PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1643157

PUBLISHER: Mordor Intelligence | PRODUCT CODE: 1643157

Asia Industry 4.0 - Market Share Analysis, Industry Trends & Statistics, Growth Forecasts (2025 - 2030)

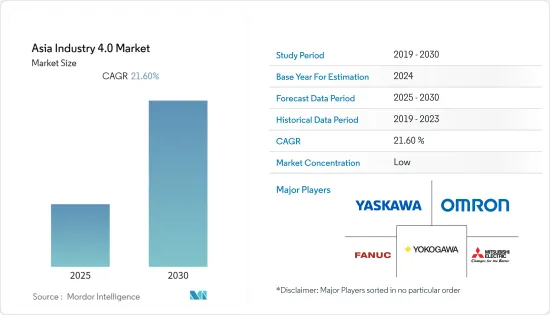

The Asia Industry 4.0 Market is expected to register a CAGR of 21.6% during the forecast period.

Key Highlights

- Asia has been an early adopter of technological advancements. The market in these developing economies poses a key advantage in implementing industrial automation since they are not tormented by rebuilding legacy automation systems and machine investments.

- Robotics is crucial to China's smart manufacturing ambitions and comprehensive industrial policy. A slightly different variation in the configuration of the government agencies (with MIIT again at the helm) announced a related 5-year development plan for the robotics industry in 2022 as the release of the smart manufacturing development plan. The fast pace toward the 5G-powered industry revolution 4.0 is on, and China has a strong head start.

- According to Huawei, critical communications solutions based on industrial-grade private wireless offer unimaginable possibilities to the power Industry 4.0 use cases, from machine remote control to cloud robotics, process automation, predictive asset maintenance, assisted/autonomous vehicles, CCTV monitoring, and mission-critical push-to-talk and push-to-video, all on a single network infrastructure.

- Technological changes in the last decade revolutionized the organization of industrial production, influencing production processes and supply chains. Industry 4.0, hereafter, has integrated new technologies such as AI, IoT, ML, cloud computing, and analytics into manufacturing production operations and processes, propelling a new era of smart manufacturing. Digital technologies in manufacturing promote automation and self-optimization, leading to the efficiency of operations across the value chain in the region.

- Industry revolution 4.0 is fuelled by four significant components: hyper-efficient processing technology (chips), widespread internet penetration, machine learning, and artificial intelligence. While the waves of automation due to past industrial revolutions popularised the mass-homogeneous production systems, Industry 4.0 brings more customized industrial production to the fore. With Industry 4.0, new production models are emerging where 3-D printers, automated systems, robots, data exchanges, and data exchanges are used effectively in an environment of smart factories. This will make the production processes lean and flexible, enabling optimum resource utilization.

- As Asian countries experienced strict lockdowns during the COVID-19 pandemic, the developments concerning Industry 4.0 were impacted for 6-8 months. Factory closures and shifts in investments were primary factors for the same. Multiple vendors of factory automation solutions shut their facilities in the wake of curbing the spread of the virus. Innovative technologies, such as artificial intelligence (AI), mass automation, industrial communications, big data, robotics, and 3D printing, are transforming the regional manufacturing landscape post-pandemic.

Asia Industry 4.0 Market Trends

Manufacturing Industry to Hold Significant Market Share

- The manufacturing industry is a key contributor to the economy of the Asia-Pacific region and is presently undergoing a rapid technological digital transformation. Manufacturing firms are increasingly moving their operations to Southeast Asia to cut costs due to inexpensive workforce availability.

- Industrial IoT (IIoT) is being adopted significantly in the region of the manufacturing industry. Further, computer and network technologies, such as cloud computing and mobile computing, are also being implemented in these systems, which is expected to boost the adoption of advanced technologies in the country.

- According to MOSPI, in January 2022, the index of industrial production for the manufacturing sector across India in the financial year of 2021 stood at 116.9. In India, the manufacturing industry has gradually emerged as one of the high-growth sectors. The 'Make in India' program places India on the global map as the manufacturing hub provides international recognition to the Indian economy. Moreover, manufacturing giants such as GE, Siemens, HTC, Toshiba, and Boeing, have either set up or are setting up manufacturing plants in India. These trends are expected to boost the adoption of Industry 4.0 in their plants in the future.

- The trend is also augmented by Mitsubishi's investment of more than JPY 30 billion to increase the output of its factory automation system products to meet growing demand. Further, the company plans to establish a new plant near its existing facility in Aichi Prefecture and rebuild an existing plant in Nagoya to bolster production capacity. Similar initiatives are expected to boost the adoption of Industry 4.0 technologies across the region's manufacturing industry.

Japan to Witness Significant Growth

- Japan has been transforming into an automated industrial economy and adopting Industry 4.0 faster in the Asia-Pacific region. The government of Japan has been emerging as a manufacturing hub for automation products and supplies to the regional markets in the Asia-Pacific region.

- The presence of multiple automobile manufacturers, the food processing industry, and the electronic product manufacturing industry makes Japan an essential market in the region. The country with highly-developed automation technologies and a robotic sector can be regarded as the global leader in the automation of production processes and employment of robotics.

