Polysiloxane Hybrids

- 5.1.2 Acrylic-Polysiloxane Hybrids

- 5.1.3 Polyester-Modified Polysiloxane

- 5.1.4 Other Resin Types

- 5.2 By End-user Industry

- 5.2.1 Protective

- 5.2.1.1 Oil and Gas

- 5.2.1.2 Power

- 5.2.1.3 Infrastructure

- 5.2.2 Marine

- 5.2.3 Other End-user Industries

- 5.2.1 Protective

- 5.3 By Geography

- 5.3.1 Asia-Pacific

- 5.3.1.1 China

- 5.3.1.2 India

- 5.3.1.3 Japan

- 5.3.1.4 South Korea

- 5.3.1.5 ASEAN Countries

- 5.3.1.6 Rest of Asia-Pacific

- 5.3.2 North America

- 5.3.2.1 United States

- 5.3.2.2 Canada

- 5.3.2.3 Mexico

- 5.3.3 Europe

- 5.3.3.1 Germany

- 5.3.3.2 United Kingdom

- 5.3.3.3 Italy

- 5.3.3.4 France

- 5.3.3.5 Spain

- 5.3.3.6 NORDIC Countries

- 5.3.3.7 Rest of Europe

- 5.3.4 South America

- 5.3.4.1 Brazil

- 5.3.4.2 Argentina

- 5.3.4.3 Rest of South America

- 5.3.5 Middle East and Africa

- 5.3.5.1 Saudi Arabia

- 5.3.5.2 United Arab Emirates

- 5.3.5.3 South Africa

- 5.3.5.4 Rest of Middle East and Africa

- 5.3.1 Asia-Pacific

6 Competitive Landscape

- 6.1 Market Concentration

- 6.2 Strategic Moves

- 6.3 Market Share/Ranking Analysis

- 6.4 Company Profiles (includes Global level Overview, Market level overview, Core Segments, Financials as available, Strategic Information, Market Rank/Share, Products & Services, Recent Developments)

- 6.4.1 Akzo Nobel N.V.

- 6.4.2 Asian Paints Ltd.

- 6.4.3 Hempel A/S

- 6.4.4 Jotun

- 6.4.5 KISHO Corporation Co.,Ltd

- 6.4.6 Metcon Coatings & Chemicals India Private Limited.

- 6.4.7 NCP Coatings LLC

- 6.4.8 PPG Industries, Inc.

- 6.4.9 The Sherwin-Williams Company

- 6.4.10 Thomas Industrial Coatings

- 6.4.11 Tianjin Jinhai Special Coatings & Decoration Co., Ltd.

- 6.4.12 Tikkurila

- 6.4.13 Tnemec

- 6.4.14 Yung Chi Paint & Varnish MFG. CO.,LTD

7 Market Opportunities & Future Outlook

- 7.1 White-space and Unmet-need Assessment