- The manufacturing industry in Japan contributes around 20% to the country's nominal Gross Domestic Product (GDP). According to the International Monetary Fund, the country's manufacturing sector gained significant ground by implementing the Integrated Manufacturing Tax (ITC). Industry 4.0 in Japan has led to the development of advanced technologies, such as collaborative and AI-enabled robots. These have allowed companies to improve their efficiency and reduce errors by implementing them in various processes. Increasing workplace safety regulations and improving production capabilities are expected to drive demand for robotic systems.

- The increasing number of digitization initiatives in the country and the emergence of Industry 4.0 are expected to provide promising opportunities for the market. Even with the presence of various factors that have affected the country's economy, it has still managed to grow steadily. Moreover, the electronics and automotive sectors are Japan's most productive manufacturing sectors, which rely heavily on automation daily. This factor is likely to drive digital transformation and automation in the manufacturing processes of various goods.

Asia Industry 4.0 Industry Overview

The Asian Industry 4.0 market is very competitive. The market is highly concentrated due to the presence of various small and large players. Some of the significant players in the market are Mitsubishi Electric, Omron Corporation, Yokogawa Electric Corporation, Fanuc Corporation, Yaskawa Electric Corporation, Robert Bosch GmbH General Electric Company, and many more.

In February 2022, Mitsubishi Electric Asia's Factory Automation & Industrial Division joined Singapore's ARTC as a Tier 2 Member. The Advanced Remanufacturing and Technology Centre (ARTC), a contemporary platform built upon solid public-private partnerships company, is expanding its foothold around the Industrial Internet of Things (IIoT) services by developing integrated solutions for manufacturing companies to accelerate digital transformation and scaling up its adoption of Industry 4.0 technologies in response to Singapore's Smart Industry Readiness Index.

In February 2022, the Japanese manufacturing group Mitsubishi Electric inducted the country mate NTT Docomo into its new Industry 4.0 alliance in Thailand to offer private 5G with smart manufacturing solutions from other partners. Mitsubishi Electric called it the first case of 5G with Japanese equipment in Thailand. The companies will build a new private 5G set up in the country by the end of the summer, strategically located for the government's Thailand 4.0 project.

Additional Benefits:

- The market estimate (ME) sheet in Excel format

- 3 months of analyst support

TABLE OF CONTENTS

1 INTRODUCTION

- 1.1 Study Assumptions and Market Definition

- 1.2 Scope of the Study

2 RESEARCH METHODOLOGY

3 EXECUTIVE SUMMARY

4 MARKET INSIGHTS

- 4.1 Market Overview

- 4.2 Industry Attractiveness - Porter's Five Forces Analysis

- 4.2.1 Bargaining Power of Suppliers

- 4.2.2 Bargaining Power of Consumers

- 4.2.3 Threat of New Entrants

- 4.2.4 Threat of Substitutes Products

- 4.2.5 Intensity of Competitive Rivalry

- 4.3 Impact of COVID-19 on the Market

5 MARKET DYNAMICS

- 5.1 Market Drivers

- 5.1.1 Favorable Governmental Initiatives and Collaborations Between Stakeholders in the Region

- 5.1.2 Growth in Demand for Industrial Robotics

- 5.1.3 Digital Transformation Initiatives Undertaken by SMEs

- 5.2 Market Challenges

- 5.2.1 Relative Lack of Awareness on the ROI Related to Adoption of Industry 4.0

- 5.2.2 Need For Significant Investments to Realize Benefits

- 5.2.3 Workforce and Standardization Related Challenges

6 MARKET SEGMENTATION

- 6.1 By Technology Type

- 6.1.1 Industrial Robotics

- 6.1.2 IIoT

- 6.1.3 AI and ML

- 6.1.4 Blockchain

- 6.1.5 Extended Reality

- 6.1.6 Digital Twin

- 6.1.7 3D Printing

- 6.1.8 Other Technology Types

- 6.2 By End-user Industry

- 6.2.1 Manufacturing

- 6.2.2 Automotive

- 6.2.3 Oil and Gas

- 6.2.4 Energy and Utilities

- 6.2.5 Electronics and Foundry

- 6.2.6 Food and Beverage

- 6.2.7 Aerospace and Defense

- 6.2.8 Other End-user Industries

- 6.3 By Country

- 6.3.1 China

- 6.3.2 South Korea

- 6.3.3 Japan

- 6.3.4 India

- 6.3.5 Indonesia

- 6.3.6 Rest of Asia

7 COMPETITIVE LANDSCAPE

- 7.1 Company Profiles

- 7.1.1 Mitsubishi Electric

- 7.1.2 Omron Corporation

- 7.1.3 Yokogawa Electric Corporation

- 7.1.4 Fanuc Corporation

- 7.1.5 Yaskawa Electric Corporation

- 7.1.6 Robert Bosch GmbH

- 7.1.7 General Electric Company

- 7.1.8 ABB Ltd

- 7.1.9 Cisco Systems Inc.

- 7.1.10 Intel Corporation

- 7.1.11 IBM Corporation

- 7.1.12 Denso Corporation

8 INVESTMENT ANALYSIS

9 FUTURE OF THE MARKET